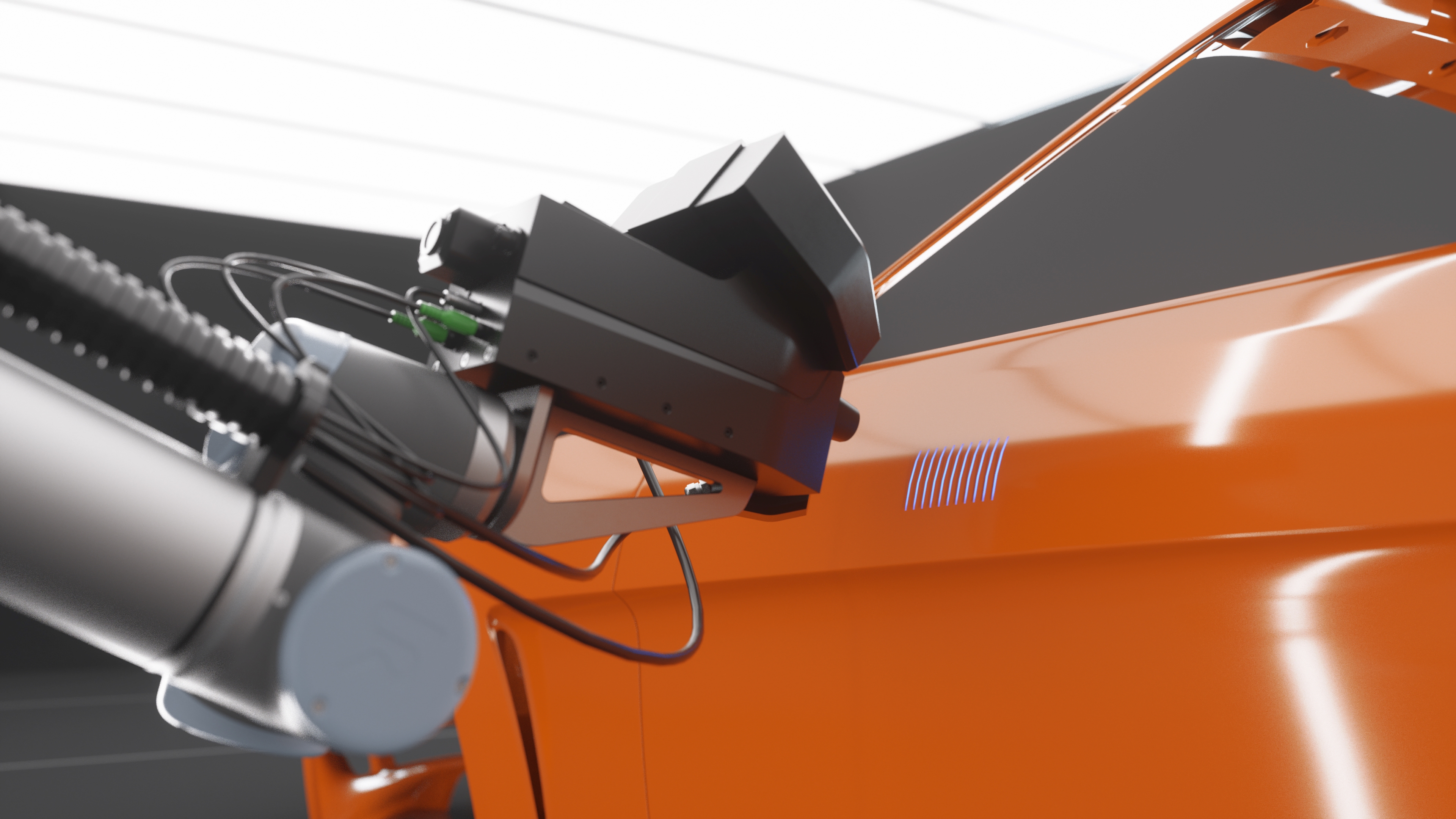

Fraunhofer Heinrich Hertz Institute HHI, Berlin, and TOPTICA Photonics AG, Graefelfing, present in the Control exhibition a terahertz platform of the latest generation that achieves a total bandwidth of 6.5 THz and a peak dynamic range of more than 95 dB in less than 20 s is presented. For in-line testing with sub-second measurement times, the usable bandwidth still remains well above 5 THz. This system is a result of an intensive collaboration between the two partners, with TOPTICA Photonics AG being a dedicated terahertz system provider, and the Fraunhofer Heinrich Hertz Institute HHI, which specializes in the development of high-performance terahertz sensors and systems. The terahertz platform can be combined with a fully automated layer thickness measurement system for non-contact inspection of paint and coatings (see Fig. 1). Multilayer coatings consisting of up to five layers with individual thicknesses between 5 µm – 80 µm can be resolved. Thickness values are automatically calculated from the measured pulse trace by using a transfer matrix algorithm. The accuracy of the thickness measurement is better than 0.5 µm and the reproducibility of consecutive measurements is higher than 1 %. Hence, this measurement system is an important step for bringing terahertz sensors into a wide range of industrial applications.

