What is heat flow thermography?

Heat flow thermography is a non-destructive testing method that can be used to detect defects in components beneath the surface that are not externally visible. The basis of the procedure is the analysis of the heat flow or the thermal conductivity in the components. The heat flow thermography is based on imaging. The advantages are the high inspection and the relatively easy automation capacity.

How does heat flow thermography work?

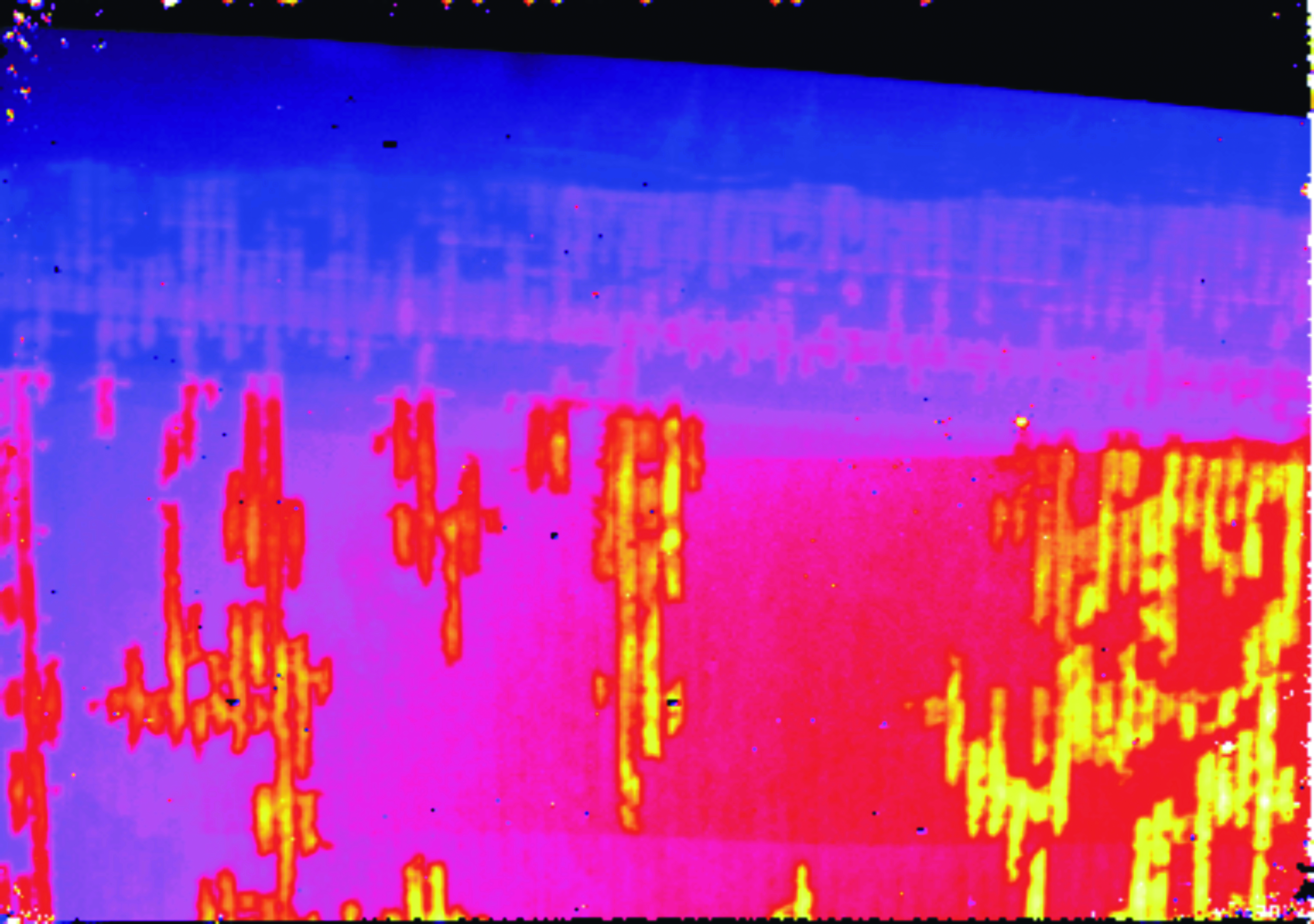

For the examination the test object has to be warm or heated up. The heating can be either impulse-like or periodic, or the intrinsic heat can be used if a component comes exits the production process already heated. In the subsequent cooling phase, the temperature distribution on the surface of the component is observed with an infrared camera. If there are defects in the material (bubbles, blowholes, cracks, delamination, etc.), the heat flow is disturbed, which becomes visible on the surface in form of temperature differences. The temperature differences can be detected and evaluated by means of the thermographic camera.