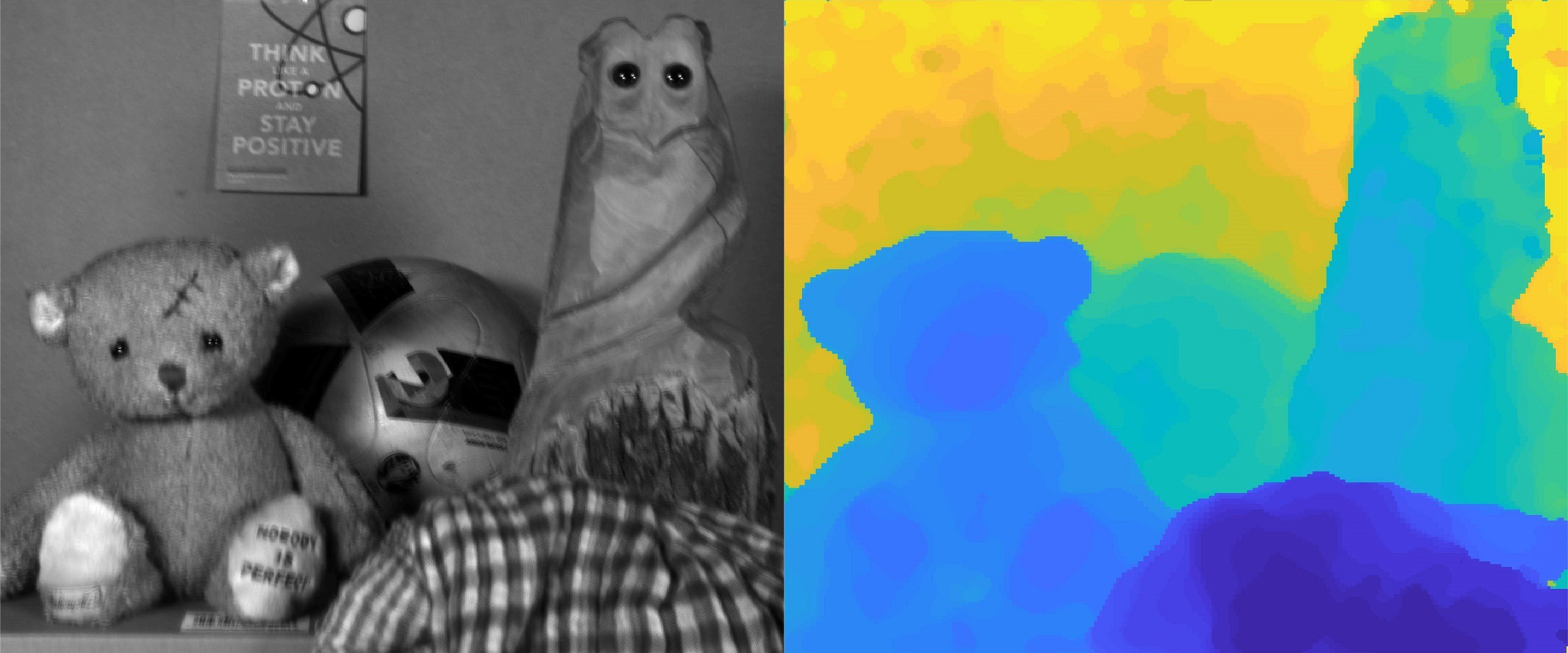

Fraunhofer IOF has developed a novel camera system for passive, optical 3D object detection. The acquisition principle is based on the integration of a micro-optical phase element within a conventional camera lens. The imaging properties of the lens are modified so that the 3D information of the object field is directly encoded in the captured raw image distribution. Adapted image post-processing can then be used to reconstruct the depth profile of the object on the one hand and the high-resolution lateral object distribution on the other. Possible applications range from human-machine interaction, quality control in manufacturing processes to the field of virtual and augmented reality.

In addition to the classic, two-dimensional image acquisition, the extended acquisition of depth information is the focus of current camera and sensor applications. Increasing demands in terms of 3D resolution, compactness and cost require innovative solutions, as existing concepts are pushed to their technological limits. Based on these demands, the camera system for passive, optical 3D object detection has been developed. In contrast to conventional stereo and multi-aperture arrangements, only one (monocular) camera is required. Thus, more compact and cost-efficient solutions can be implemented, which are superior to existing monocular and plenoptical concepts with respect to lateral and axial resolution.