Quality assurance with image processing

Numerous Fraunhofer institutes research and develop in the field of image processing and optical or acoustic testing for quality assurance. At the Control 2023 booth, which is coordinated by the Fraunhofer Vision Business Unit, current new developments from various fields will again be on display.

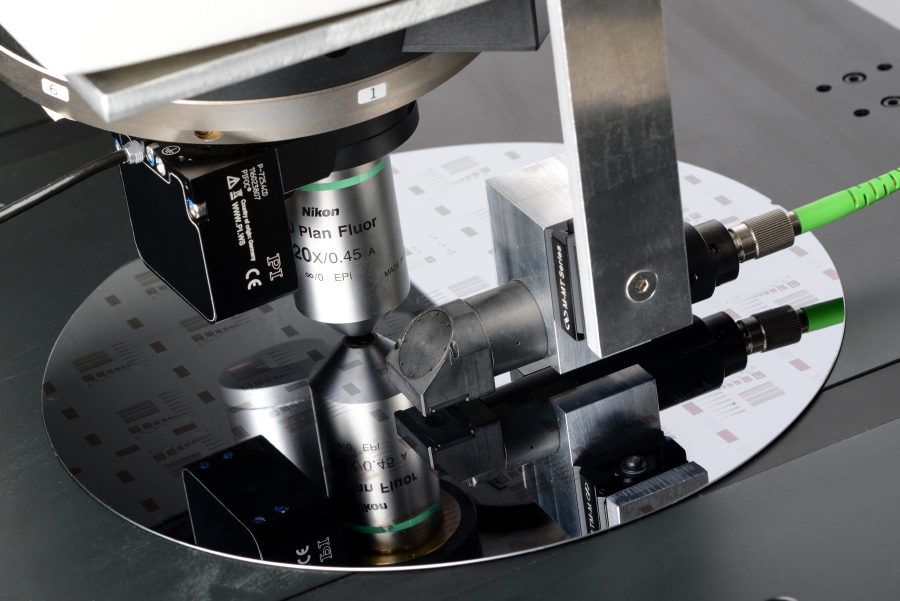

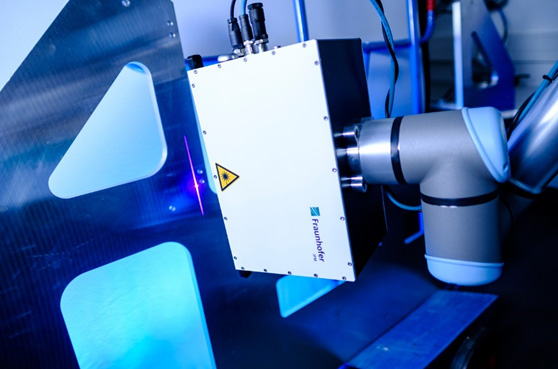

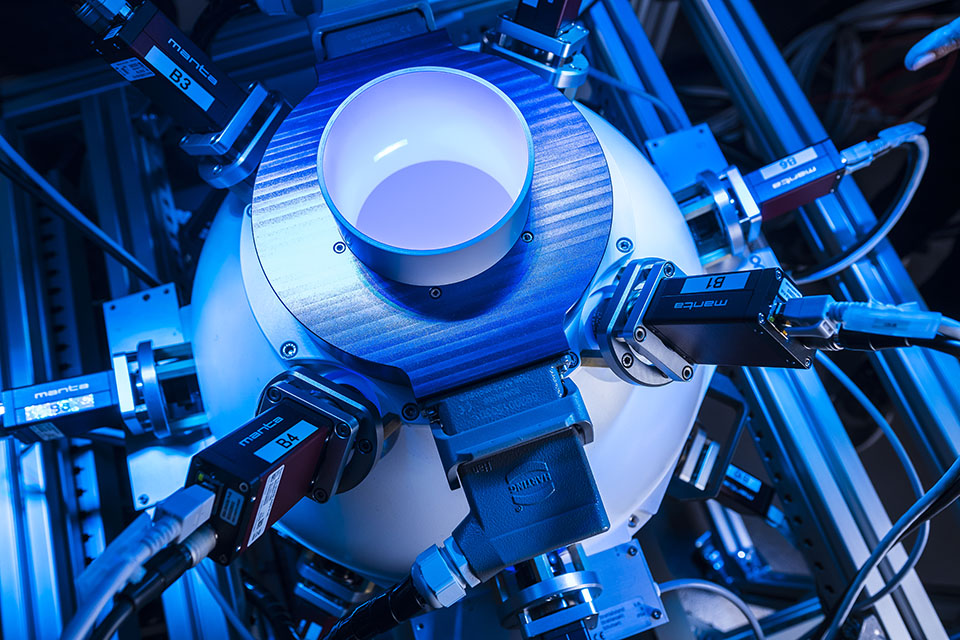

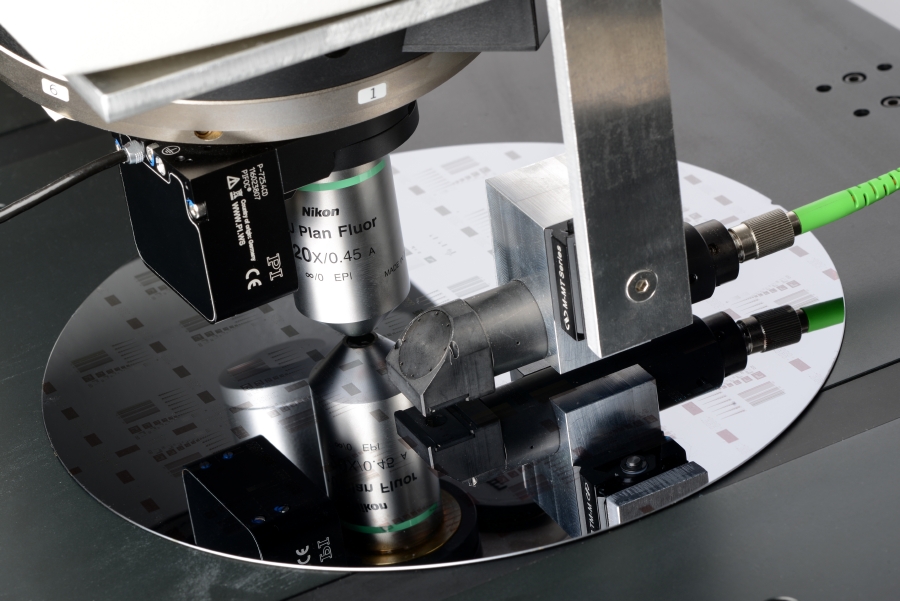

