As a contact point, the Central Office of Fraunhofer's Business Unit Vision offers competent advice to interested parties and potential customers, as well as answers to all questions relating to image processing. The management of the Central Office supports and coordinates the exchange of information and knowledge between the members of the network and initiates projects.

Imparting of Projects

The Business Unit Vision at Fraunhofer pursues its main goal of making new developments accessible to customers in the industry serving as their initial contact point. We can provide turn key solutions including automated handling systems.

Training and Further Education

It is not always easy to decide which quality assurance testing method for the user is best-suited because for most applications, image processing systems are still not off-the-shelf products. Often, it is necessary to choose from a wide range of different measuring methods depending on which is best-suited for requirements, such as material properties, measuring accuracy or permissible test time. The training and further education offered by the Fraunhofer Business Unit Vision can assist decision-making.

Publications

The Guideline Series

Publications are a very important tool to assist potential users to gain insight into the complex field of image processing. The Vision guideline series comprises about a dozen volumes at the moment. Each volume focuses on a specific topic of industrial image processing and describes the potentiality of the technology in several fields of application as simply and concretely as possible. The »Manual of Industrial Image Processing«, which is more than 500 pages strong, has been republished in 2017 and completes the guideline series of Fraunhofer's Business Unit Vision.

The 3D Measuring Technology Market Study

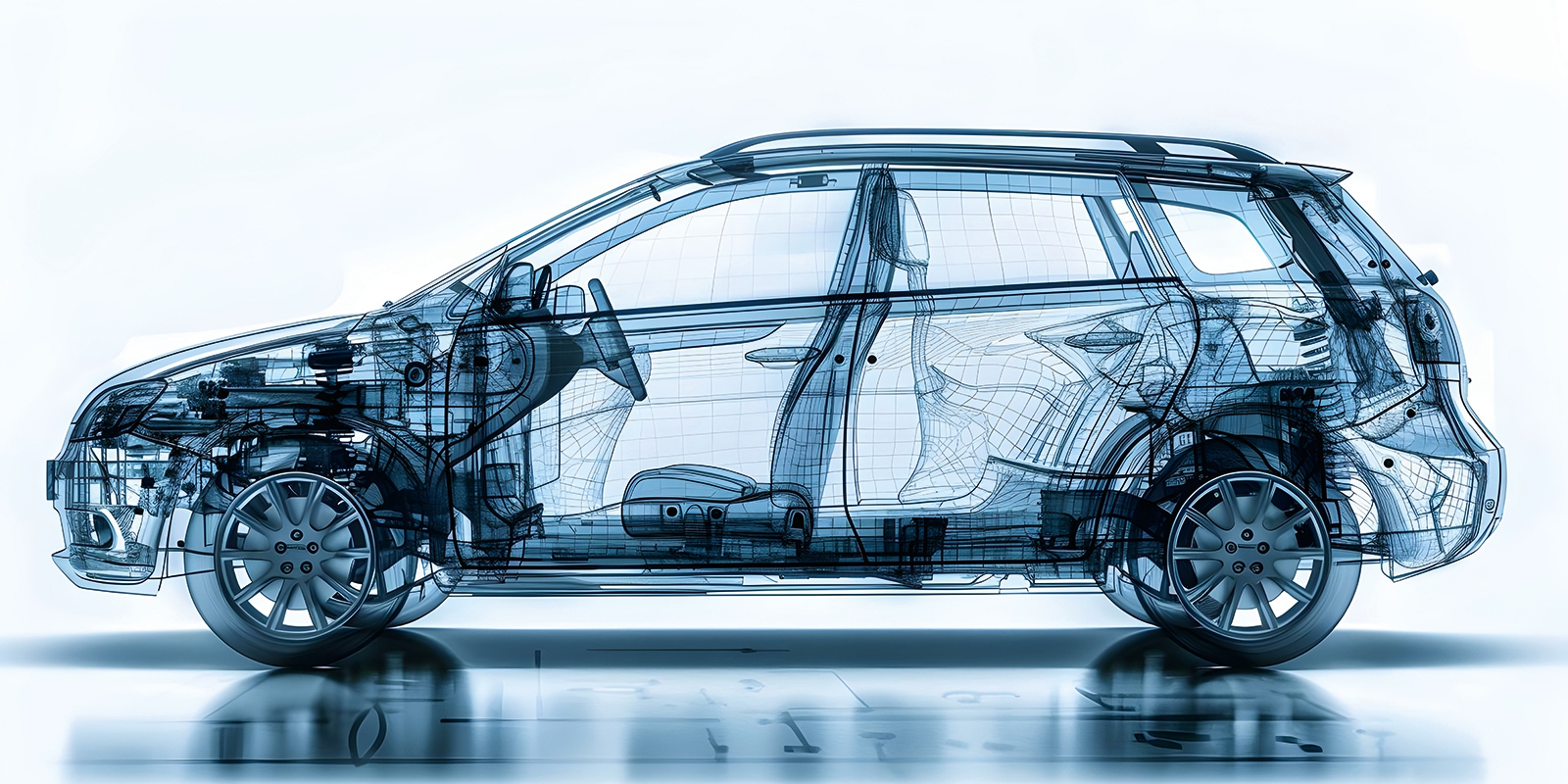

The long-term Market Study »3D Measuring Technology in the German Automotive and Supplying Industry« of Fraunhofer's Business Unit Vision was conceived as a combined quantitative and qualitative analysis to offer support to users and suppliers of 3D measuring technology. Furthermore, it is beneficial to decision makers, who require this type of market relevant information intended for the practical application of technologies in the industrial environment.

The study offers a differentiating view of new optical 3D measurement technologies in contrast to traditionally applied tactile methods. The main issues covered are the description of typical measurement requirements and objects, details of the measurement procedure, information about user behaviour, as well as potential improvements concerning hardware, software and service.

Participation in Trade Fairs

The Central Office coordinates the participation in trade fairs of the Fraunhofer Business Unit Vision members. Every year at the trade fair in Stuttgart named Control, the Fraunhofer presents a new range of special topics focusing on image processing and measuring systems designed for production quality assurance.

In cooperation with the company P. E. Schall GmbH & Co. KG the Business Unit Vision at Fraunhofer has also organized the Special Show »Non-Contact Measurement Technology« at the Control since 2006. The Special Show illustrates the productivity of the contactless measuring technology by means of selected exhibits. Furthermore, it contributes to increased transparency, acceptance and further dissemination of new technologies.

Fraunhofer Business Unit Vision – A Research Network for Industrial Quality Assurance

