Genesi Elettronica SRL from Spilamberto (Italy) presents various programmable multispectral LED lighting systems which operate with up to 12 different wavelengths in the range from 400 nm to 1650 nm. The systems are designed for linear and matrix cameras and can control the different wavelengths both individually and simultaneously. This enables an optimum illumination configuration to make the defect or detail in question visible. The systems are used, for example, in analysis laboratories, in test machines to determine the optimum application-specific lighting or in production machines that analyze different workpieces on one single line.

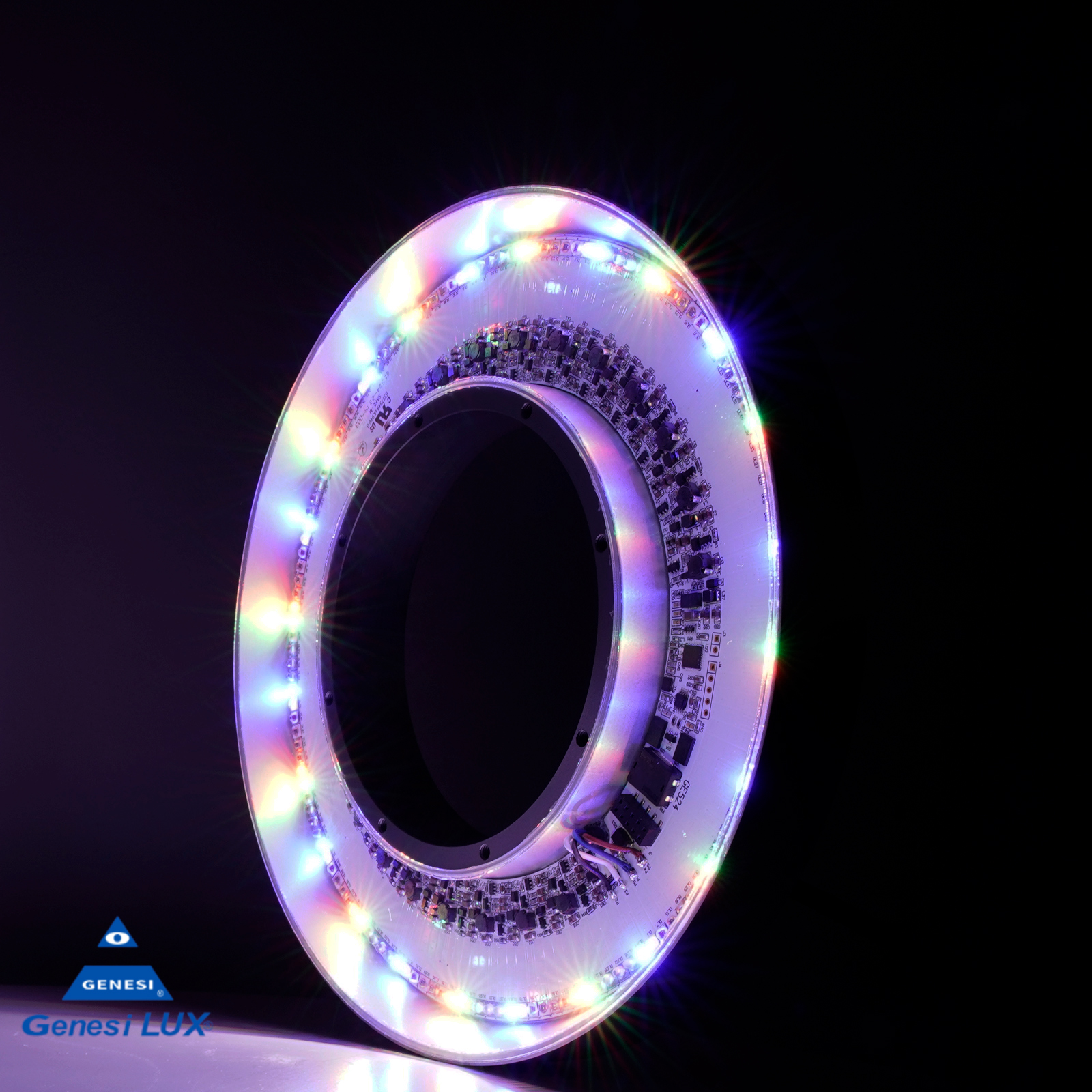

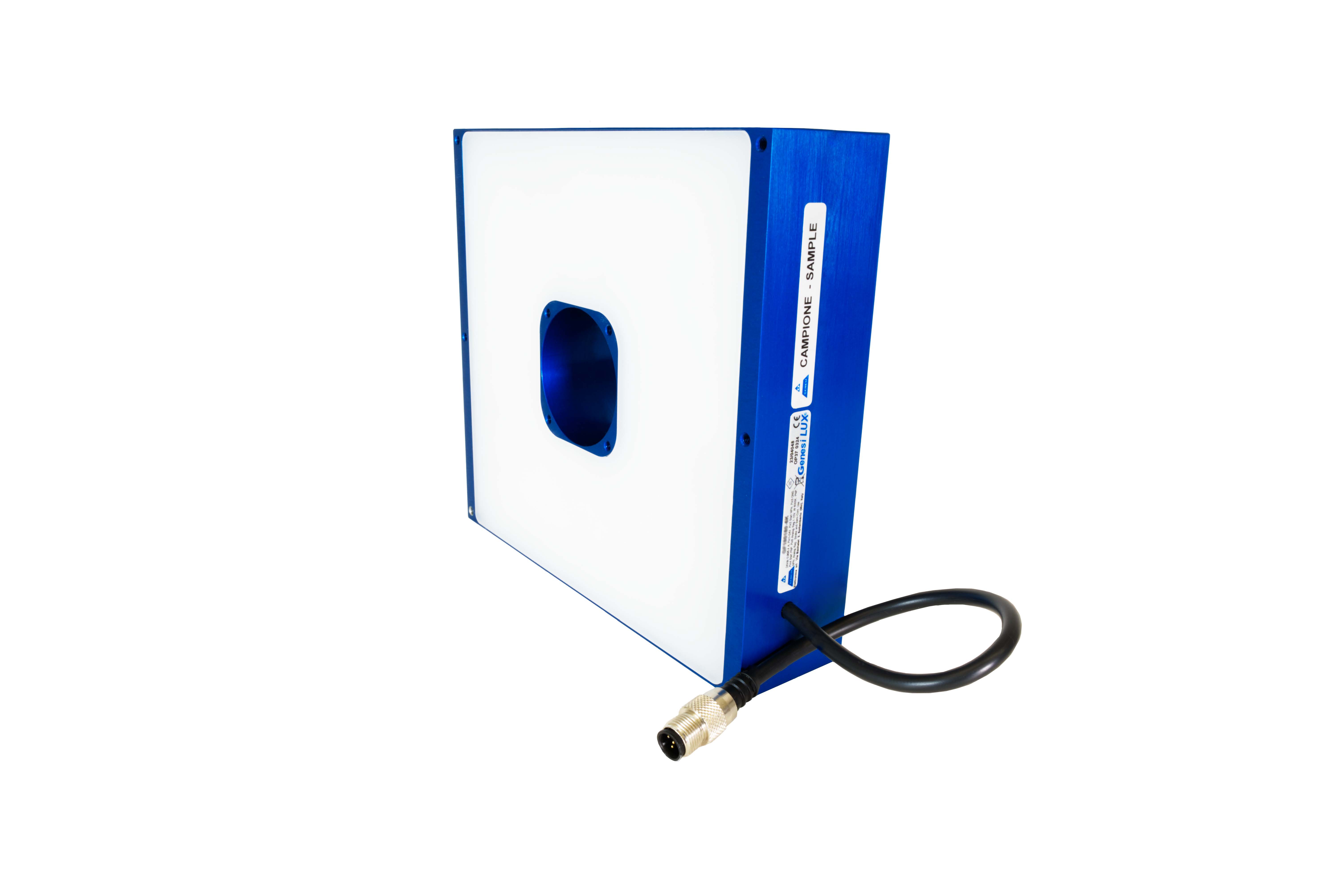

The presented product line consists of the bar light »GEVXD28-MS-400-1650« for linear and matrix cameras, the ring light »GEST220-MS-400-1650« for matrix cameras, the backlight »GB210280-MS-400-1650« and the flat dome »GF300300-MS-400-1650« for matrix cameras. All systems in this line are connected via RS485 and are supplied with a USB/485 converter and PC software with which the individual wavelengths can be switched on. The user can choose from 12 available wavelengths in the ultraviolet (UVA), visible light, near infrared (NIR) and short wave infrared (SWIR) ranges.