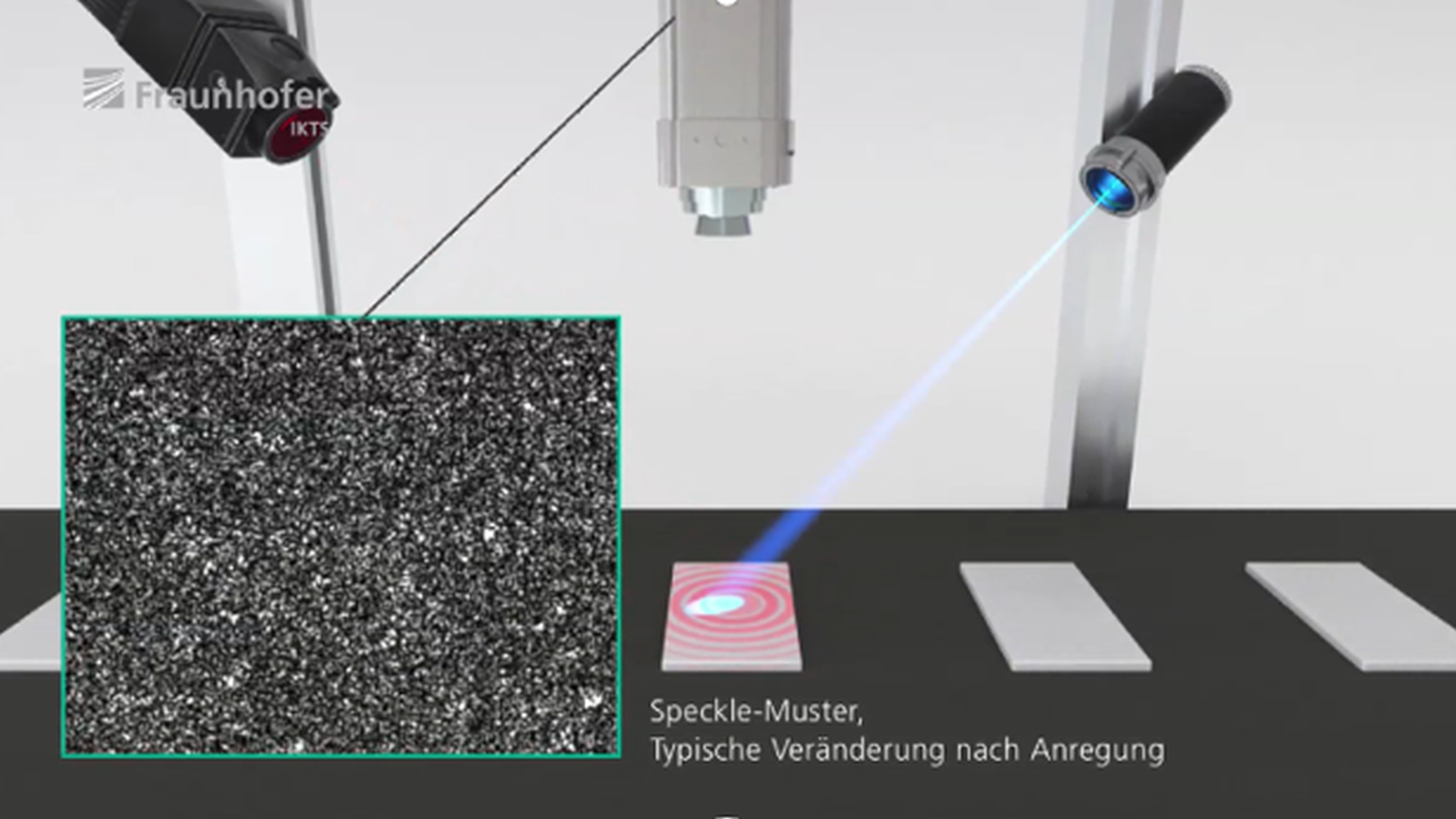

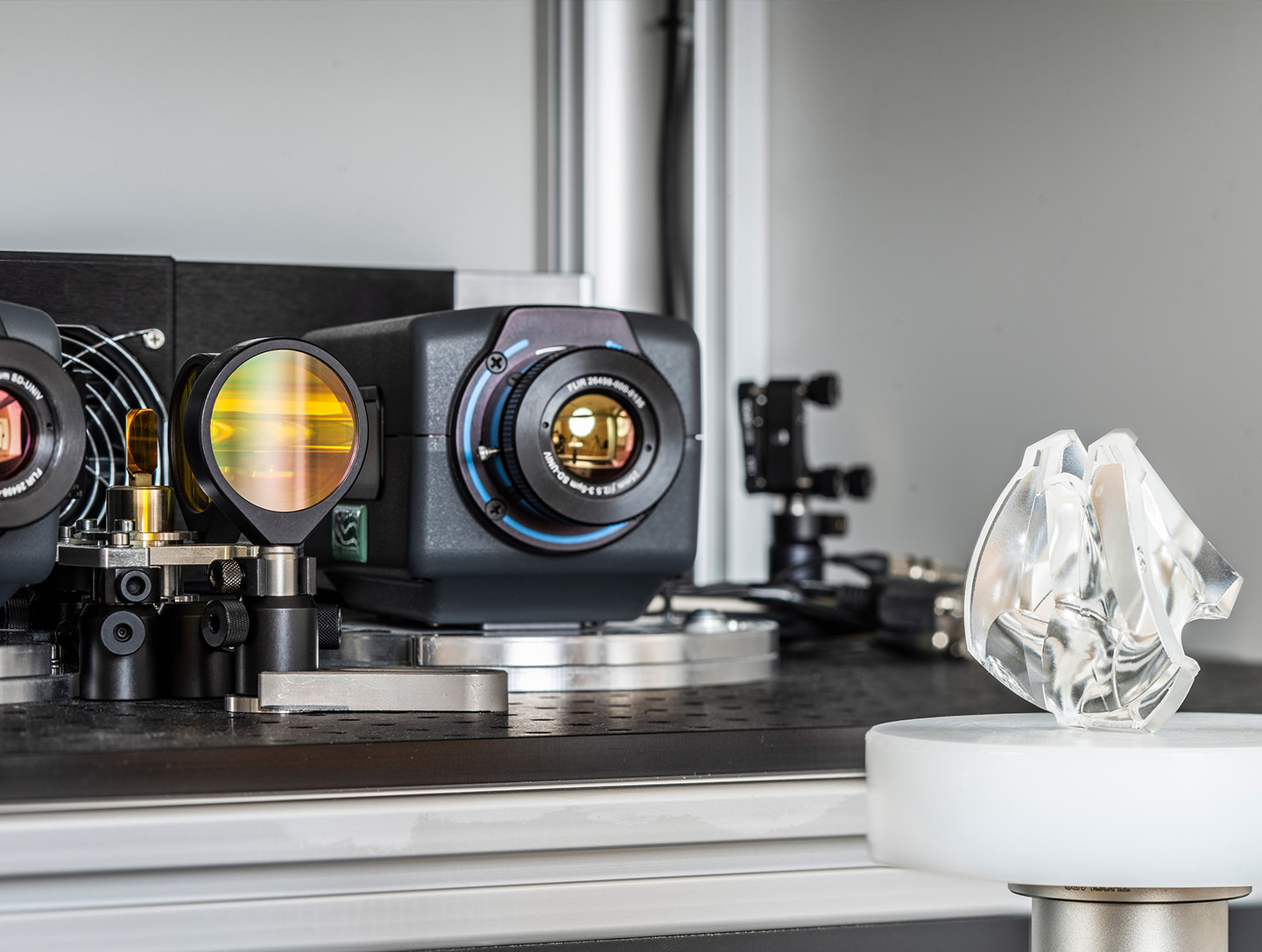

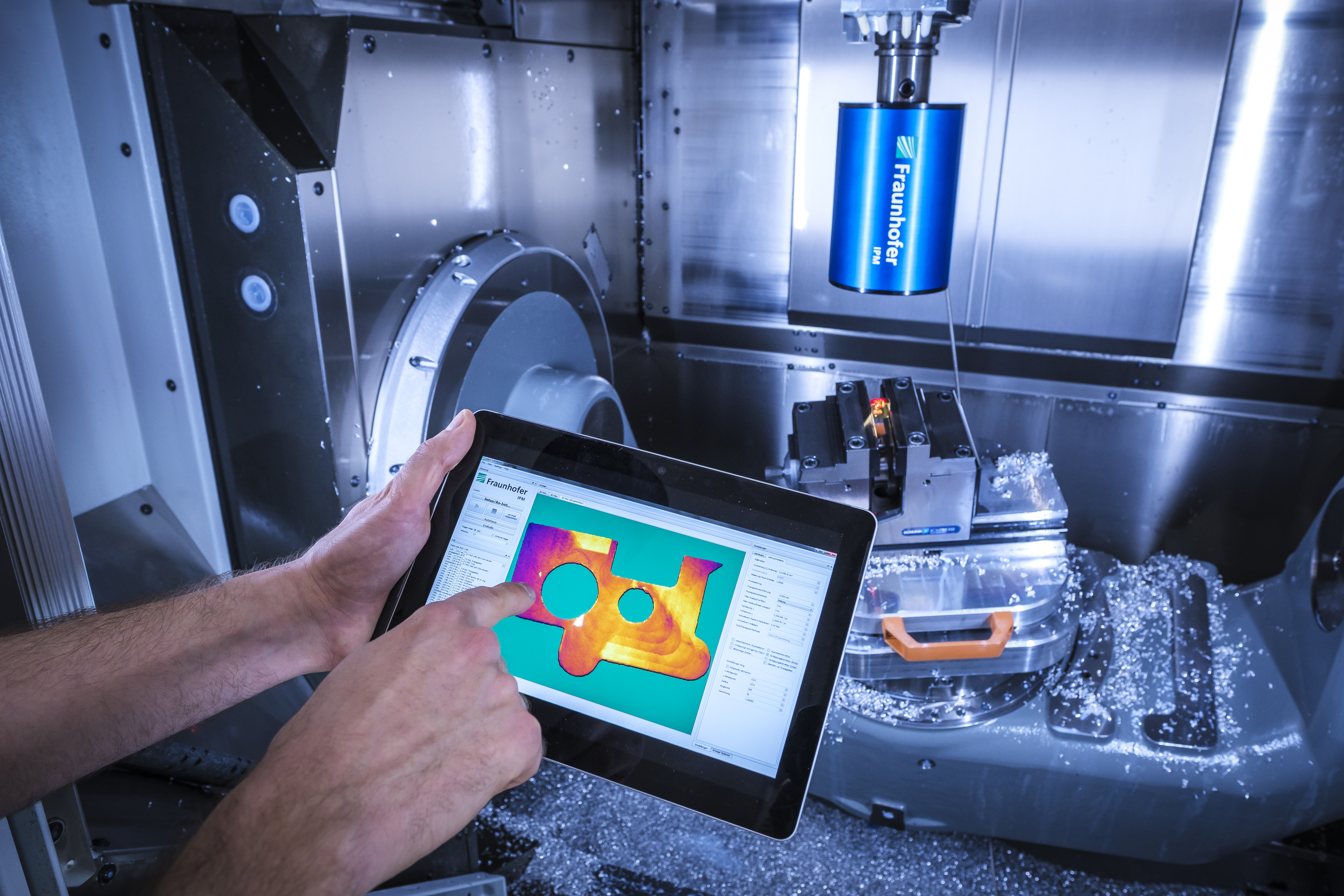

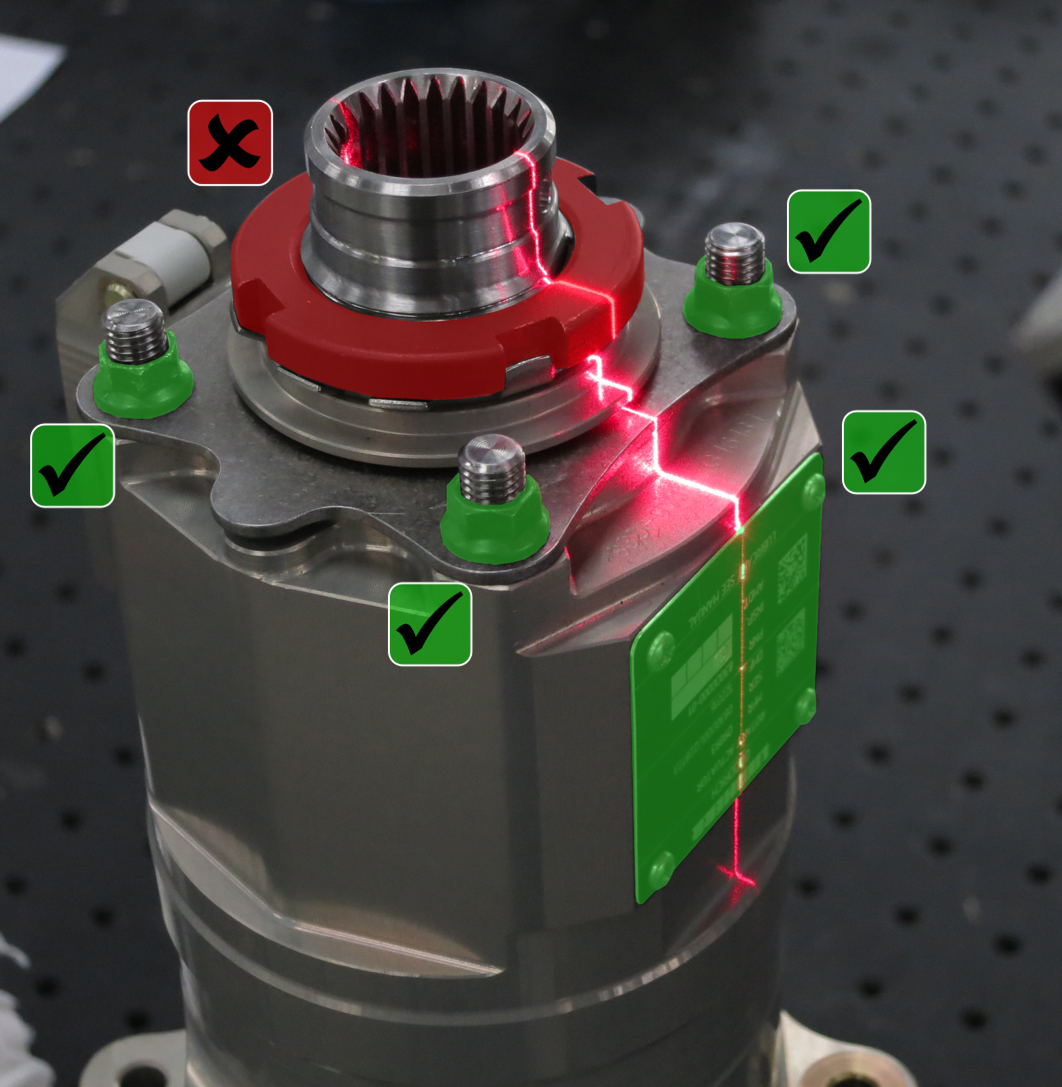

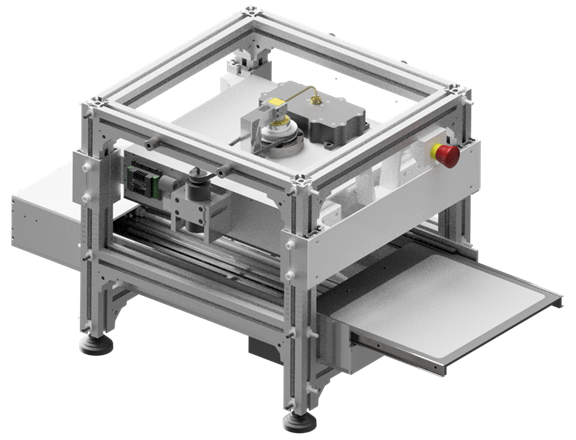

