The Special Show »Non-Contact Measurement Technology« at the international trade fair for quality assurance »Control« in Stuttgart, May 6th to 9th, 2025, will be held for the 19th time this year and will present the latest developments and pioneering technologies from the field of non-contact measuring and testing technology. The Special Show has established itself as a marketplace of innovations for both exhibitors and trade fair visitors and will be on display at booth 7401 in a centrally located position in hall 7 this year.

Exhibits of the 19th Special Show »Non-Contact Measurement Technology«

Concepts and goals

The Special Show, whose concept it is to present a variety of different technologies for non-contact and non-destructive measuring and testing technology in a concentrated area, offers interested parties and potential users initial guidance when selecting a suitable technology in order to master their own testing tasks. This is because the performance and flexibility of modern systems is constantly growing. Wider and wider scales are being covered and new fields of application explored. Due to the rapid pace of technical development, it is not easy for users to orient themselves on the market and make a suitable selection with regard to their own requirements.

In addition to this initial orientation aid, the exhibitors at the Special Show booth also offer complete non-contact measuring and testing systems, where visitors with specific tasks can find possible solutions.

The Special Show is being organized with the support of the Fraunhofer Business Unit Vision and P. E. Schall GmbH & Co. KG.

Topics and exhibits

Image processing cameras and components for flexible industrial applications

LUCID Vision Labs GmbH from Ilsfeld is presenting various camera technologies, including the »Triton2 EVS Event-Based Camera« and the new »Phoenix GigE Vision Camera Modules«.

The event-based »Triton2 EVS Event-Based 2.5GigE Camera« is equipped with the IMX636/637 image sensors from Sony and the Metavision® Intelligence Suite from PROPHESEE. The system can be used flexibly for a wide range of image processing applications such as motion analysis or vibration monitoring.

The »Phoenix GigE PoE camera modules« have a compact design with dimensions of 24 mm x 24 mm and 28 mm x 28 mm and have been specially developed for OEM integration. Thanks to the modular design with various lens mounts, housing orientations and Ethernet interfaces, the modules can be adapted for a wide variety of tasks.

Exhibitor: LUCID Vision Labs GmbH, Ilsfeld (Germany)

