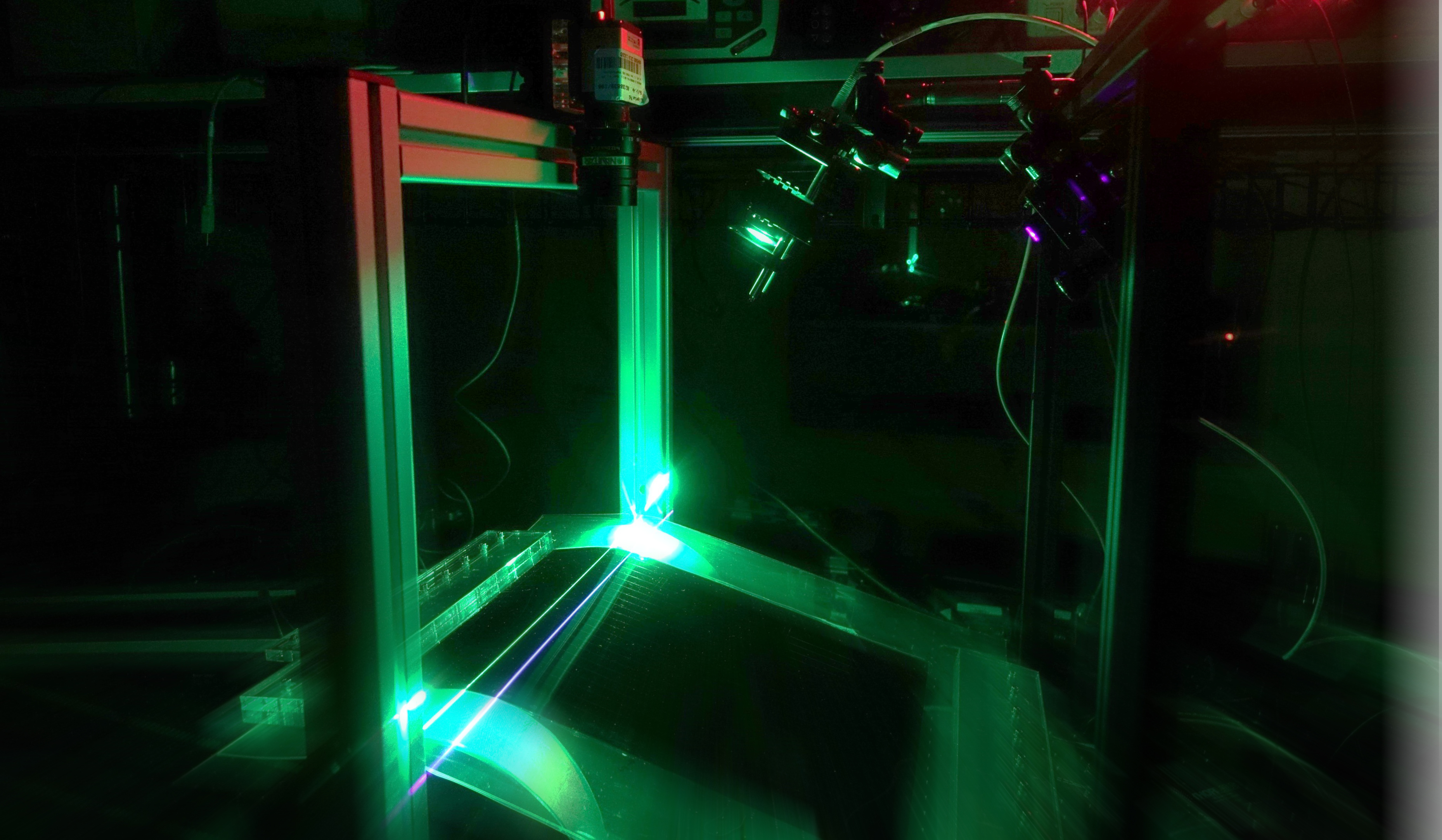

The Fraunhofer Application Center for Optical Metrology and Surface Technologies AZOM, a branch of the Fraunhofer IWS in Dresden, has developed an intelligent measurement system (SURFinpro) for AI-supported detection of surface features in roll-to-roll processes (R2R). During the manufacturing of various layer systems or film systems based on R2R technologies, defects typically occur during the manufacturing process, which affect the outer appearance of the layers or the general quality and functionality of the systems. The structure of such manufacturing defects can manifest itself in a wide range of different sizes and characteristics. A laser triangulation approach is instrumentalized for the detection of the defects. Depending on the process, the components used can be adapted for optimal detection of the imperfections.