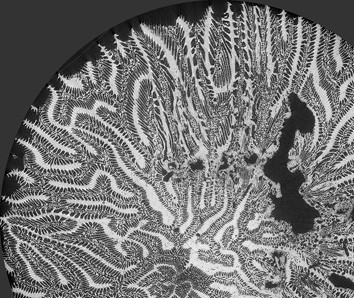

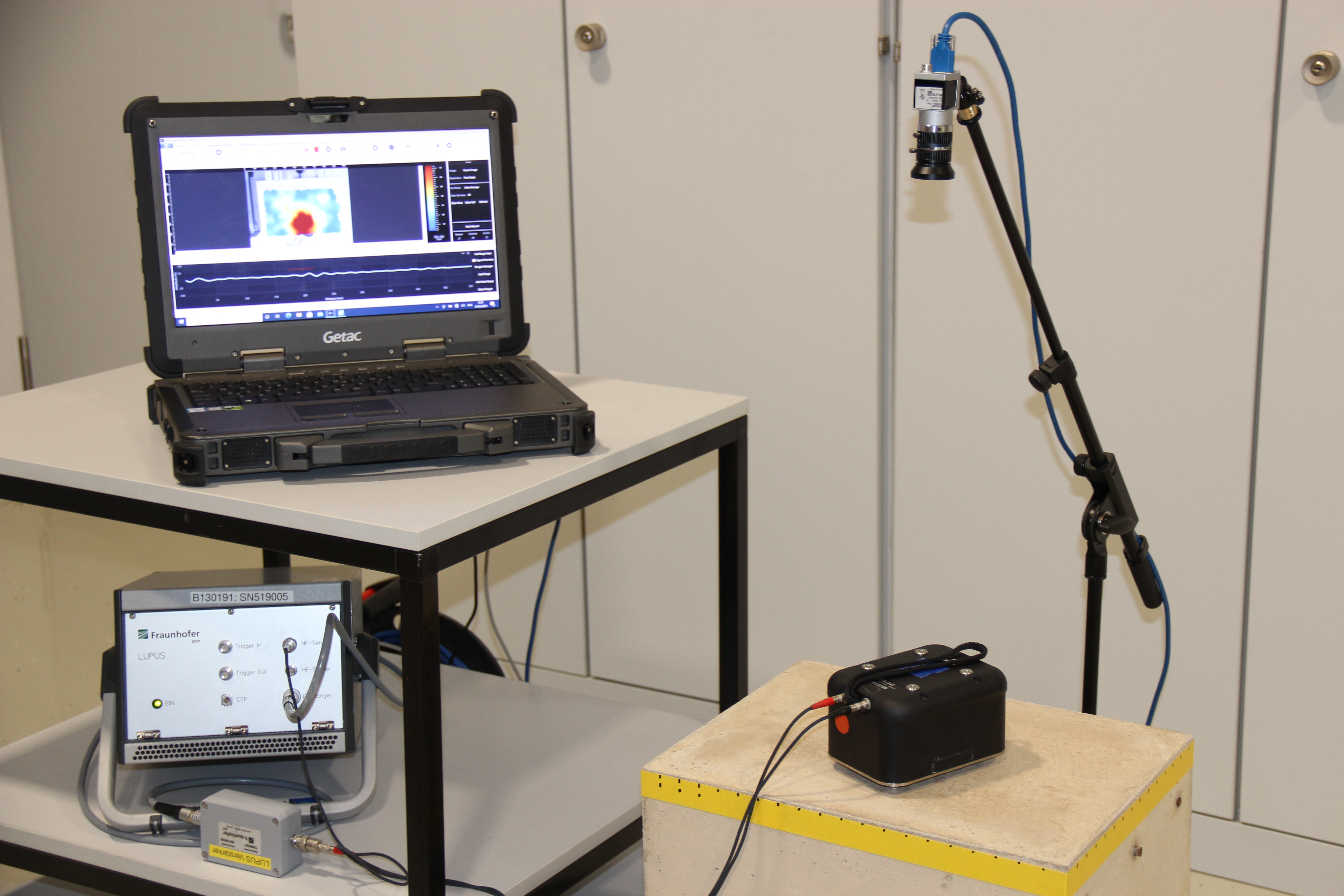

This year, we will present exhibits from the areas of inspection and characterization of surfaces, optical 3D measurement technology, inline measuring and testing and component identification, augmented reality and spectroscopy. In addition, new developments for inspecting components below the surface or inside the material using technologies such as X-ray, terahertz, ultrasound or high-frequency radar will also be on display.

