Ensuring quality without losing time: Companies from the pharmaceutical, chemical and food industry depend on meeting the highest quality requirements while at the same time optimizing production processes. For such applications, the Fraunhofer Institute for Applied Solid State Physics IAF, Freiburg, has developed in collaboration with the Fraunhofer Centre for Applied Photonics CAP in Glasgow (UK) an integrable measurement system.

With the inline-capable, laser-based infrared spectroscopy measurement system industrial companies from the pharmaceutical, chemical and food industry are supported in making quality assurance measures and process controls more reliable and at the same time more efficient. The system is characterized by a flexible design and a high spectral scanning speed that allows it to be integrated into existing visual inspection systems, enabling full spectroscopic inspection.

Mid-infrared backscattering spectroscopy by QCL and MOEMS grating scanner

The specific advantages of the system result from the backscattering spectroscopy method in the mid-infrared spectral range from 5 to 10 μm. Since molecular compounds have very characteristic absorption features in this spectral range, they can be clearly identified.

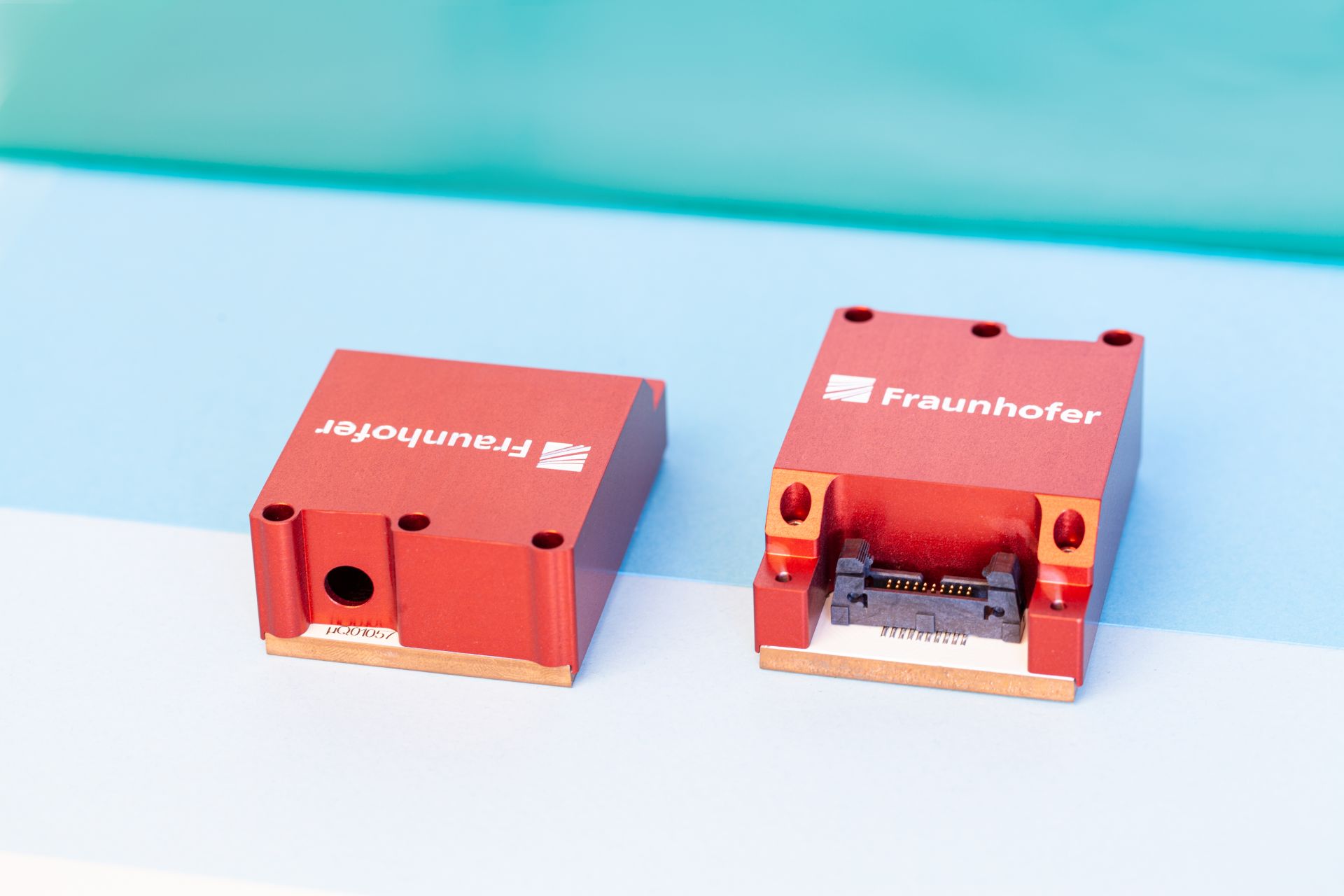

One of the core components of the measurement system is a broad-emitting and spectrally fast-scanning laser module. It combines quantum cascade lasers (QCLs) from Fraunhofer IAF and micro-opto-electro-mechanical grating scanners (MOEMS) from the Fraunhofer Institute for Photonic Microsystems IPMS in Dresden. The high brilliance of the light source and the unique properties of the MOEMS scanner enable infrared spectroscopy at a rate of 1 kHz. In the analysis of the measurement results, a neural network supports the system to drastically minimize the error rate and at the same time the required measurement time.

Demonstration of industrial use

In order to illustrate the measurement system’s ability to be integrated into industrial processes, a demonstration system has been built up: A conveyor belt moves twelve identical-looking tablets in a common tablet blister. The device recognizes the blister package as well as the position of the individual content and scans the blister content contactless in just 300 ms. The results of the detection for each individual tablet are immediately displayed on the connected screen so that contaminated or defectively loaded specimens can be sorted out.