At Control 2023, the Fraunhofer Institute for Digital Media Technology IDMT, Ilmenau, Germany, will present a method for acoustic quality assurance based on sound analysis and artificial intelligence, which can provide a profitable addition to optical testing methods when these reach their limits.

Ensure quality, stabilize processes, understand artificial intelligence

AI-based acoustic monitoring (amo) can provide great added value in process monitoring, in-line and end-of-line product quality control, as well as predictive maintenance applications. In production, problems regarding unexpected machine downtime, production of poor or destroyed products, and low automation rates can be solved by using amo.

The goals of acoustic monitoring are the optimization of the user's production, stabilizing processes, avoiding recourse, and reducing faulty production.

AI hears and classifies errors correctly

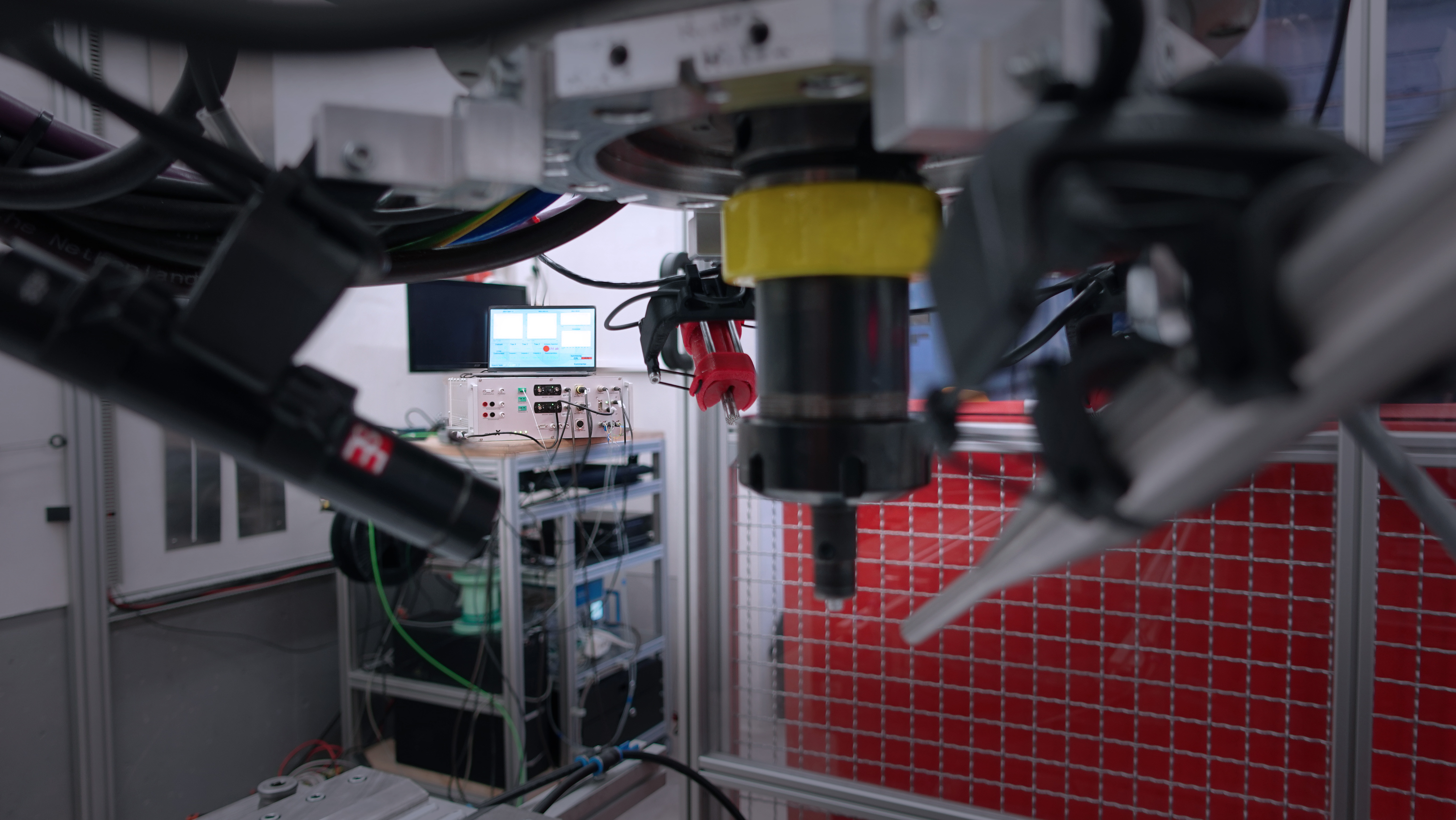

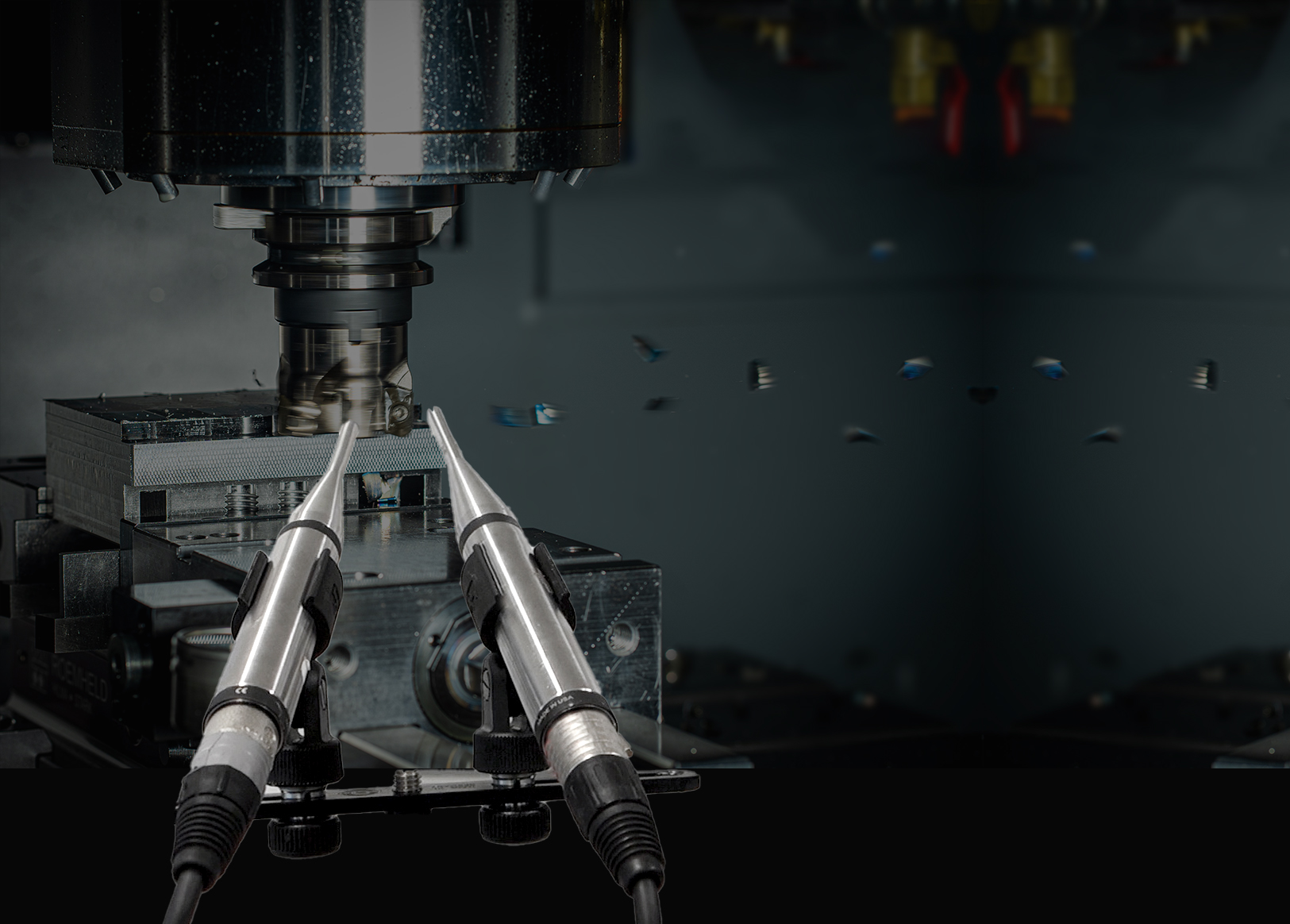

The successful use of the innovative test method has already been demonstrated in the inline quality control of weld seams. Research is currently being conducted into approaches for monitoring different manufacturing processes, including those from the fields of welding and machining. Expert knowledge on suitable sensor setups, sensor data fusion, the processing of sensor data without connection to an external cloud, and energy-efficient AI models play a significant role in all targeted approaches.

Principle demonstrator for acoustic event detection (AED)

The new acoustic monitoring system will be demonstrated at the Control booth using an air hockey table. Three pucks are used, which are made of different materials and cause different "pling" sounds as soon as they hit the border of the game device. During play, these acoustic signals occur frequently and irregularly and can be analyzed and classified using machine learning techniques, even in acoustically challenging environments.