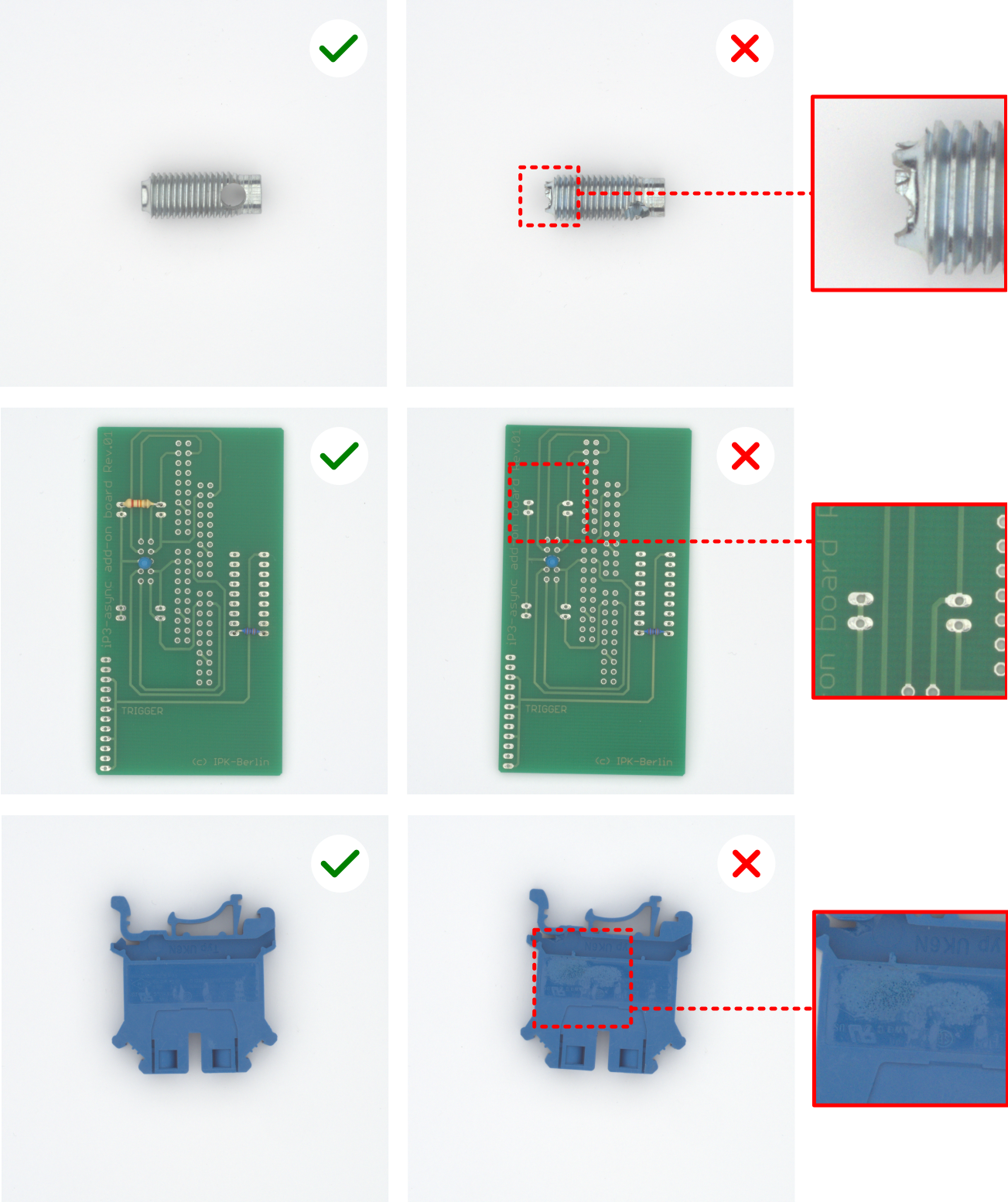

Numerous exhibits work with artificial intelligence or machine learning methods, so you can also get an overview of current trends here.

Highlight: Demonstrating acoustic monitoring by playing air hockey

One highlight comes from the field of acoustic monitoring, which can also be used for quality assurance, often in addition to optical testing methods. An air hockey table will be presented for this purpose: in a game of air field hockey, visitors to the trade fair will be able to observe how pucks that apparently look the same and sound very similar can be reliably distinguished on the basis of their sounds and with the help of machine learning methods.