Fraunhofer Vision Guideline Series - Volume 22

The Fraunhofer Business Unit Vision has published the 22nd volume of its guideline series. The »Guideline on Heat Flow Thermography« can be purchased for 39 euros, from the Fraunhofer Vision Webshop at shop.vision.fraunhofer.de or from bookshops. The 74-page publication presents the topic of heat flow thermography from the perspective of applied science and industrial research. The readers should get a realistic idea regarding the possibilities and the technologies available nowadays and learn about application methods and fields of application relevant for industrial practice.

Heat flow thermography

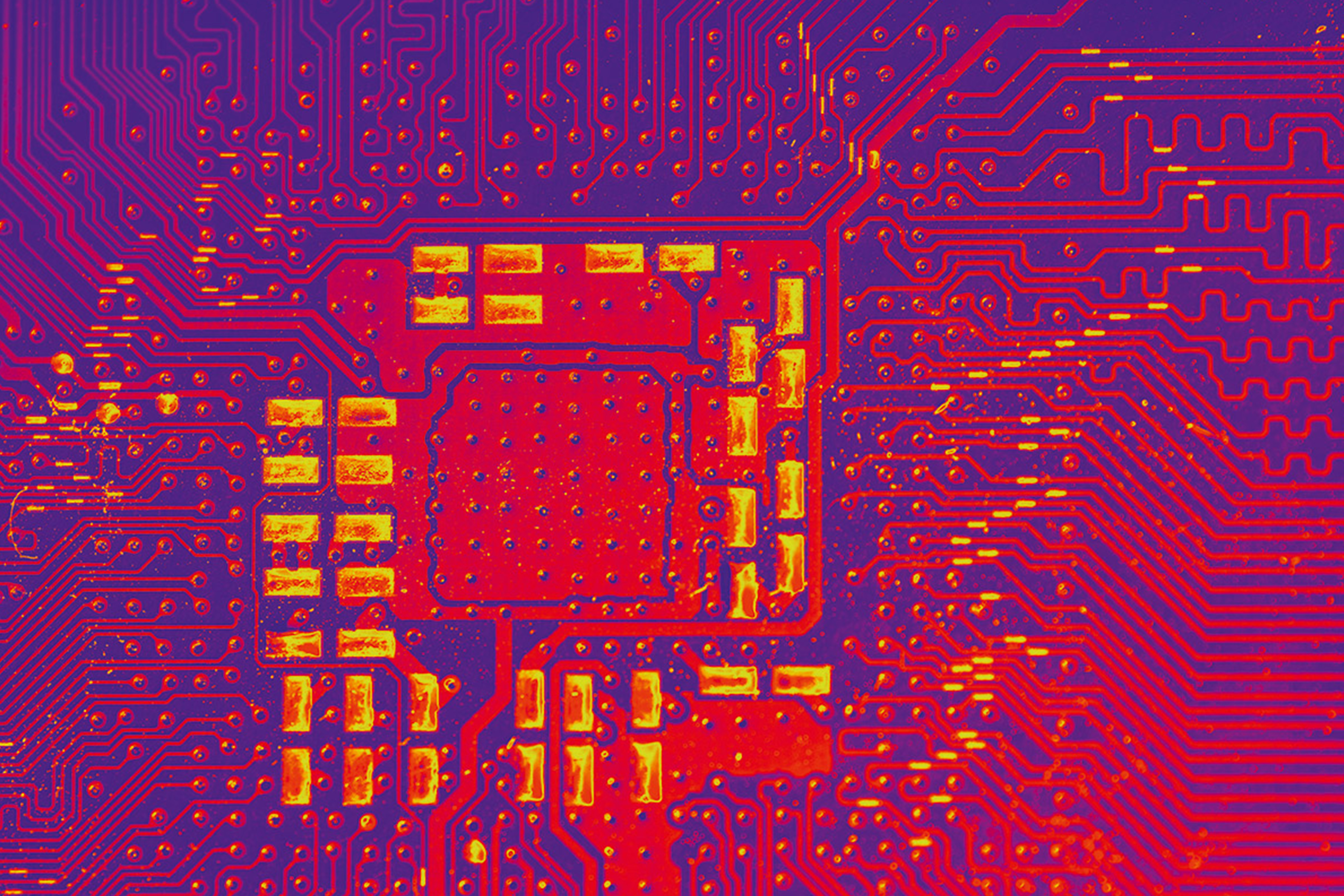

The importance of heat flow thermography as a non-destructive testing method for quality assurance in production continues to grow, because by analysing the heat flow or thermal conductivity it can be used to detect defects in workpieces lying below the surface and that are therefore not visible externally. Further advantages of thermographic heat flow testing are the imaging principle, the high testing speed and the relatively simple automation.

Motivation and content

Knowledge and understanding of the application possibilities, performance and limitations of modern measuring and inspection technology with image processing are an important prerequisite for the successful use of these systems and technologies in industrial manufacturing and quality assurance. The Fraunhofer Vision guideline series aims to contribute to this. Every year, one volume on a relevant topic from the field of image processing or non-destructive measuring and testing technology in which the respective state of the art is presented in a generally understandable and clear manner. The intention is to faciliate the acces for potential users. Now the »Guideline on Heat Flow Thermography« has been published as an updated new edition. It provides an overview of heat flux thermography, introducing typical procedures and methods as well as algorithms and camera technology. Subsequently, the practical range of applications, especially for quality assurance in manufacturing, is described based on realized applications, also taking into account current activities in the field of standardization.