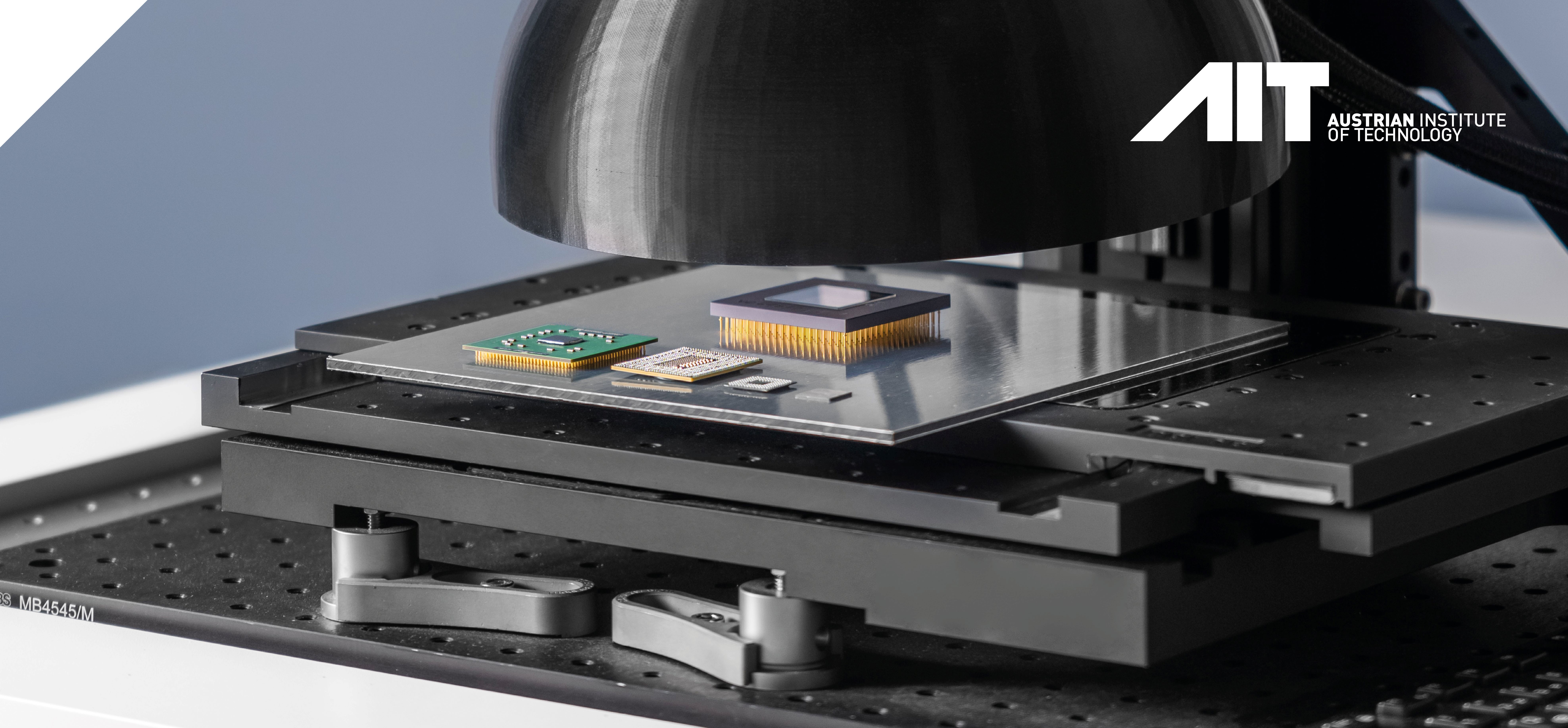

Inline 3D microscopy for precise and fast inspection of the smallest structures

The AIT Austrian Institute of Technology in Vienna presents »ici:microscopy«, a system for simultaneous microscopic 2D and 3D quality control. The inline 3D microscope delivers up to 40 million 3D points per second and therefore also enables large areas to be scanned quickly. It is suitable for inspecting the smallest structures even at high speeds and is based on the »Inline Computational Imaging (ICI)« technology developed at AIT. This combines the methods of light-field and photometry by using the natural transport movement of the object for simultaneous detection under different viewing and illumination directions. Possible areas of application include electronics production, the inspection of metallic surfaces and packaging and security printing.

Exhibitor: AIT Austrian Institute of Technology GmbH, Vienna (Austria)

