Speckle patterns have been used since the 1960s for the evaluation of quality-relevant material sizes and defects. In contrast to other speckle-based methods, the laser speckle photometry developed at the Fraunhofer Institute for Ceramic Technologies and Systems IKTS, Dresden, does not require a reference beam. This allows a simple and at the same time robust setup, which can be easily integrated into the process control technology. Measurement and calculation of the acquired data are performed in real time. The focus of research at Fraunhofer IKTS is currently on inline process monitoring for additive processes as well as coating and biotechnological processes. However, the test method is suitable for a variety of other applications.

The basis of laser speckle photometry is the evaluation of the temporal change of speckle patterns. A speckle pattern becomes visible when a rough surface is illuminated with a coherent light source. This produces a spatial structure with randomly distributed intensities that can be read out by means of a CMOS chip. If the examined object is also thermally or mechanically excited, the slightest changes in the speckle patterns can be used to draw conclusions about the properties of a wide variety of materials.

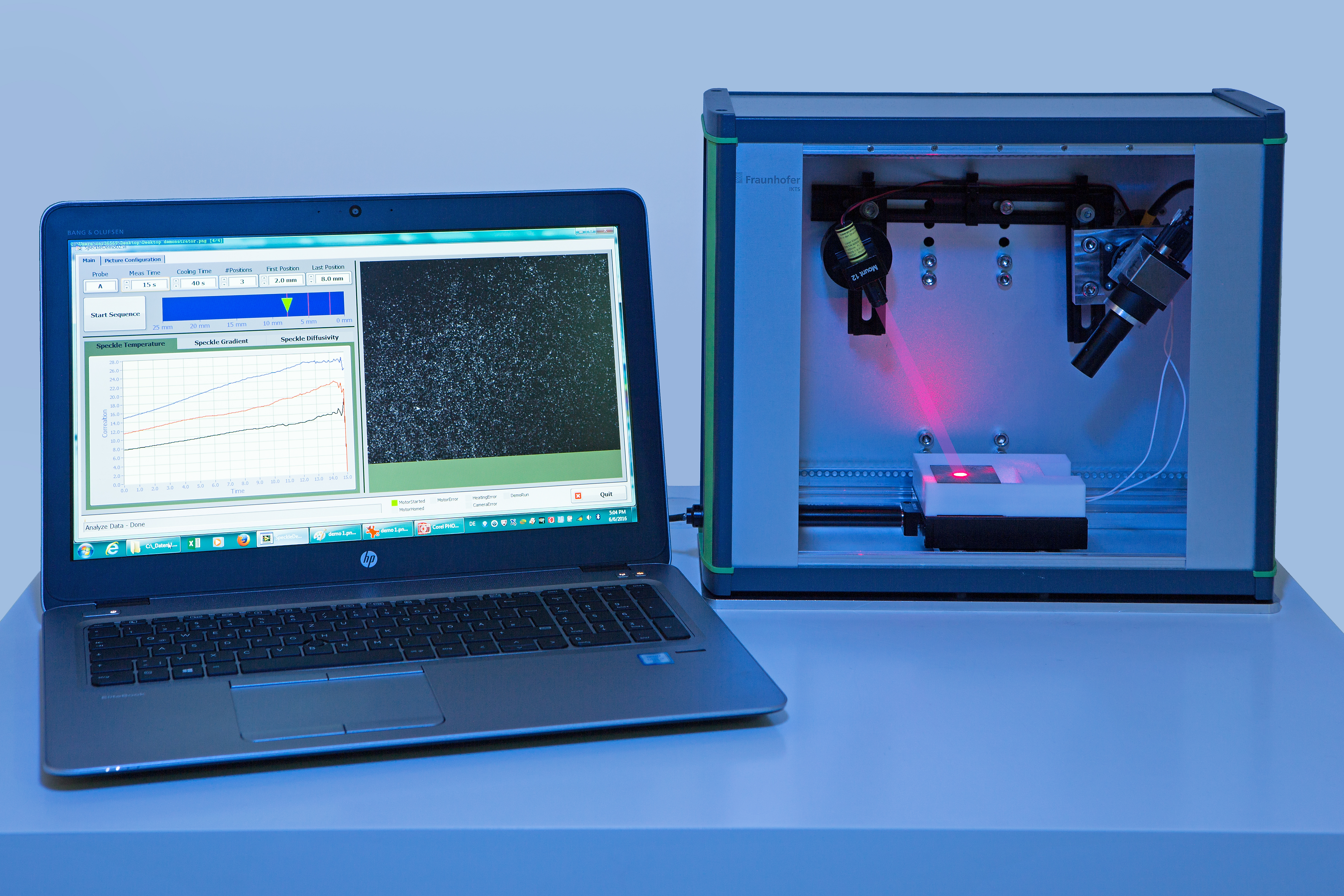

The LSP system presented consists of a sensor, electronics, hardware and software as well as the evaluation algorithm. Since it has a modular design, it can be adapted to a wide range of cases. In addition to roughness, material parameters can also be determined non-destructively. These include porosity and strain, or stress states on the surface or special process variables. It is now possible to detect surface defects in metallic materials smaller than 10 µm using special algorithms. In ceramics, this value is around 40 µm, and in fast roll-to-roll processes it is currently around 70 µm. The extremely short measuring times predestine the LSP method for inline use in industrial production, but also for in-situ measurements during maintenance and repair tasks.