Integration of process analytics into Industry 4.0 through open communication standard OPC-UA

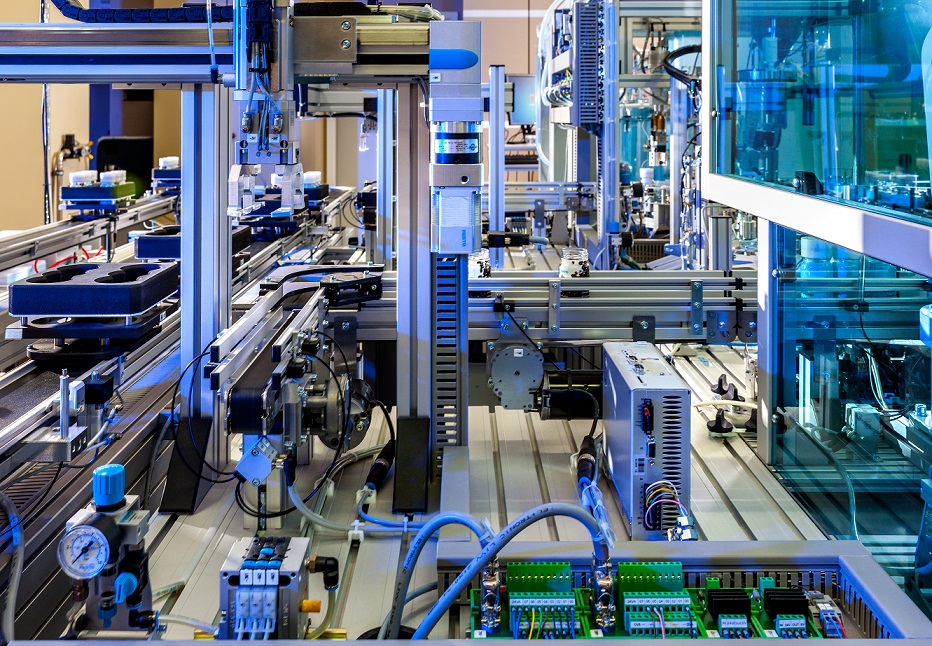

The SmartSpectrometer modules are integrated using the open communication interface OPC-UA (Open Platform Communications Unified Architecture), which ensures interoperable data and information exchange within and between different automation levels in the sense of Industry 4.0. Through the comprehensive collection and evaluation of spectroscopic measurement data and the exchange of production-relevant information, production processes can be optimised, quality increased and resources saved.

Data analysis at sensor level using embedded AI

The analysis of the spectroscopic measurement data is done by embedded AI (artificial intelligence) at the sensor level. A new method allows the migration of the calibration, which eliminates the complex and time-consuming development of the calibration models when replacing the sensors or when using several measuring points.

Cross-industry application possibilities

The areas of application for optical spectroscopy range from food production and agriculture (e.g. determining the degree of ripeness or monitoring plant health) to the chemical and pharmaceutical industries and the identification of plastics for recycling. In addition, the technology can also be used in hand-held analysis systems for »at-line measurements« in the production environment or incoming goods. Depending on the application and product, different spectral ranges come into question, which can be realised by the modular system approach through corresponding spectroscopic sensor modules, starting in the UV range up to the short-wave infrared range.