In the context of Industry 4.0, more and more diverse inspection tasks are emerging, generating larger volumes of data that are often not easy to interpret. Artificial intelligence (AI) can assign meaning to these measured values and assess the overall situation. The Fraunhofer Institute for Ceramic Technologies and Systems IKTS in Dresden offers a comprehensive range of state-of-the-art artificial intelligence methods for the automatic evaluation of technical and non-technical processes.

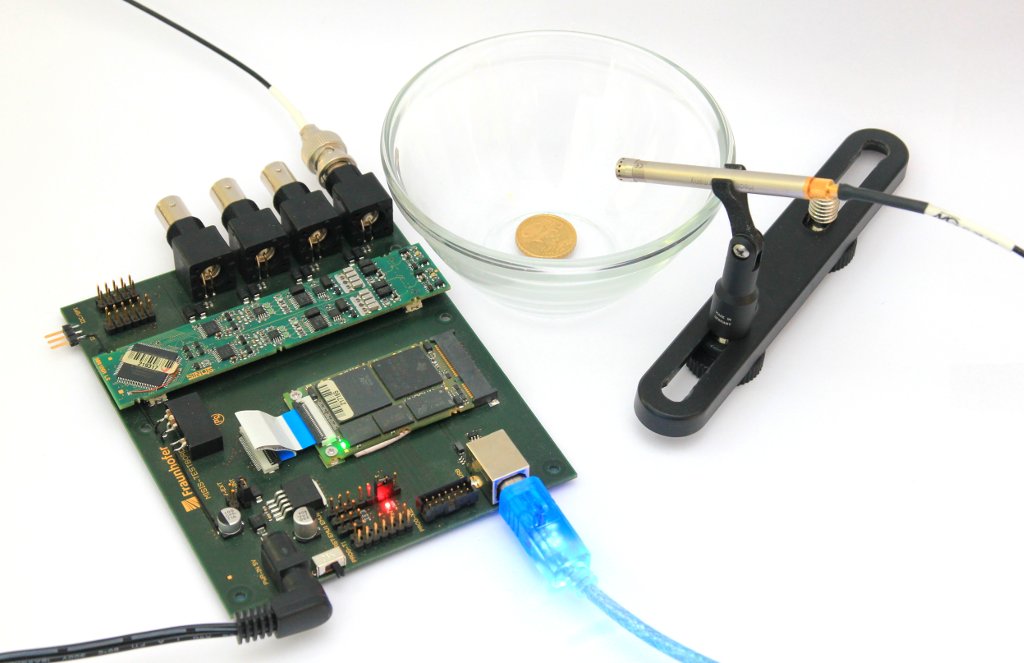

Acoustic diagnosis methods can be used to detect faults in manufacturing and operating processes with little effort. Defective components as well as critical plant and operating processes have specific noise patterns that are used for quality assurance.