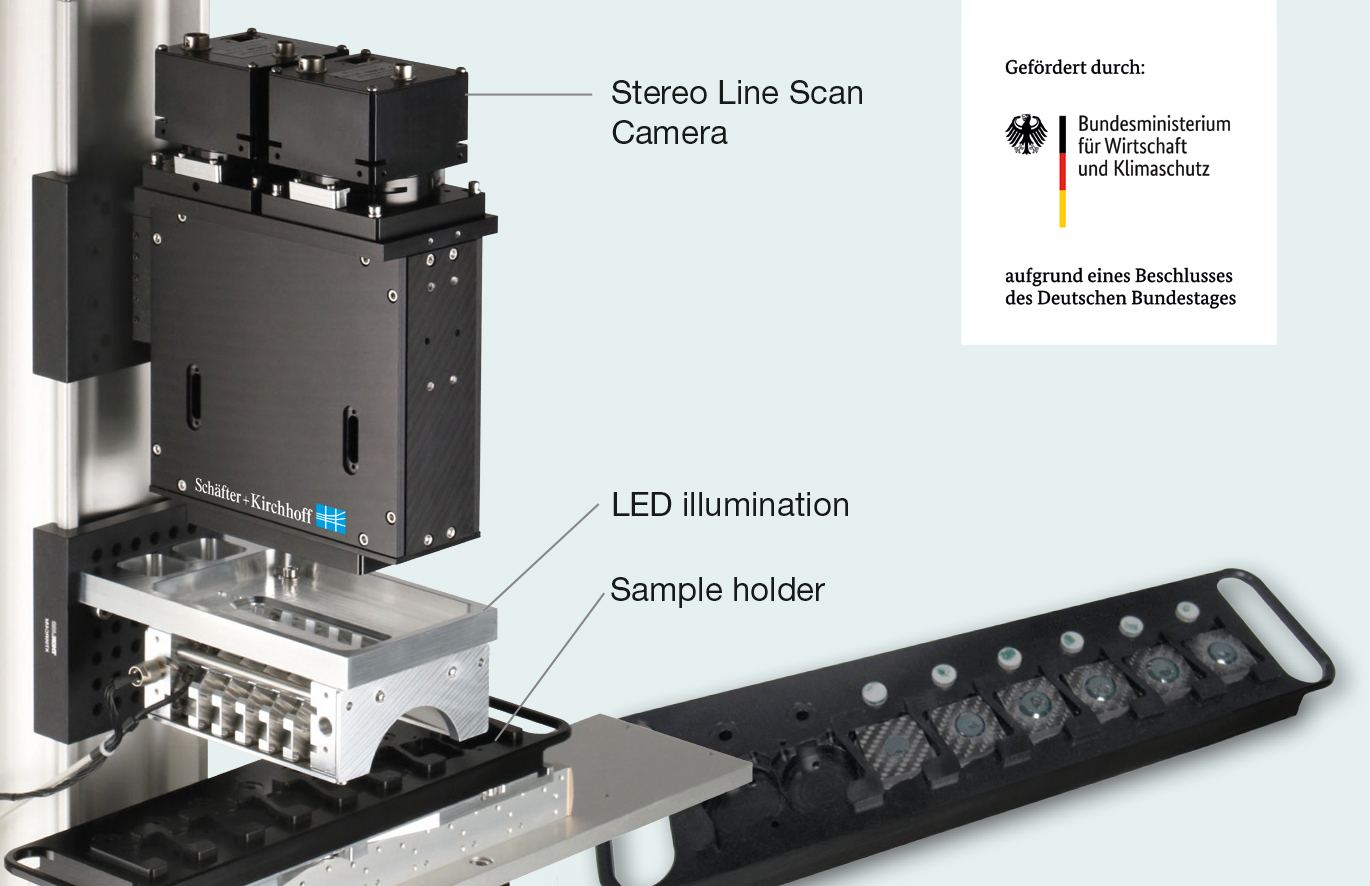

Surface inspection system for the examination of adhesive fracture surfaces

The »AdheScan system« from Schäfter+Kirchhoff GmbH in Hamburg is a complete system for quantifiable and reproducible adhesive fracture surface inspection. The technology provides an optical resolution of 11 μm, 3D height information with a resolution of 20 μm and a rotatable 3D display of each fracture pair. The user can annotate the sample in the view where it is easiest to identify the different fracture patterns. Possible applications include aerospace, lightweight construction and the automotive industry.

Exhibitor: Schäfter+Kirchhoff GmbH, Hamburg (Germany)

Innovative image processing components for a wide range of applications

OPT Machine Vision GmbH, based in Leinfelden-Echterdingen, is presenting a selection of new image processing components for a wide range of applications. The cameras, sensors, lenses, and lighting technologies presented are available as standard components, but can also be customized to meet specific customer requirements.

Exhibitor: OPT Machine Vision GmbH, Leinfelden-Echterdingen (Germany)

High-resolution microfocus X-ray tubes and X-ray technology for reliable, fast and precise inspection of objects

Viscom SE from Hannover is presenting various microfocus X-ray tubes from the »X9000 Series«, which were specially developed for industrial inspection. With their broad power range and diverse design configurations, the series covers a wide range of applications. It includes direct-beam tubes with up to 320 kV and 640 W, as well as transmission tubes with up to 120 W target power. These configurations enable very fast inspection with high image quality or, optionally, very high inspection quality for solid and large objects. These X-ray tubes are used – installed in proprietary X-ray inspection systems or as OEM components – in the electronics, automotive, medical, and battery industries, as well as in aerospace.

Exhibitor: Viscom SE, Hannover (Germany)

