What is industrial X-ray technology?

Industrial X-ray technology is a non-destructive testing method that can be used to detect and characterize structures of any complexity hidden inside materials with high qualitative and quantitative accuracy. X-ray inspection has become inline-capable over the last years, so X-ray inspection systems can also be used in the production cycle.

How does industrial X-ray technology work?

Electromagnetic radiation in the energy range between 5 keV and 10 MeV is able to penetrate solid (or liquid) materials and is subsequently attenuated in a known manner.

The most important methods of X-ray technology

Digital radioscopy

In radioscopy, an X-ray source emits radiation which is able to penetrate objects. The radiation is attenuated depending on the material of the object (density, absorption) and the distance travelled inside the object, e.g. its wall thickness. On the opposite side of the source, a detector collects the incident radiation and generates a shadow image. With known material properties, the gray value of an image point in the shadow image is thus a measure of the wall thickness which the X-ray beam has penetrated on its way from the X-ray source to this pixel. Defects are characterized by a different absorption compared to the direct surroundings.

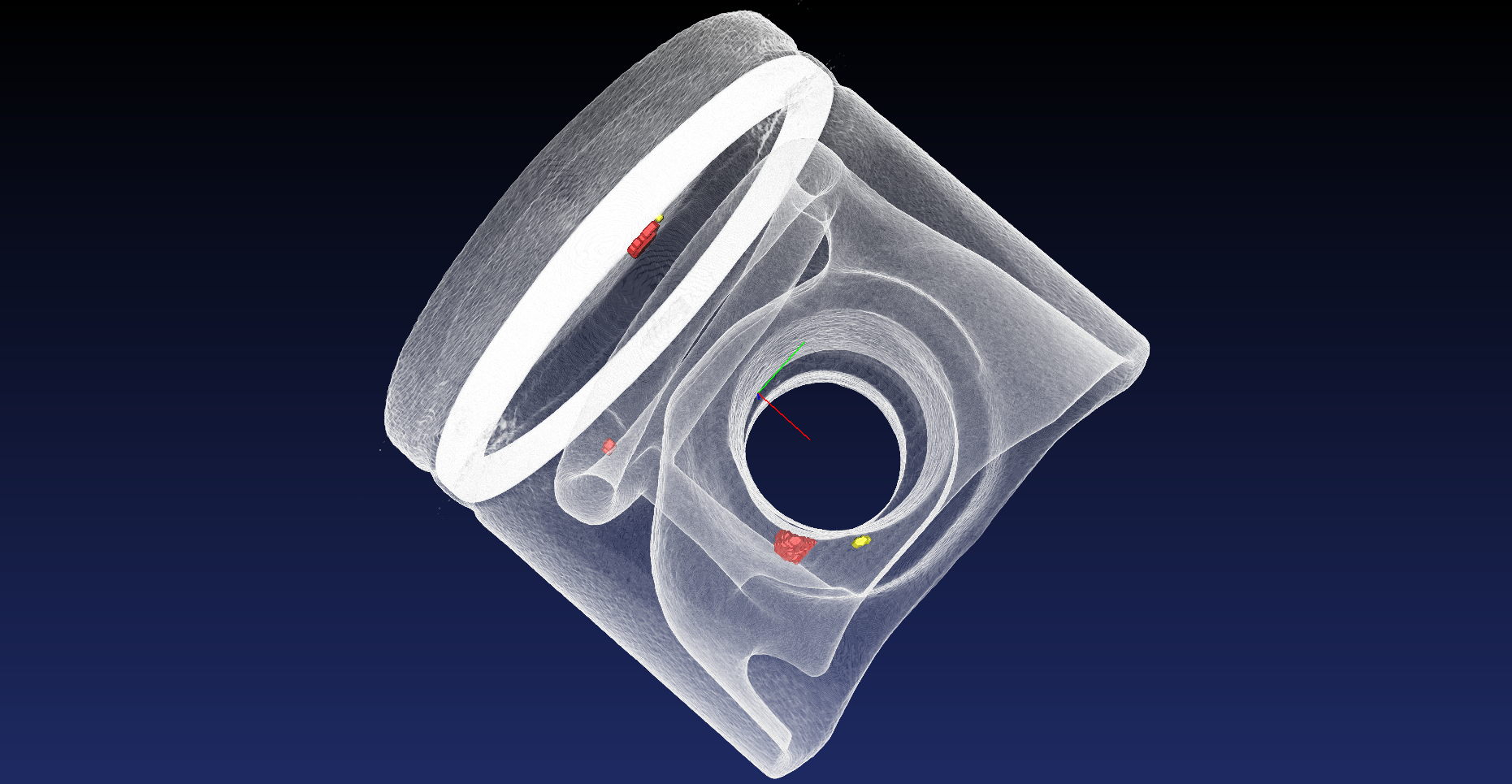

3D computed tomography

Opposed to radioscopy, 3D computed tomography generates several X-ray images of the same object from different directions, so-called projections. In contrast to CT devices in the medical field, the object is often fixed on a turntable in industrial CT systems and placed between the X-ray tube and the detector. The projections are recorded while the object rotates around its own axis. Viewed virtually, the tube and detector thus move on a circular path around the object.

(Computer) Laminography

If the objects to be tested are very large, firmly built into apparatus and/or not accessible from all sides, laminographic methods can be used. The basic principle of laminography is that the flat or permanently installed object is irradiated at different angles, but basically only from one side. Two of the three components X-ray tube, object and detector are moved in a coordinated manner.