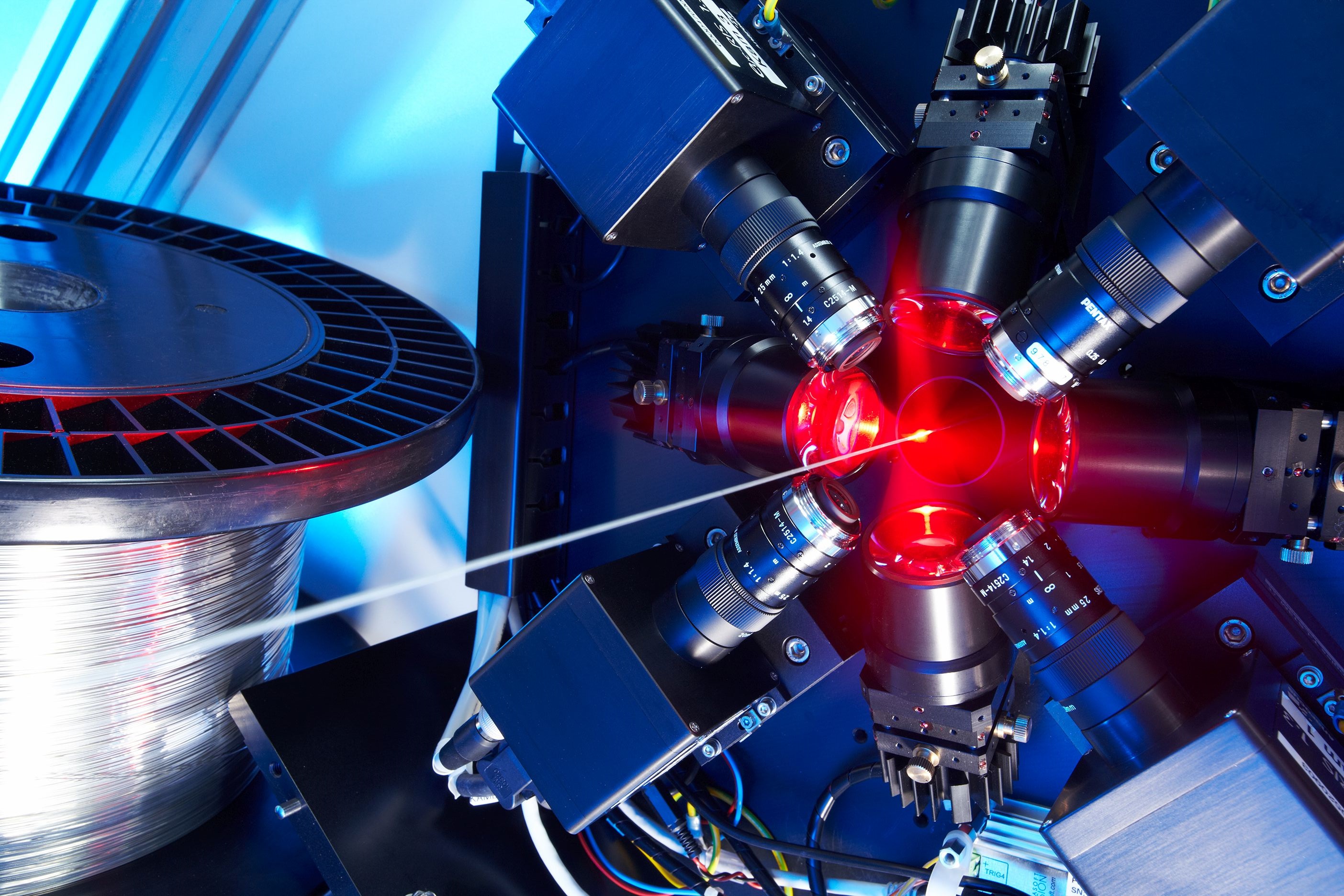

Automatic image processing and machine vision are basic activities of the Business Unit Vision Institutes within Fraunhofer. The main goal of Fraunhofer's Business Unit Vision is the development of new or improved devices for industrial inspection. Video cameras, infrared cameras as well as X-ray cameras are used for imaging. We can provide turn key solutions including automated handling systems. In finding solutions for each project our customers' options are expanded by the exchange of knowledge and experience between the Institutes involved in the network. This is further complimented by an even wider network of related companies and universities with which the Business Unit Vision at Fraunhofer works.

Training Workshops

It is not always easy to decide whether or not a new technology is well-suited for your applications. Our two-day training workshops can help clarify the decision process. In addition to the conveyance of basic theoretical principles and the introduction of example solutions, our workshops offer the opportunity to get hands-on experience of inspecting your own sample parts using the methods and technologies learned on the workshop. Currently the following workshops are being offered (in German only):

- Industrial X-ray Technology

- Optical 3D Measuring

- Heat Flux Thermography for the Analysis of Invisible Defects

- Inspection and Characterization of Surfaces

If you're interested, check our »News«-column on the homepage or subscribe to our e-mail update.