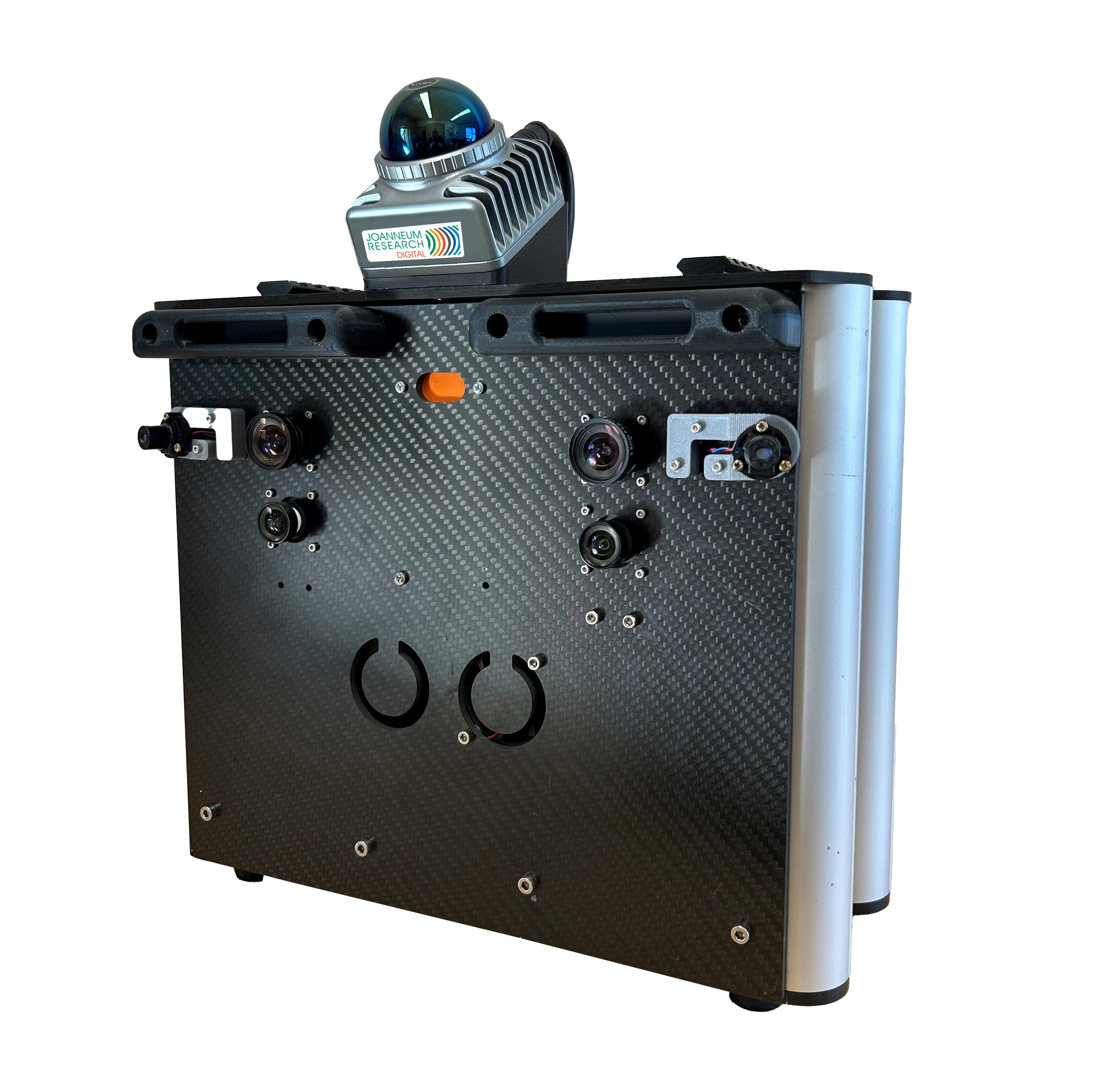

Precise real-time 3D acquisition of spatial data using LiDAR technology

JOANNEUM RESEARCH Forschungsgesellschaft mbH, DIGITAL – Intelligent Vision Applications, from Graz (Austria), is demonstrating a hybrid solid-state LiDAR sensor that, in combination with SLAM (Simultaneous Localization and Mapping) methods, enables precise real-time 3D acquisition of spatial data. The technology captures detailed 3D information of environments, enabling precise modeling and mapping with minimal setup and computational effort. Furthermore, the quality of the data can be improved by integrating stereo information, enabling the creation of accurate 3D models. The technology not only enables efficiency increases in traditional industries such as construction, the timber industry or robotics, but also opens up new possibilities in design and virtual reality.

Exhibitor: JOANNEUM RESEARCH Forschungsgesellschaft mbH, DIGITAL – Intelligent Vision Applications, Graz (Austria)

Confocal 3D measuring systems for quality assurance of surfaces

twip optical solutions GmbH from Pleidelsheim is presenting various confocal 3D measuring systems for surface inspection. The mobile technology »CONSIGNO MR« can be flexibly adapted to a wide range of measuring tasks and is operated via touchscreen. Thanks to its compact design and integrated battery supply, it is possible to carry out roughness measurements regardless of location. After the measurement, the results can be displayed directly or exported using a measurement report via the integrated USB slot.

The fast optical measuring device »CONSIGNO UL«, which specializes in roughness depth and contour measurement, will also be on show, enabling flexible use in quality assurance and production measuring technology. This system is characterized by its small and lightweight size and robust mechanical design. An innovative mechanical drive ensures a high measuring speed over the entire measuring range.

