What is acoustic quality testing?

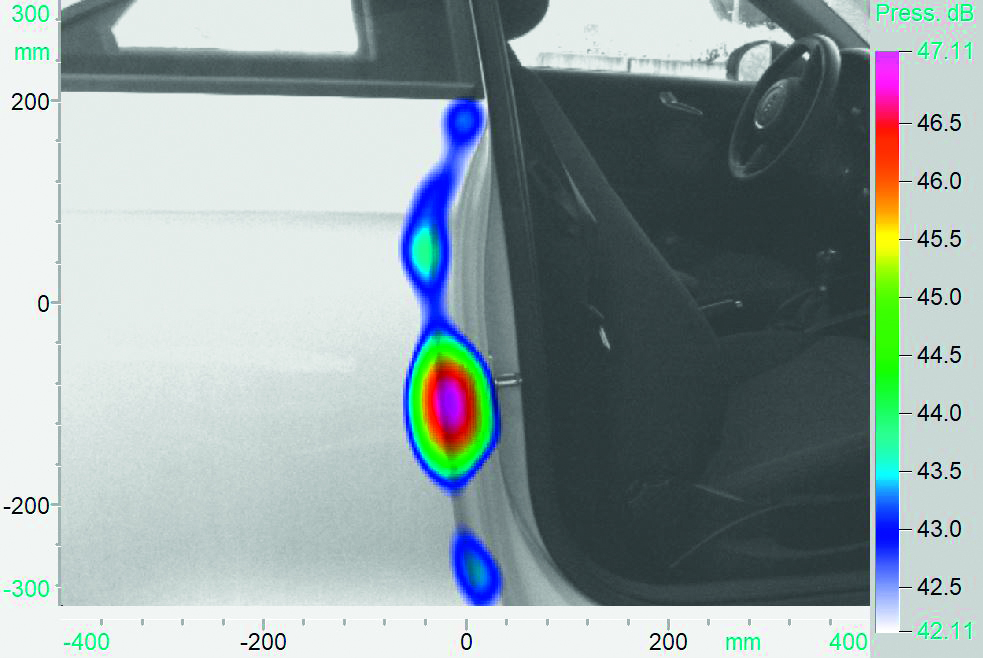

In acoustic quality inspection, the (body) sound of objects or processes is recorded, analyzed and evaluated in order to draw conclusions about the quality of the object.

When components are acoustically stimulated they produce a typical sound that can be used to detect inhomogeneities, cracks orinclusions in the component. In other words, certain natural oscillations develop when a body is (acoustically) stimulated; these natural oscillations are influenced by "deviations" (e.g. defects such as cracks), provided that the defect significantly affects the structural properties of the component.

Even moving or rotating parts, as in machines, systems or motors, have specific operating noises when they function properly. A deviating noise behavior thus indicates a changed functionality or a faulty process.

The resulting signals are recorded and subsequently evaluated and interpreted. For the evaluation and interpretation of the acquired sensor signals, methods from pattern recognition or based on artificial intelligence or machine vision can be used.