autoVimation GmbH from Rheinstetten will be presenting various camera housings for industrial environments that can be used in hot, cold, dirty conditions, or where special hygiene requirements are required.

Accessories include various viewing windows, wind curtains, protective flaps, and the Meganova LED ring light. This LED lighting for camera housings with good heat dissipation allows the LEDs to be pulsed at 4x the brightness thanks to the built-in flash controller. The trigger behavior, gain and flash duration are programmable up to the limit of the stored LED characteristic curve, allowing a pulse-pause ratio of up to 1:1 to be achieved. The system's performance will be demonstrated with sharp images captured by a fan rotating at 50 km/h.

Diverse camera protective housings for a wide range of applications

Modular systems for image processing solutions

Sample installations based on the »Machine Vision Building Kit« and its counterpart in hygienic design show how machine vision components can be flexibly installed and positioned in different manufacturing environments using modular components.

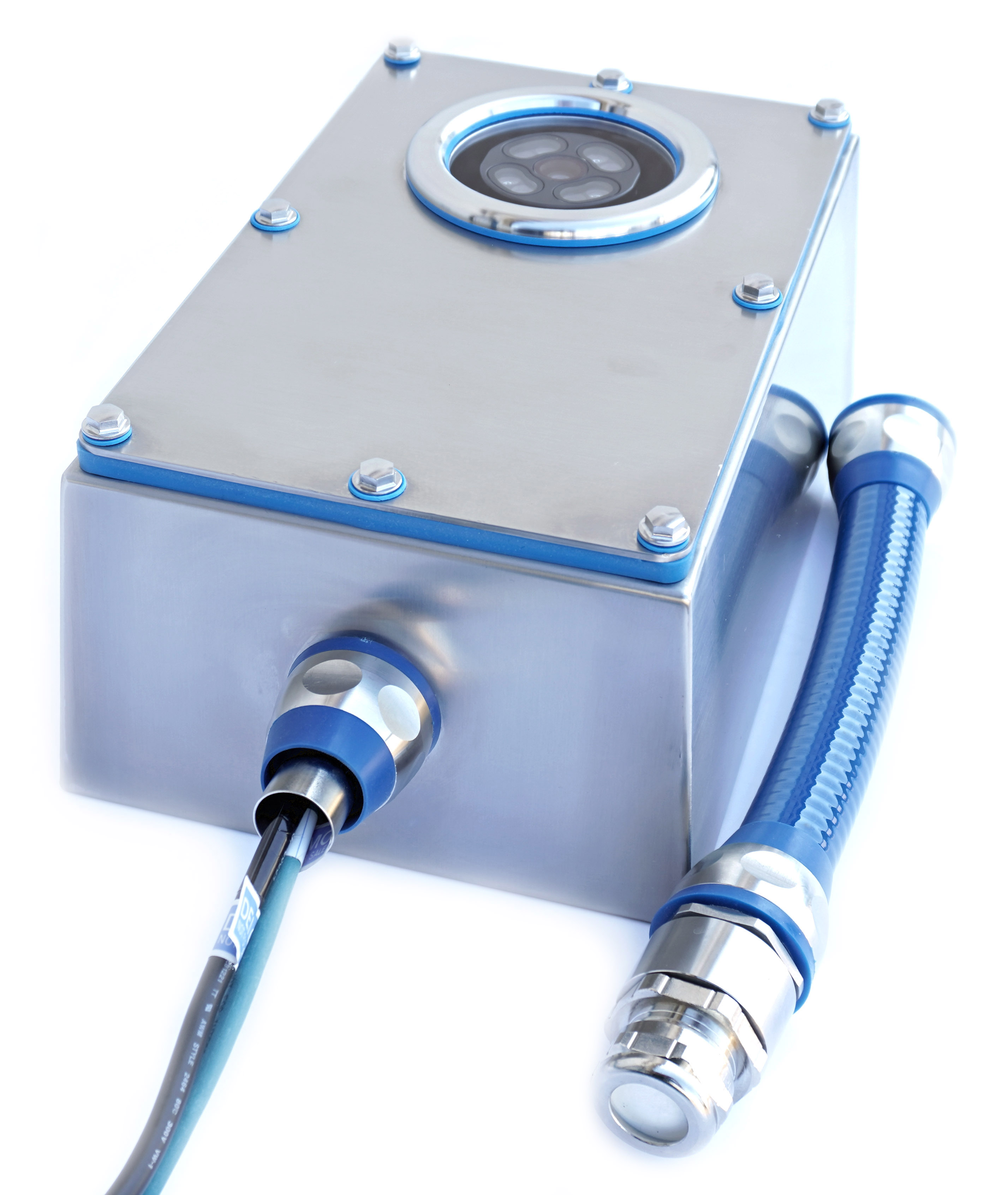

The »Hygienic Machine Vision Building Kit«, a complete stainless steel installation kit for processes with regular high-pressure cleaning, enables the legally compliant installation of image processing components in the food and pharmaceutical processes in accordance with strict EHEDG specifications.

As the camera technology almost always inspects the product from above, strict hygiene requirements apply here in accordance with the Machinery Directive, especially for open production processes and wet cleaning, which is particularly common in meat and fish production. Surfaces must be easy to clean and therefore rounded and every seam must be sealed to prevent bacteria from forming. The hygienic mounting linkage with sealed 90° angles and T-fitting with internal clamping not only allows free positioning of the image processing components, but also internal cable routing, for which EU and FDA food approval is then not required.

The technology was successful at the »inspect award 2024« last year, achieving second place in the »Vision« category.

Hygienic housing for right-angle cameras

The new »IP69k Chamäleon M« in hygienic design offers protection for right-angle sensor cameras and is available in 80 mm and 110 mm heights, allowing vision sensors with built-in optics and lighting to be placed directly behind the viewing window. To ensure that no housing contours interfere, the double-sealed window cover has been designed with an extra-flat design.