Exhibitor: twip optical solutions GmbH, Pleidelsheim (Germany)

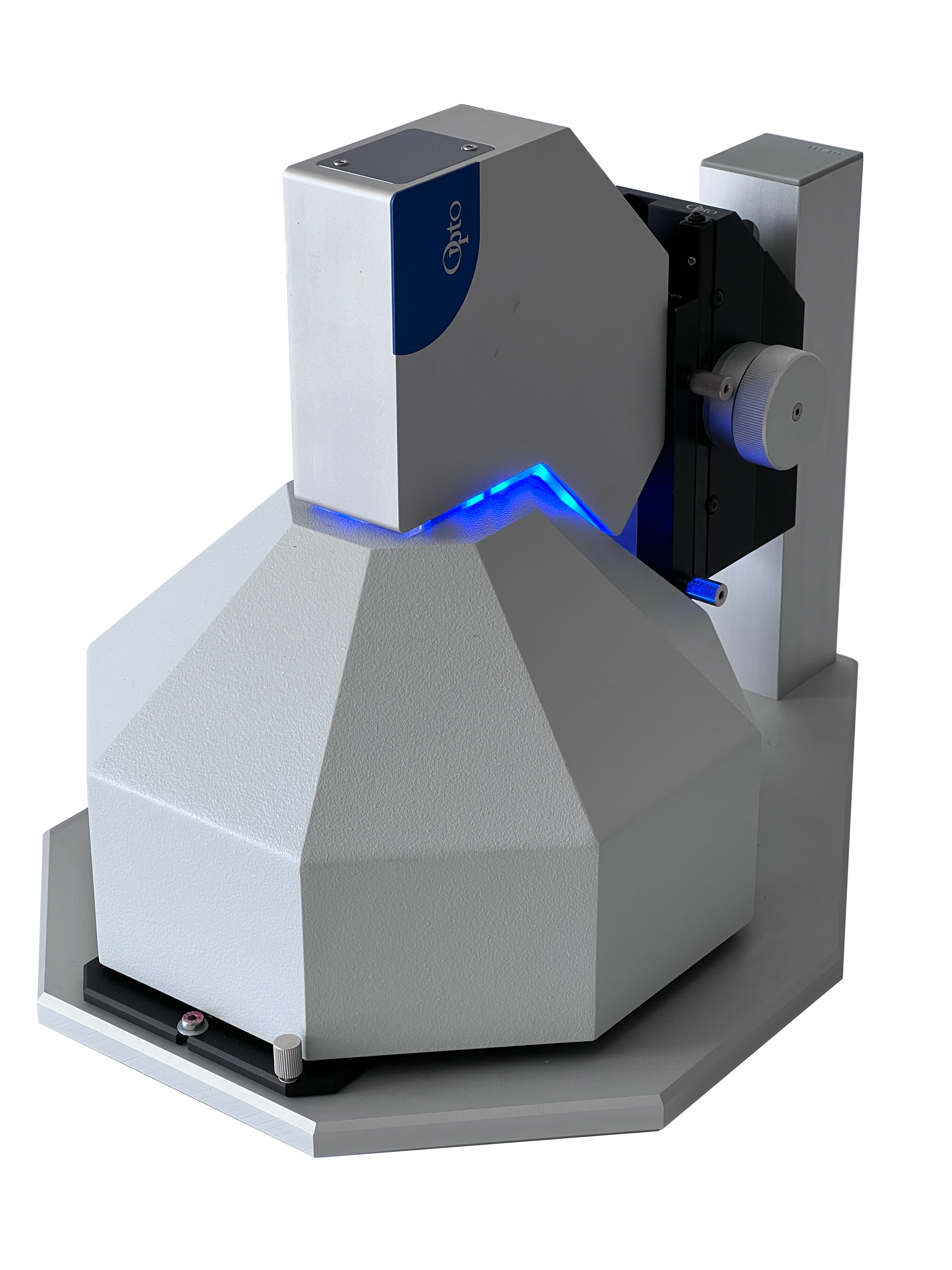

System for rapid anomaly detection on metallic surfaces

With »solino™«, Opto GmbH from Neuried near Munich is presenting a system for rapid anomaly detection on metallic surfaces. The technology combines photometric stereo imaging with the analysis of the resulting reflections for surface inspection. An algorithm compiles an optimized image from many individual images for further processing so that defects, scratches, edges or colour differences can be detected. The system creates a digital signature for each object point, which can increase the lateral resolution of a camera. This means that even the smallest defects can be reliably detected, even on large surfaces.

