Advanced hardware components and versatile software

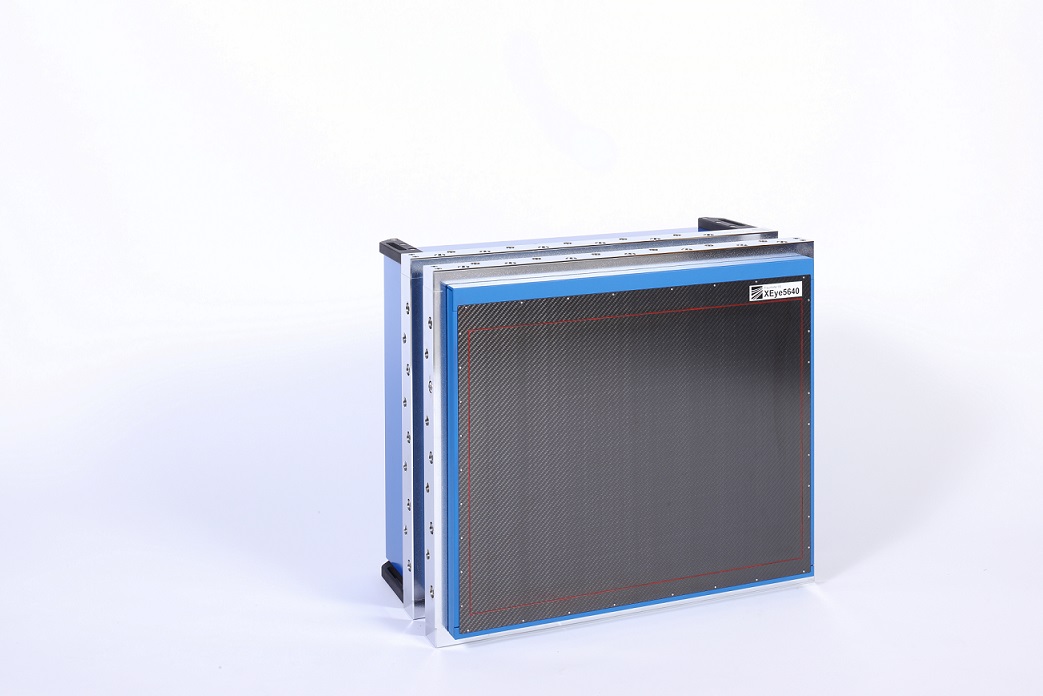

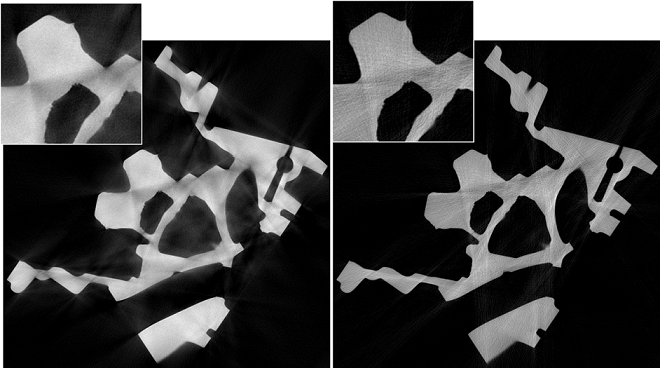

One of the most important components of an X-ray system is the X-ray detector used, as it largely determines the image quality. The radiation-stable X-ray cameras from the XEye series are suitable for a wide range of applications: The latest and largest detector, the XEye5640, has a significantly larger imaging area compared to other detectors, while at the same time offering very high radiation stability for up to 450 keV X-ray energy. The pixel size starting at 50 micrometers enables a more flexible and at the same time, a more efficient handling of test objects. Due to the detector area of 40 x 56 cm², large objects with high wall thicknesses, for example, for which several measurement runs were previously necessary, can be fully displayed or inspected with just one measurement. Application examples are the inline CT of clutch housings or the radiography of engine blocks within the production line in time with the manufacturing cycle. With the high-speed X-ray cameras XEye-HS of the XEye series, fast dynamic processes of hidden processes can be recorded. The imaging area, pixel size and maximum frame rate can be specifically adapted to the problem at hand, such as the observation of material deformations or turbulent flows.