Work studies collect data from various processes to organize industrial manufacturing. In particular, the hours of work recorded for manual jobs are a central element of planning, control and payment. Time recording facilitates surveys and analyses of operations. The breakdown of an operation into elementary steps, e.g. reaching, grasping, setting up and joining, is the prerequisite for structured time recording. This enables evaluating a process and iteratively optimizing the total time by reducing individually controllable elements. Work studies have used mechanical or electronic time recording systems to record time by a time sensor.

Automatic time recording for manual assembly processes

Solution

The Fraunhofer IFF has developed an inertial sensor-based measuring system that objectifies and reduces the labor time required to record time. It automatically captures the movements of selected extremities of a worker during work.

The thusly obtained measured data is used as motion trajectories to reconstruct a model of motion. In another step, different process variables, e.g. distances of motion, gripping position and angles of rotation, are determinable from these trajectories and, when necessary, assigned to known sequences of actions. Afterward, times are assigned to the typical elements of the broken down assembly operation.

Functional Principle of Inertial Sensors

The measuring system uses microelectromechanical sensors to determine motion and orientation. Acceleration and angular rate sensors are employed to determine the components of translatory and rotatory motion. Additionally, the direction of the geomagnetic field is registered. The sensors are configured in a triaxial array. Data processing compensates the undesired components of gravitational acceleration and the earth`s rate of rotation captured by the sensors and subsequently determines motion variables such as position, spatial orientation, velocity and effective acceleration.