Exhibitor: Opto GmbH, Neuried (Germany)

Fully automatic inspection station for 2D and 3D inspection in small series production

Compar AG from Freienbach, Switzerland, is presenting an autonomous optical system for 2D and 3D inspection in small series production. The compact and flexible technology consists of a loading unit, a robot and an image processing system that not only generates the information for the robot unit for further handling, but also performs the quality checks. The system combines 2D and 3D inspections, OCV tests and deep learning algorithms to identify and classify parts and perform quality checks. Thanks to its modularity, it can be expanded at any time to include grippers, additional inspection stations or assembly functions. Possible applications include the watchmaking, packaging, medical technology, automotive and pharmaceutical industries.

Exhibitor: Compar AG, Freienbach (Switzerland)

Hyperspectral measuring system for fast and extensive inspection of surfaces and thin films

DIVE imaging systems GmbH from Radeberg presents the »VEpioneer®« a fully integrated measurement system for the fast and non-destructive inspection of components. Using this one-button desktop device, large-area measurements of surfaces (e.g., substrates such as metals, polymers, glass, semiconductors, or ceramics) and thin layers (e.g., oxides, nitrides, carbides, or polymers) are possible. It captures surface properties, contamination, and defects with an average measurement time of 20 seconds and is based on the principle of hyperspectral imaging (HSI). Possible applications include the inspection of bipolar plates, printed circuit boards, or wafer-based products.

Exhibitor: DIVE imaging systems GmbH, Radeberg (Germany)

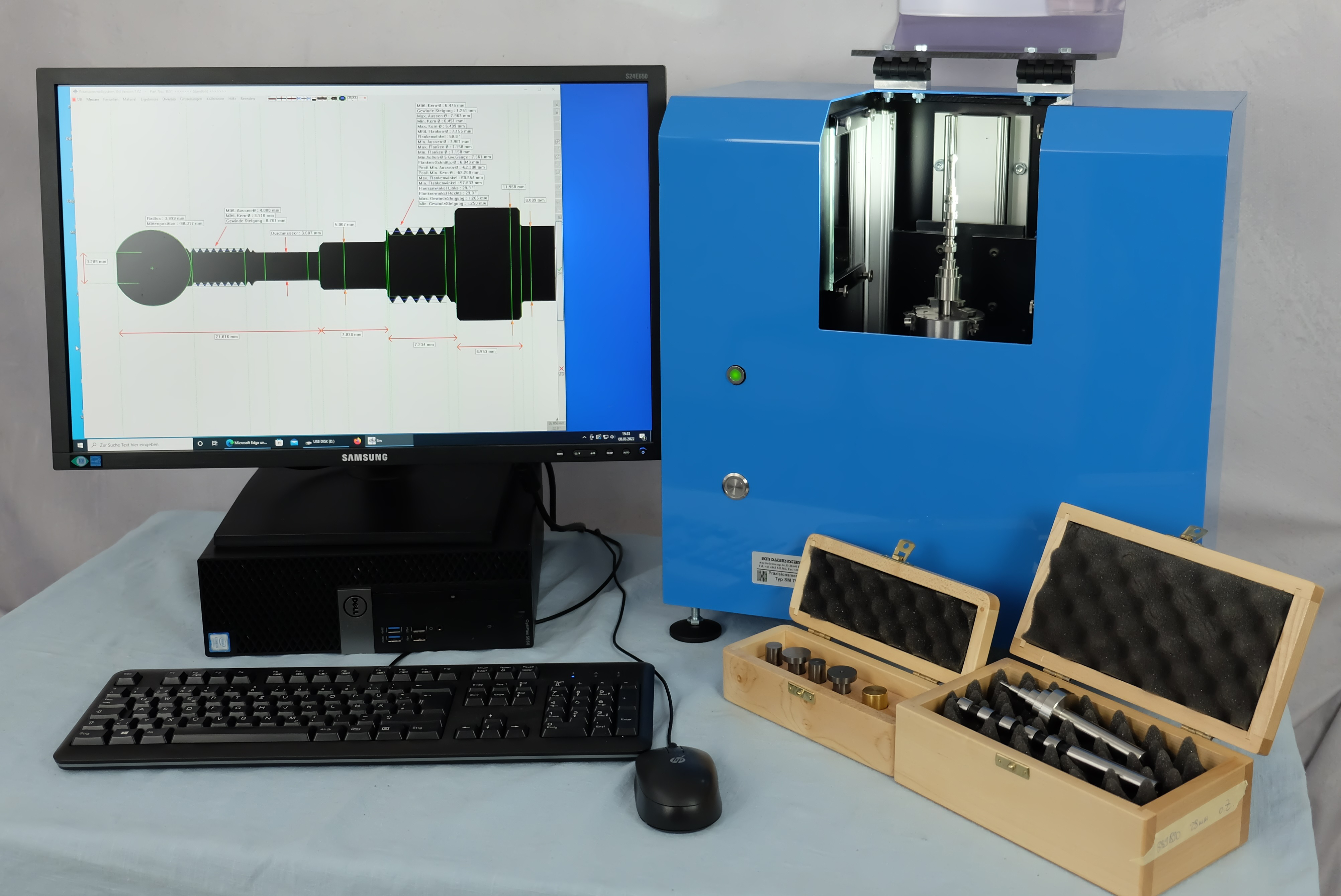

Precise optical measurement of dimensional, shape and position tolerances on rotationally symmetrical components

