Quality assurance with image processing

Numerous Fraunhofer institutes research and develop in the field of image processing and optical or acoustic testing for quality assurance. At the Control 2024 stand, which is coordinated by the Fraunhofer Vision Business Unit, current new developments from various fields will again be on display.

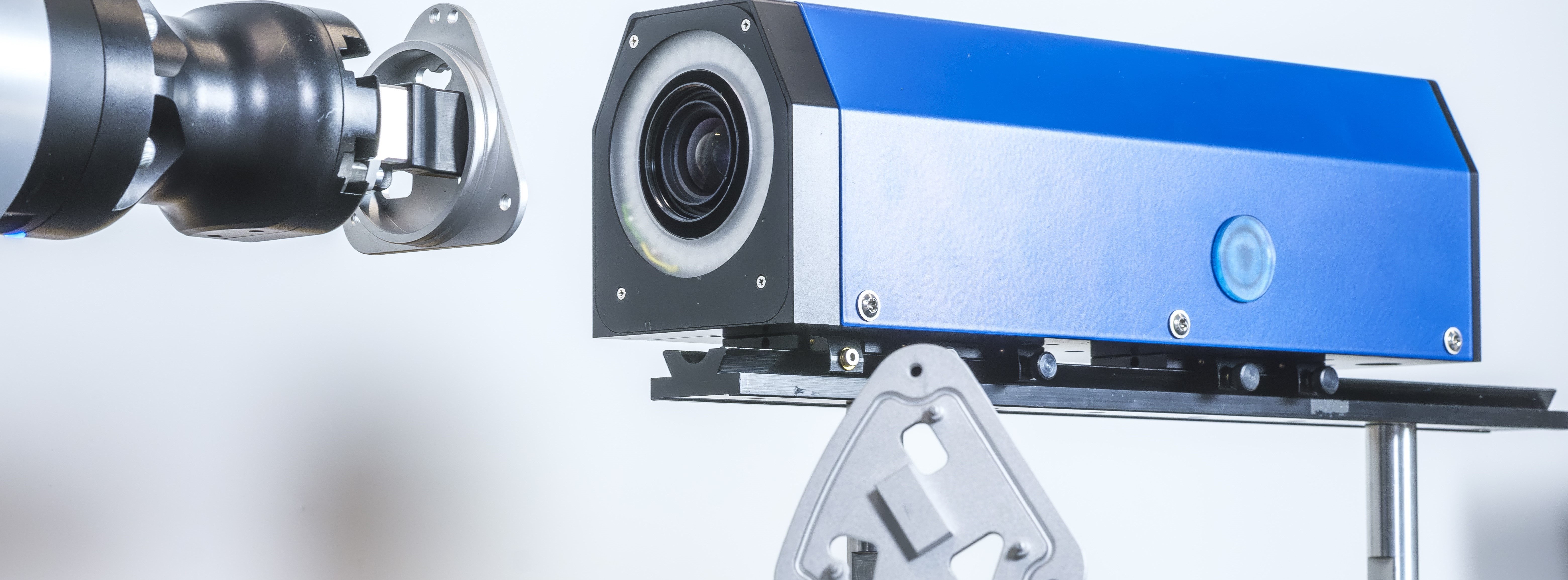

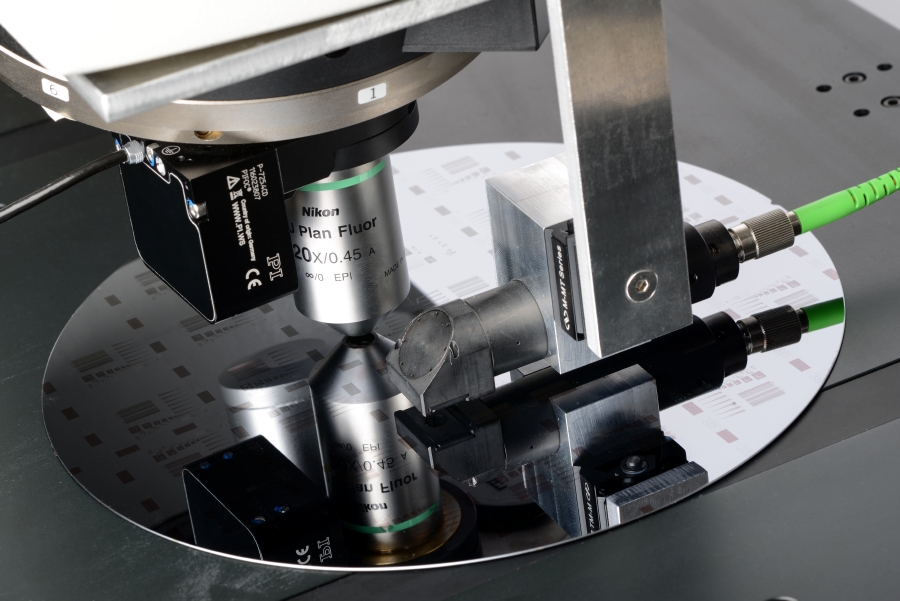

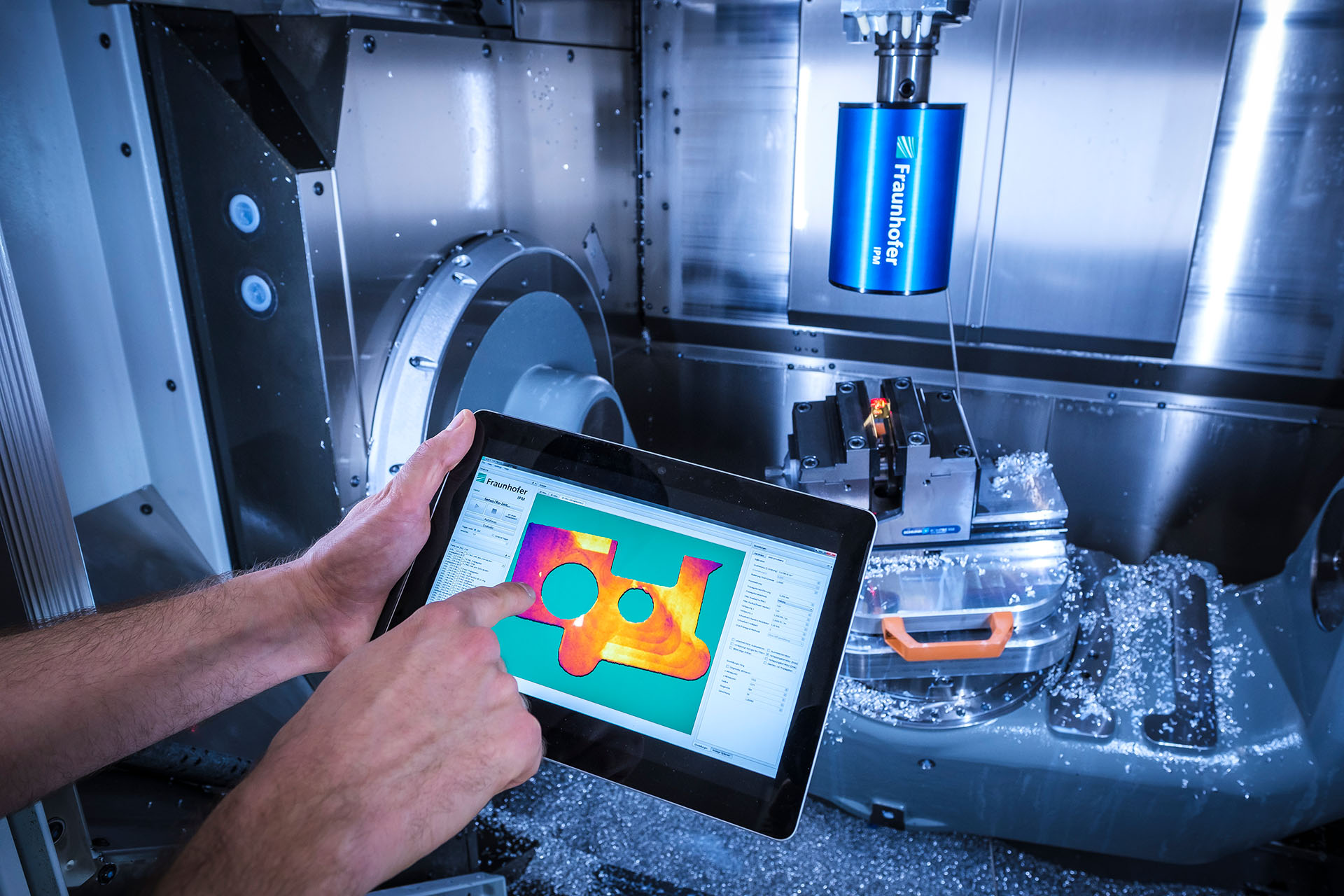