Contact-free Terahertz Thickness Measurement System

A significant market potential is up and coming for the industrial employment of terahertz instrumentation. Just a few years ago, the application of terahertz radiation seemed obscure at best. If experts were asked for »killer applications«, none would have been able to name at least one. Now, however, terahertz technologies show significant market potential. The success of the technology is based on developments with fiber-coupled light sources as well as a new generation of compact and cost-effective systems. Applications in the field of civil safety, nondestructive testing and industrial quality control all profit from a new generation of terahertz systems.

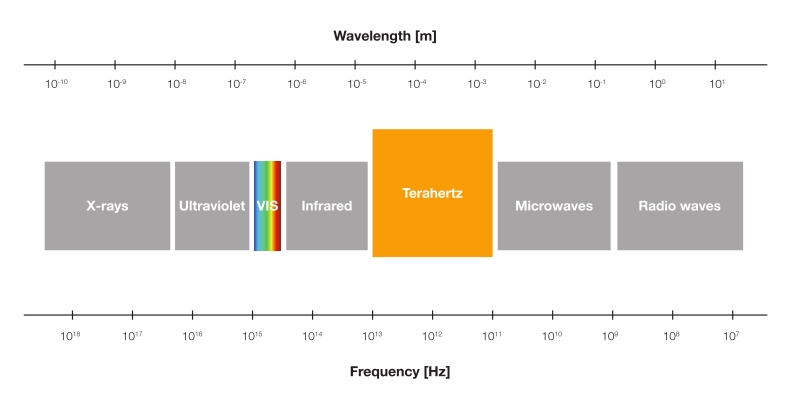

The terahertz spectrum contains frequencies from 100 GHz to 10 THz (wavelengths between 3 mm and 30 µm, see Fig. 2) and fills a gap between microwaves and far infrared. The generation of terahertz radiation can be achieved using a multitude of techniques. The applications described below use opto-electronic sources that rely on the conversion of near infrared laser light to terahertz pulses. Compared to alternative techniques, e.g. frequency multipliers or quantum cascade lasers, optoelectronic systems unite a high robustness, a compact footprint and especially the ability to access a very broad spectral range.

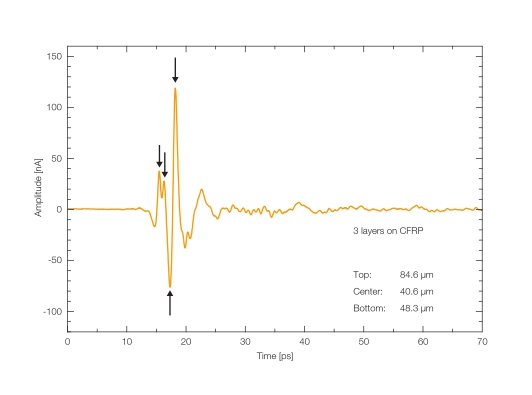

In particular, terahertz time-domain systems are relevant for non-contact thickness measurements of thin, optically opaque layers, e.g. in the quality control of plastic parts or the inspection of paint and coating layers. Terahertz measurements in the time-domain generally employ pulsed sources. These systems use a laser that emits short infrared pulses with a duration of 50 fs - 100 fs. The laser illuminates a photoconductive switch and creates short current pulses. Following the Fourier theory, those short pulses contain high (i.e. terahertz) frequency components. The best photoconductive switches currently available are based on InGaAs-semiconductor material and achieve a measurable bandwidth of up to 7 THz. The measuring principle of terahertz time domain systems is similar to echolocation: terahertz pulses are focused on the layer under inspection and the top and bottom surfaces each reflect a part of the incident pulse. If the refractive index of the material is known, one can calculate the thickness of the layer based on the time-of-flight of the pulses. This method also works with multi-layered surfaces, as long as the individual materials have a different refractive index (see Fig. 3).

Compared to existing techniques, terahertz technology has fundamental advantages: in contrast to magneto-inductive sensors, terahertz systems can measure the thickness of coatings on both metallic and non-conducting substrates. In contrast to x-ray systems, terahertz radiation is non-ionizing and, thus, does not require any safety precautions for in-line applications. Third, terahertz systems can resolve multiple layers in a single measurement.