The Institut für Umformtechnik der mittelständischen Wirtschaft GmbH from Lüdenscheid, in cooperation with ECM Datensysteme GmbH from Bliedersdorf, presents a fast optical precision measuring system for the automated measurement of dimensional, form and position tolerances on rotationally symmetrical components.

The system works on the basis of the shadow image method, delivers comprehensive measurements in the micrometer range within seconds and has been specially developed for use in the manufacturing sector. It is used both for random sample testing during production (factory self-inspection) and for initial sampling.

Exhibitor: Institut für Umformtechnik der mittelständischen Wirtschaft GmbH, Lüdenscheid (Germany)

Test head for detecting defects in weld seams using laser thermography

edevis GmbH from Leinfelden-Echterdingen is presenting a laser testing head for detecting defects in weld seams made of various materials (e.g. aluminum, steel or copper) and cell connectors up to 1 mm. The system is based on the principle of heat flow thermography. A laser is used to briefly heat a test sample in a non-destructive manner. Phase images make the heat flow in the test area visible and provide information about structural changes that may be hidden beneath the surface. This is because the correlation between heating and cooling makes it possible to determine whether a cell connection is defective.

Exhibitor: edevis GmbH, Leinfelden-Echterdingen (Germany)

Real-time measurement of small components with GigE industrial cameras

»The Imaging Source Europe GmbH« from Bremen is presenting a wide range of image processing components for a variety of applications in automation and quality control. With the 8 megapixel monochrome GigE camera »DMK 33GX545«, for example, precise dimensional measurements can be carried out on small industrial components. The camera is designed to inspect fast-moving components and delivers reliable results even under difficult production conditions. Possible areas of application include automated assembly lines, quality control stations and complex manufacturing processes that require high precision. Other technologies presented allow real-time inspection systems to be integrated directly into the production line or have an integrated motorized lens for software-controlled adjustment of focal length, aperture and focus, which are used primarily in tasks with variable working distances, object sizes and lighting conditions.

Exhibitor: The Imaging Source Europe GmbH, Bremen (Germany)

