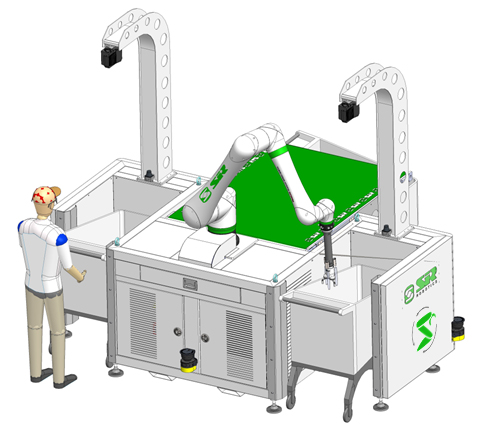

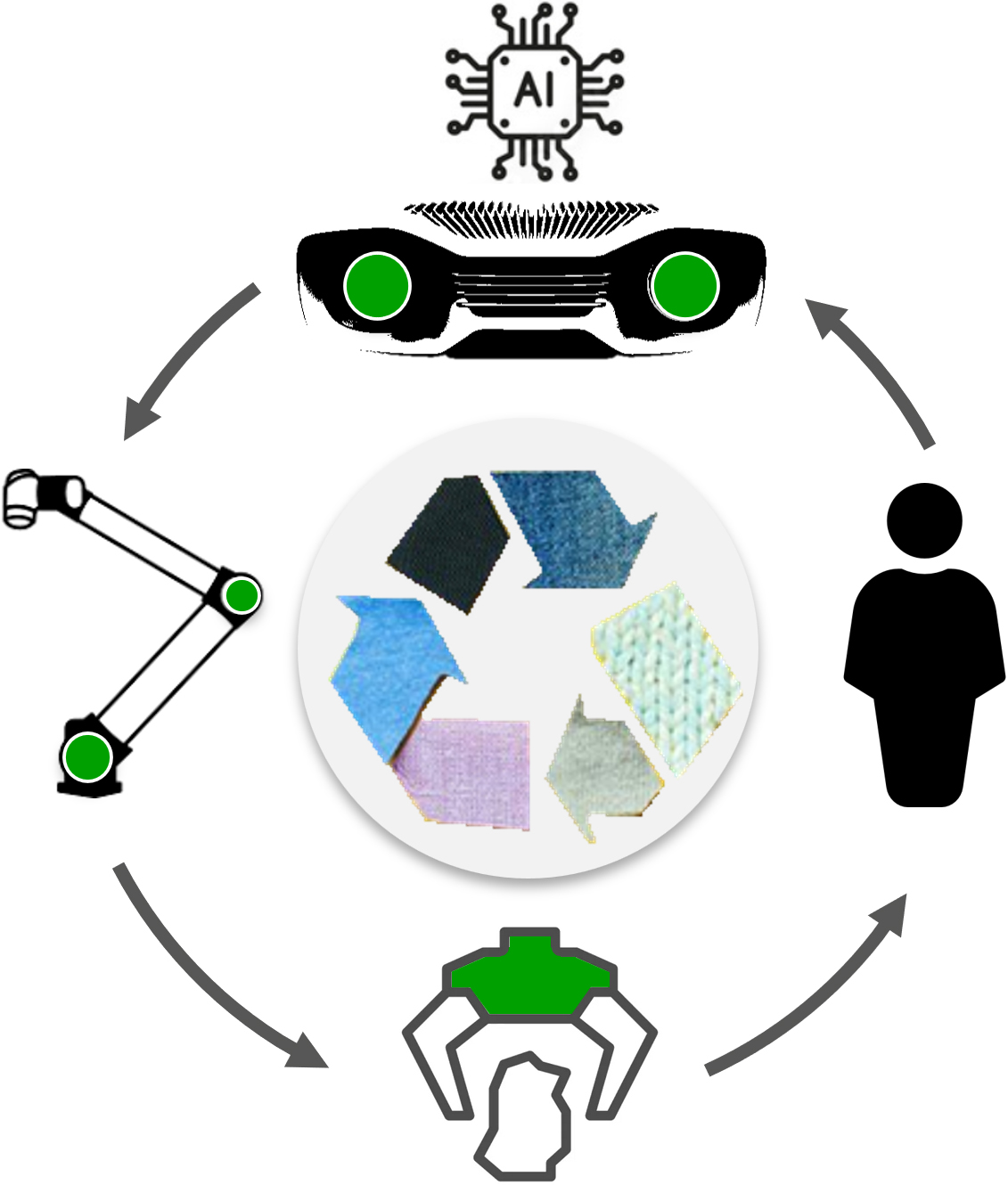

The Institute for Information and Communication Technologies DIGITAL of JOANNEUM RESEARCH Forschungsgesellschaft mbH from Graz (Austria) presents a demonstrator that shows the functional principle of the new »CoboSort« system for the automated sorting of randomly arranged fully packaged, partially packaged and unpackaged garments. The camera system, the recognition of the garments and the calculation of the optimum gripping position for separating the textiles will be on display. The proposed solution has a positive impact on the reuse of returned clothes on the fashion market and enables new business models with a smaller environmental footprint.

The core components of the complete system are a robot, a gripper, a sensor system and a special image processing system for analyzing the sensor data and the control logic, which is based on AI tools. A »Fanuc CRX-Cobot« with a customized gripper is used to ensure safety and acceptance in the work area. A »Zivid One Plus depth camera« is used for sensory input. Processing is based on a customized machine learning model and gripper control logic. Additional sensors provide continuous feedback on the »success« of the gripping. This forms the basis for continuous monitoring of the gripping quality and a constantly increasing gripping success rate by retraining and fine-tuning the involved machine learning models when required.