Marketplace for innovations

The Special Show on »Non-Contact Measurement Technology« takes place at the Control 2023 for the 17th time presenting the latest developments and pioneering technologies in the field of contactless measuring and test technology.

The Special Show »Non-Contact Measurement Technology« at the Control fair has not only been an established industry meeting place for more than fifteen years but also a communication platform for exchange about developments and innovations in the field of contactless optical measuring and testing technology.

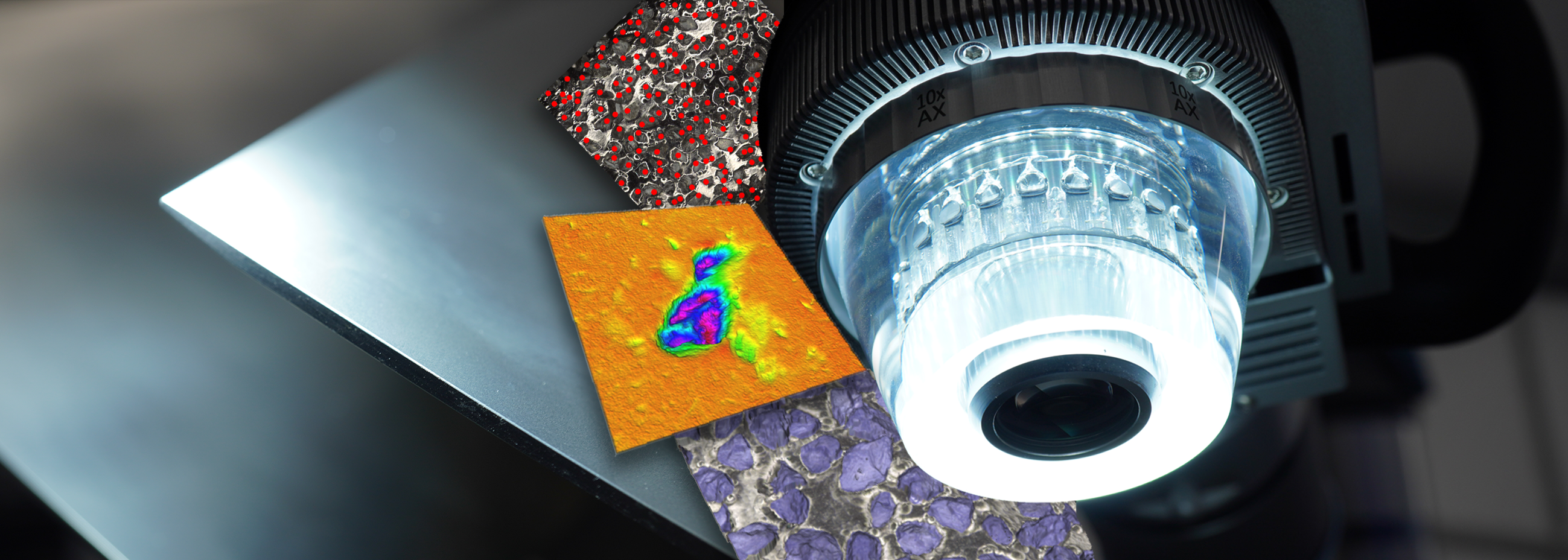

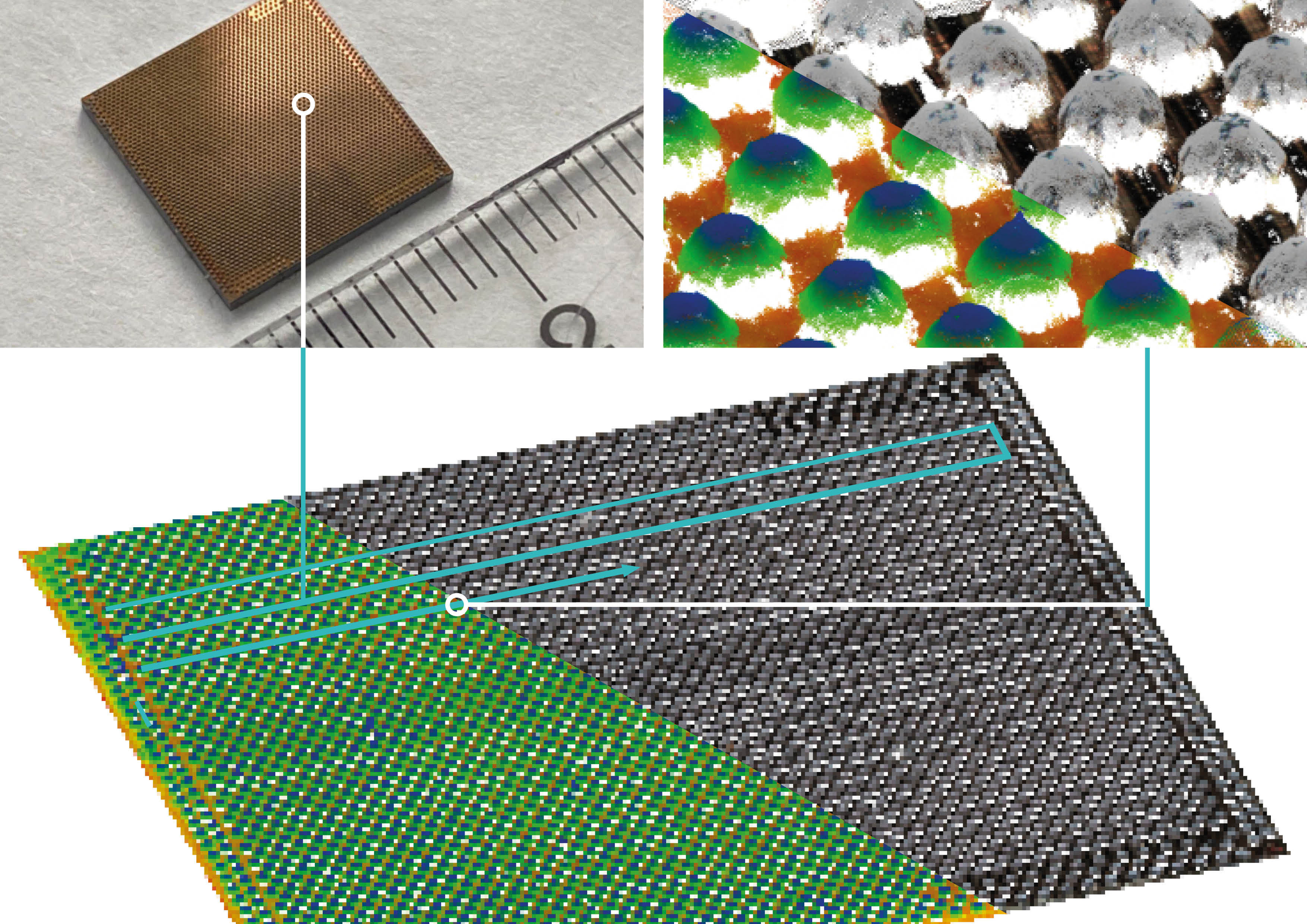

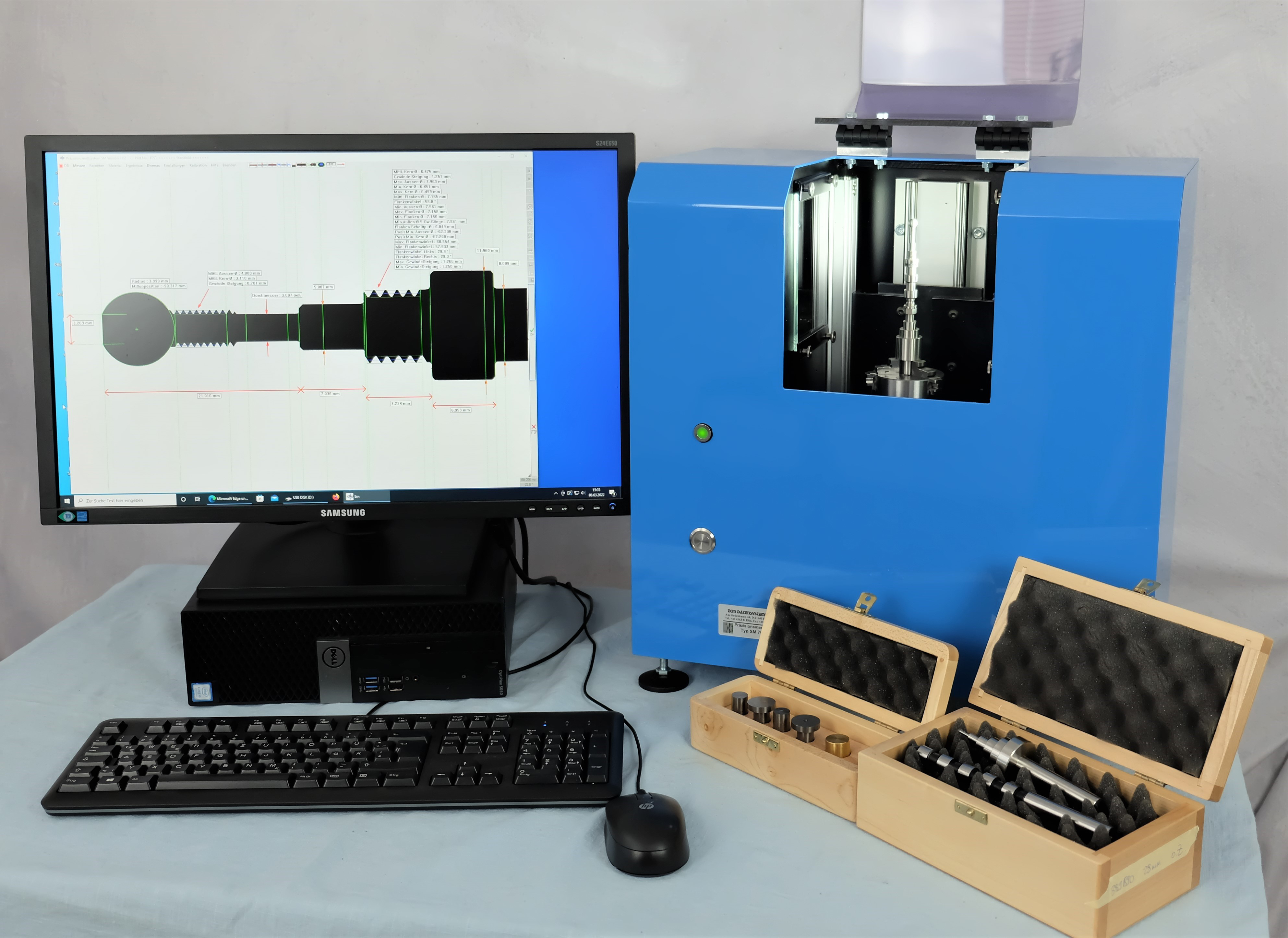

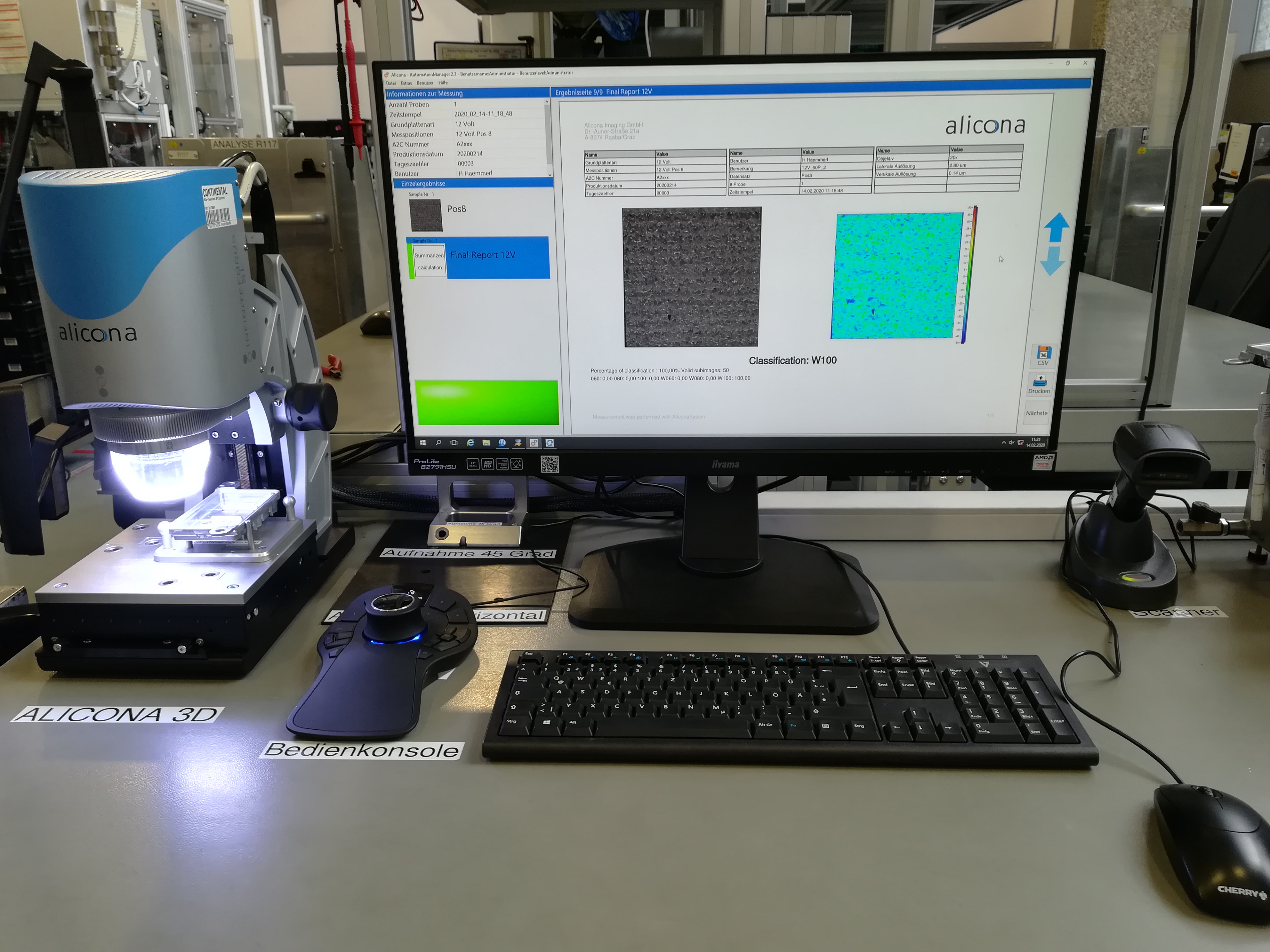

Thereby it contributes to increase the level of awareness as well as the acceptance of these technologies and to augment transparency in the offers. The visitors of the trade fair will be able to learn more about concrete applications of the performance of contactless measuring and testing technology. A wide range of innovative, non-contact technologies will be exhibited, such as light section, fringe projection, confocal measurement techniques, time of flight, etc. In addition to that, measurement and testing technologies for the interior of material such as thermography, computer tomography or ultrasound will be presented. Another focus will be on components like cameras and lenses, or x-ray tubes.