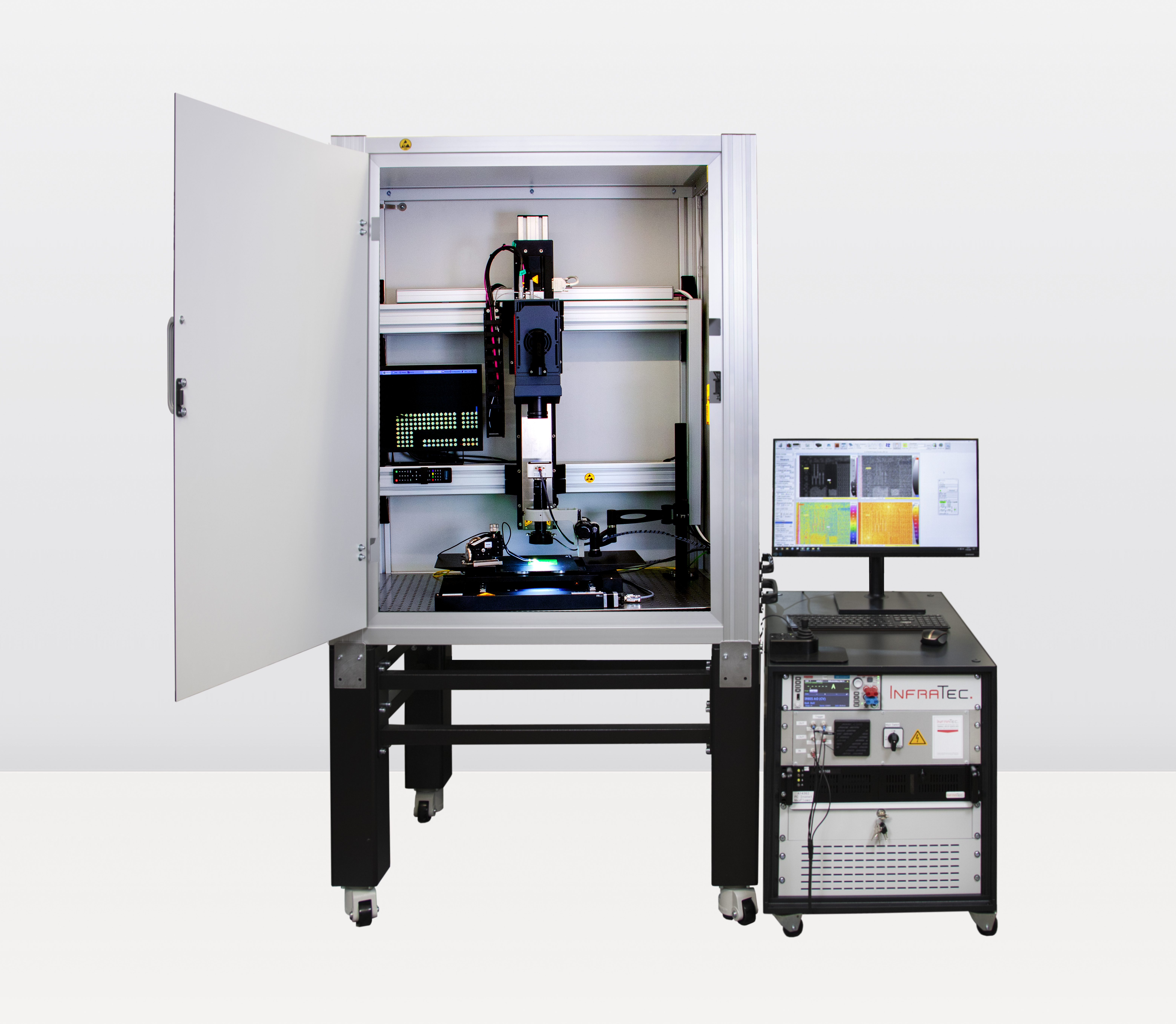

Thermography system for non-destructive electronics and semiconductor module testing

InfraTec GmbH Infrarotsensorik und Messtechnik from Dresden is presenting the »E-LIT« thermography inspection system, an automated solution for the non-contact defect inspection of semiconductor materials as well as electronic components and circuits. The modular system can be used both early during development and later during ongoing production and uses methods of lock-in thermography with electrical stimulation. This allows a wide variety of defects to be precisely detected and localized, such as point and line short-circuits or handling, manufacturing and oxidation defects.

Exhibitor: InfraTec GmbH Infrarotsensorik und Messtechnik, Dresden

High-speed image processing for industrial quality assurance

Emergent Vision Technologies, Inc. from Vancouver (Canada) is showcasing various high-speed cameras that can be used reliably with high resolution even in high-volume production environments. The »EROS 10GigE camera« is characterized above all by its small size of 29 mm x 29 mm and its low power consumption (from 3 W), while the new »16K TDI Line-Scan-Camera« can operate with high resolution (16,384 pixels per line) and at a speed of up to 1 MHz line rate. Typical fields of application can be found in semiconductor production, printing and web inspection.

Exhibitor: Emergent Vision Technologies, Inc., Vancouver (Canada)

Diverse camera protective housings for a wide range of applications

autoVimation GmbH from Rheinstetten will be presenting various camera housings for industrial environments that can be used in hot, cold, dirty conditions, or where special hygiene requirements are required.

Accessories include various viewing windows, wind curtains, protective flaps and the Meganova LED ring light. This LED lighting for camera housings with good heat dissipation allows the LEDs to be pulsed at 4x the brightness thanks to the built-in flash controller. The trigger behavior, gain and flash duration are programmable up to the limit of the stored LED characteristic curve, allowing a pulse-pause ratio of up to 1:1 to be achieved. The system's performance will be demonstrated with sharp images captured by a fan rotating at 50 km/h.

Exhibitor: autoVimation GmbH, Rheinstetten (Germany)

Practice-oriented knowledge on the use of industrial image processing

Image processing and non-contact measurement technology are used successfully today across all stages of the industrial value chain. Innovative technologies are an important element in the implementation of zero-defect concepts, aiming for 100% inspection in production, and support the development and qualification of new products. However, it is still not easy for potential users to decide which image processing technology is most suitable for their own applications. The on-site practical seminars, video seminars, technology days and publications from the Fraunhofer Business Unit Vision offer a decision-making aid for this.

Exhibitor: Fraunhofer Business Unit Vision, Fürth (Germany)