In combination with 30 mm housing extensions, the space for C-mount lenses is increased. The matching protective conduit system with a 19 mm inner diameter allows for the protected and hygienic routing of multiple cables and connectors into the control cabinet, where the cables can also be individually sealed.

The housing and its built-in components also offer good heat dissipation.

Compact protection at reduced costs

The »Sparrow« system, with cross-sectional dimensions of 29 mm x 29 mm or 30 mm x 30 mm and a maximum lens diameter of 40 mm, is a flexible technology for common machine vision cameras. The housing offers an interior length of 160 mm and is designed to IP66 protection class.

The system's flat front cover, together with the included 40 mm housing extension, allows for easy adjustment of the lens settings.

Without the extension, the cover is suitable for cameras with S-mount lenses. The cable gland with a closed sealing insert for self-drilling allows for the flexible routing of one or more cables and connectors up to 21 mm in diameter. The system can also be equipped with a simplified tilt-and-rotate mount. This is less robust than conventional milled versions, but is sufficient for applications with lower mechanical stress.

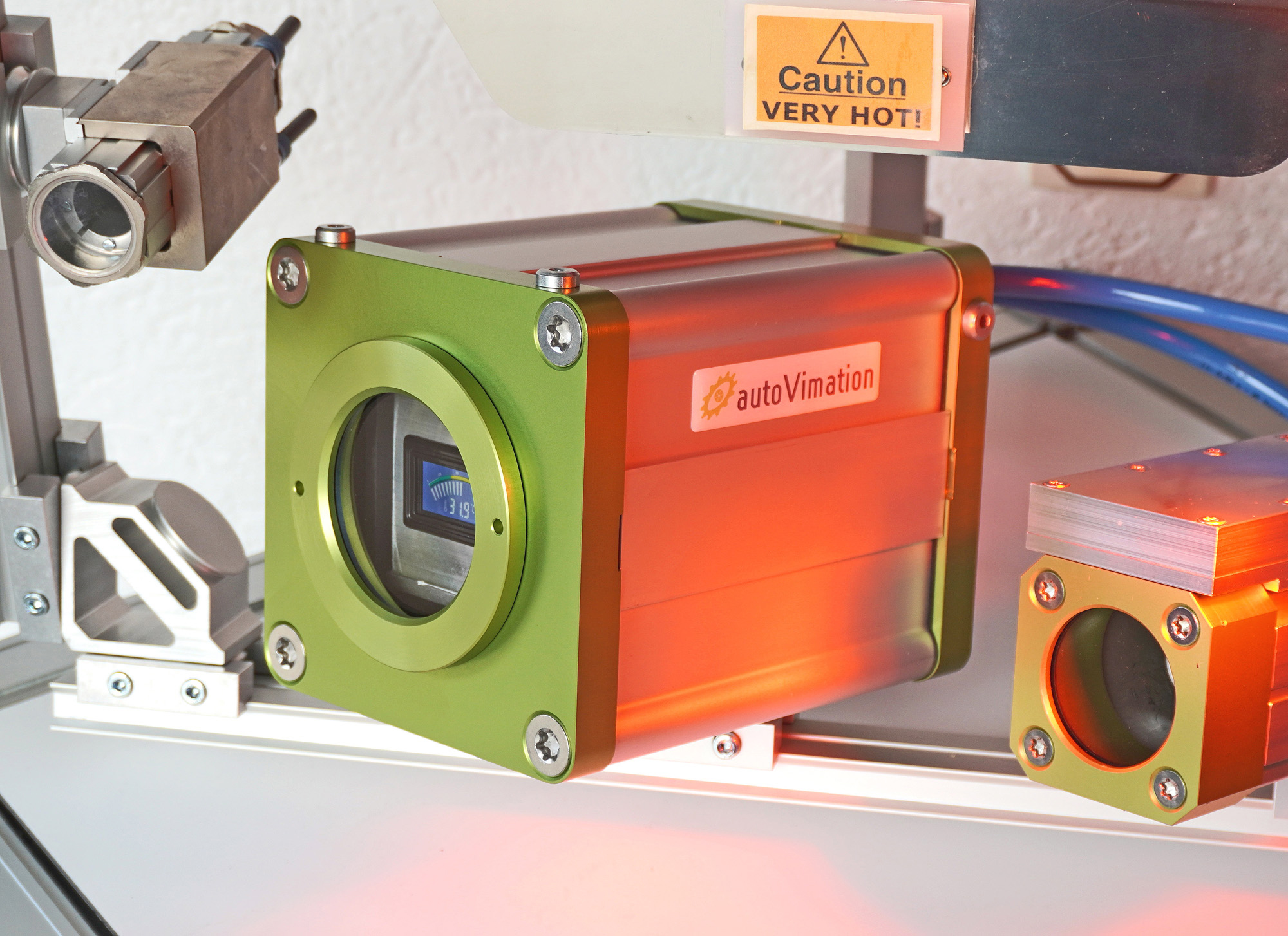

Camera protective housing with water cooling

The water-cooled protective housing can be modularly adapted to customer requirements. The system consists of a cooling unit with a pump, a radiator, a camera temperature monitor, and a fan, and can be operated at distances of up to 20 m.

Various viewing windows, wind curtains, protective shutters, and the Meganova LED ring light are available as accessories. This LED lighting for camera protective housings with good heat dissipation allows the LEDs to be pulsed at 4x brightness thanks to the built-in flash controller. The trigger behavior, gain, and flash duration are programmable up to the limit of the stored LED characteristic curve, allowing a duty cycle of up to 1:1. The system's performance is demonstrated with sharp images captured by a fan rotating at 50 km/h.