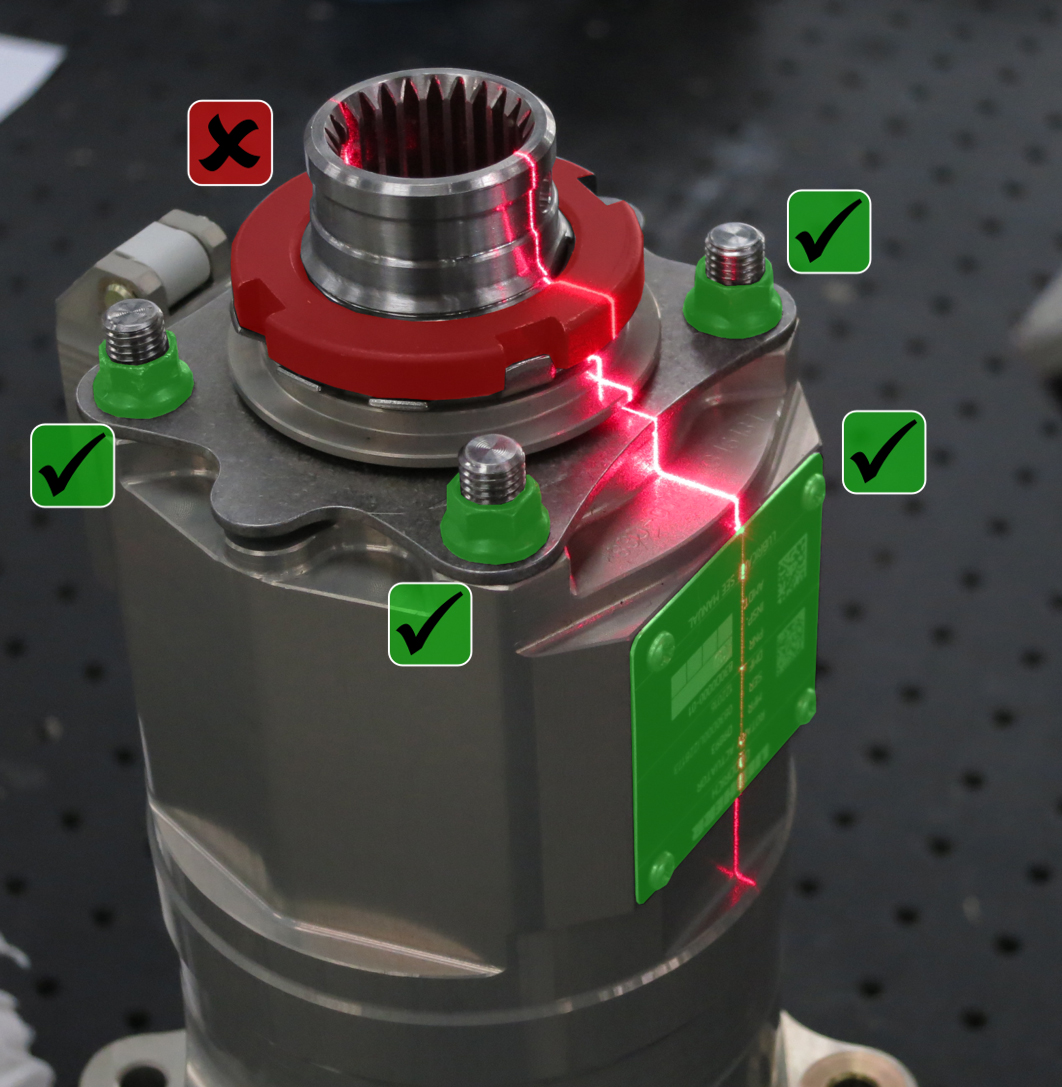

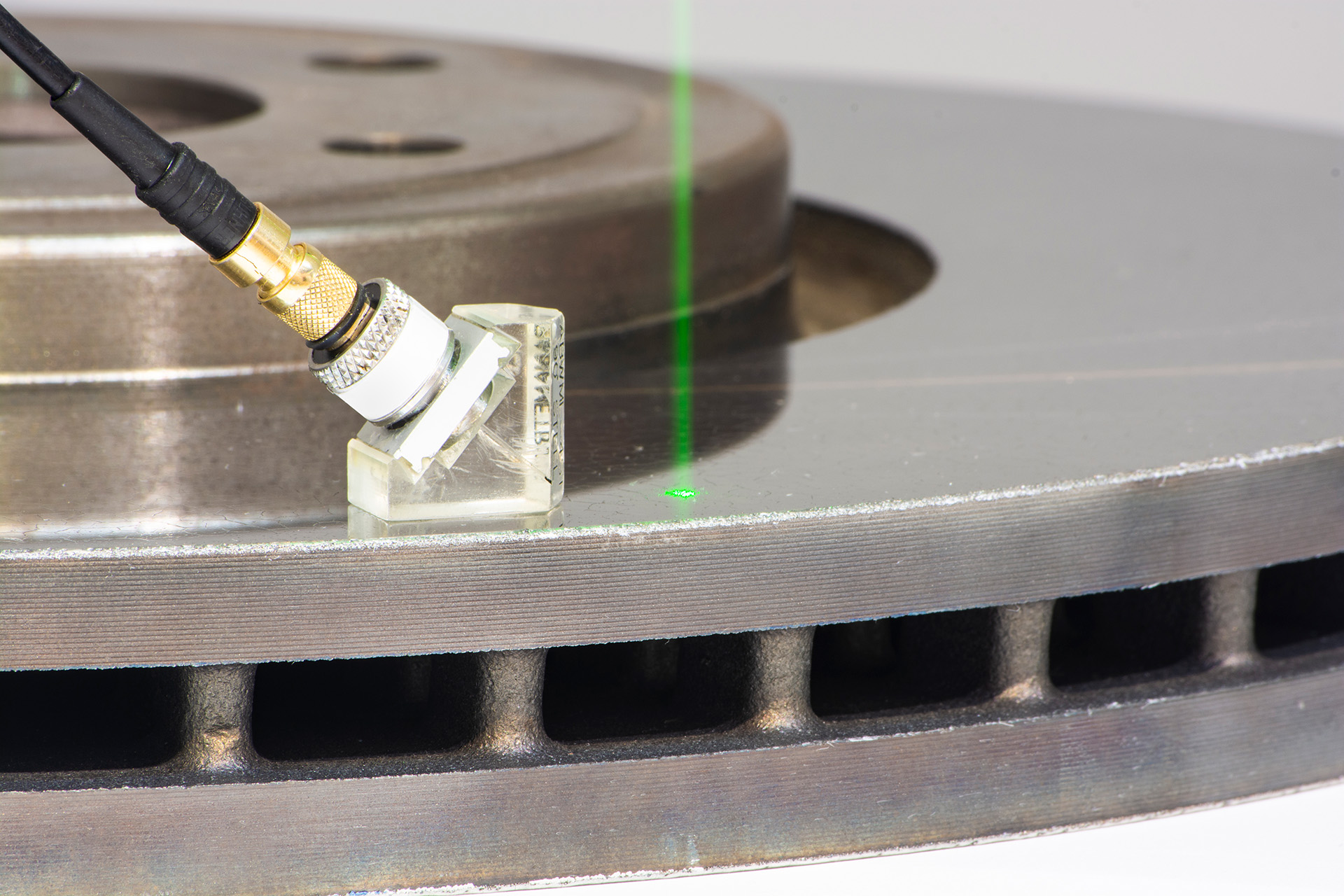

This year, we will present exhibits from the fields from the fields of surface inspection, optical 3D metrology, inline measuring and testing, component identification and augmented reality. New developments in the field of non-destructive testing with technologies such as X-ray computed tomography, terahertz and ultrasound will also be on display.