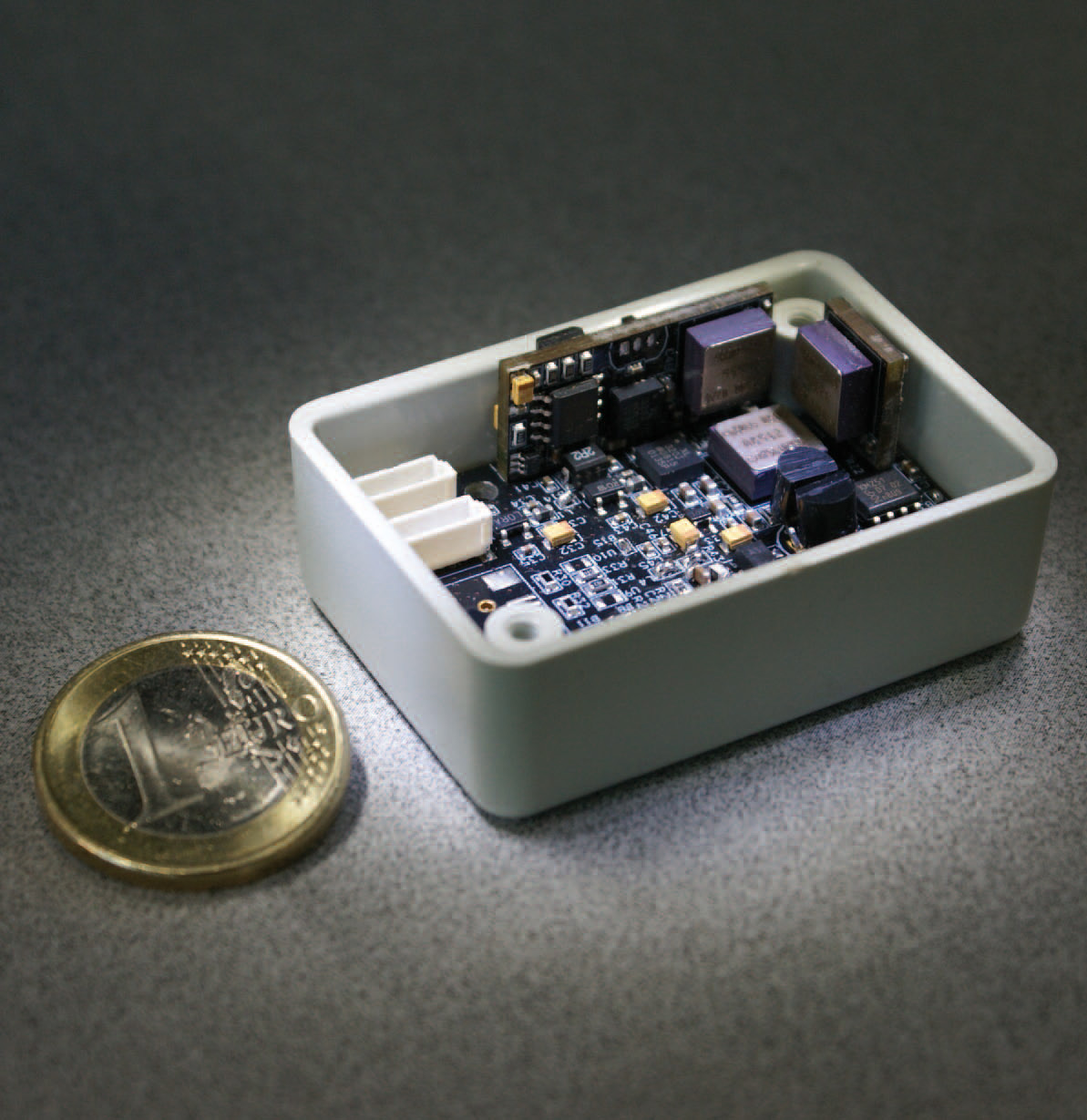

The advantage of inertial measurement systems is their independence from a reference infrastructure. Alternative motion capture systems, e.g. GPS, camera and ultrasonic systems, absolutely need a reference infrastructure, e.g. satellites for GPS, to function. Attached directly to a moving object and without an external reference system, an inertial sensor module having the size of a matchbox (see Fig. 2) determines the object´s spatial orientation and position.

Time Recording System

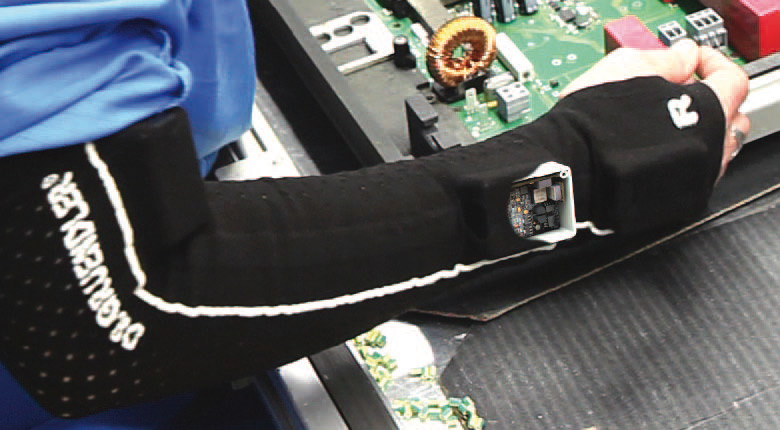

A special sensor oversleeve has been developed for the defined arrangement of one sensor apiece at the hand and at the upper and upper arm. Snug yet comfortable, the anatomically molded oversleeve enables the sensors which it bears to exactly follow a worker´s movements and is simultaneously comfortable to wear.

Its simplicity and functional principle make the inertial sensor´s features less than ideal. Thus, measuring errors mount as the measuring time advances. A correction algorithm based on a biometric model of the human body was developed for this application to compensate for errors.

Consisting of two oversleeves and six inertial sensors, the system is supplemented by a PC application. The PC computes and reconstructs motion sequences on the basis of the sensor data and the determination of the related times. The application provides an easy option to structure a manufacturing operation and a tool to teach measuring points directly at the assembly area. A system that manages the recorded assembly sequences and motion structures makes it easier for users to document and analyze time recording.

Benefits

- Objectified analysis of assembly processes

- Automatiic recording and determination of distribution times

- Significant reduction of labor required for work studies

Outlook

The system´s design has restricted its use to seated workplaces. Future stages of development are intended to extend the range of applications to jobs in manufacturing cells with movable work areas.

Other Application Scenarios

Time recording in work studies of manual assembly processes is a scenario for the application of inertial sensor-based motion capture. When it is extended with a detection of postures in conjunction with weights handled and forces applied and an examination and analysis of sequences of action, it supports studies of ergonomic workplace design. When physiological parameters, e.g. pulse, blood pressure and heart rate variability, are measured, workloads and stresses can be analyzed.

Images

- Fraunhofer IFF

- Photos: Lintje GbR