Other topics are acoustic monitoring of production and laser acoustics.

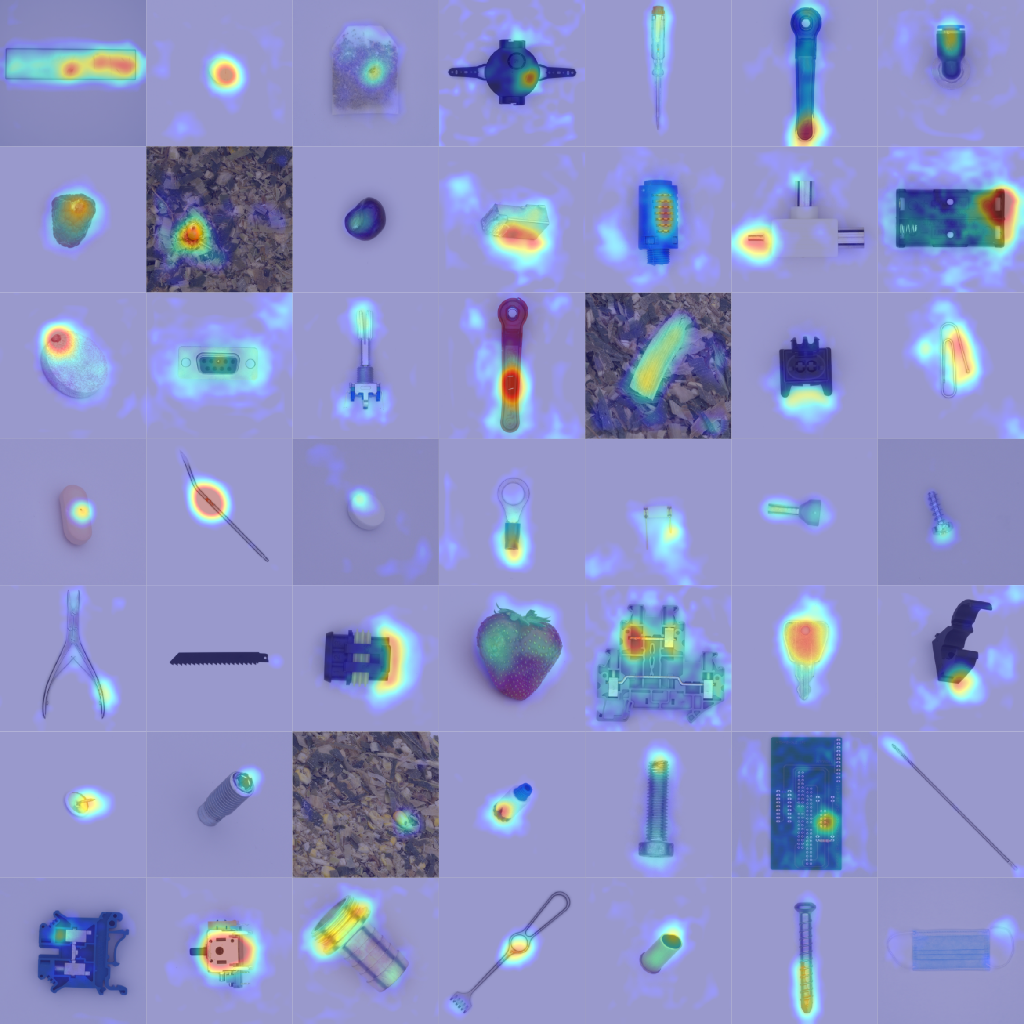

Numerous exhibits work with artificial intelligence or machine learning methods, so that the visitors will be able to get an overview of respective trends.

The Fraunhofer institutes' systems and solutions are used in numerous industries such as automotive and automotive suppliers, mechanical and plant engineering, aviation, plastics, semiconductors, but especially in future industries such as battery and fuel cell production or recycling. The fields of robotics, automation technology, process technology and sensor technology are also addressed.