Where can industrial image processing be applied?

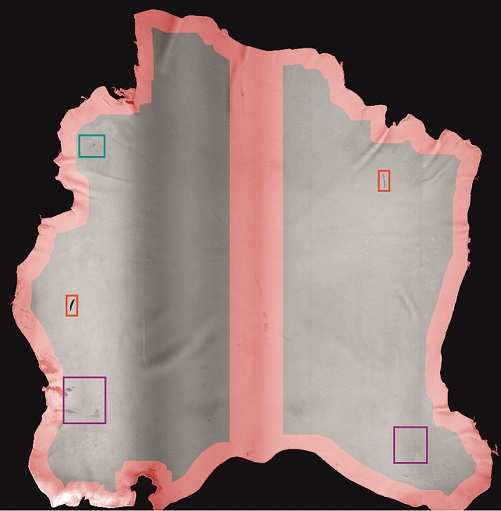

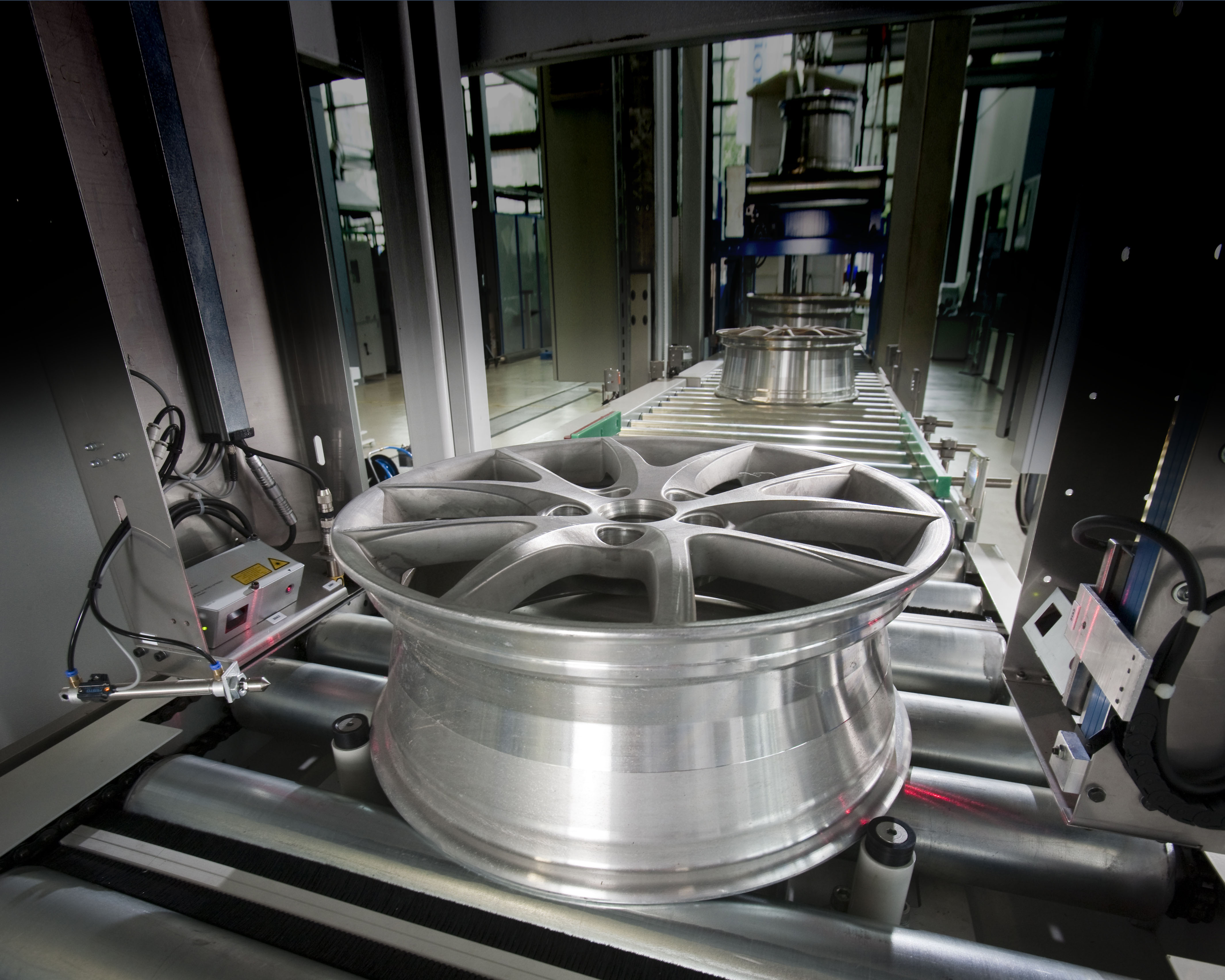

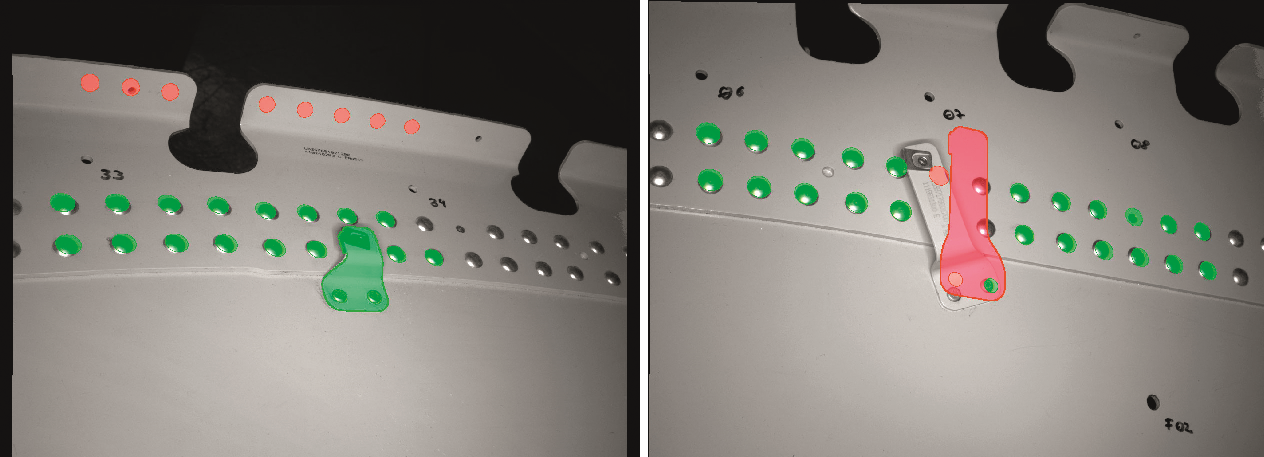

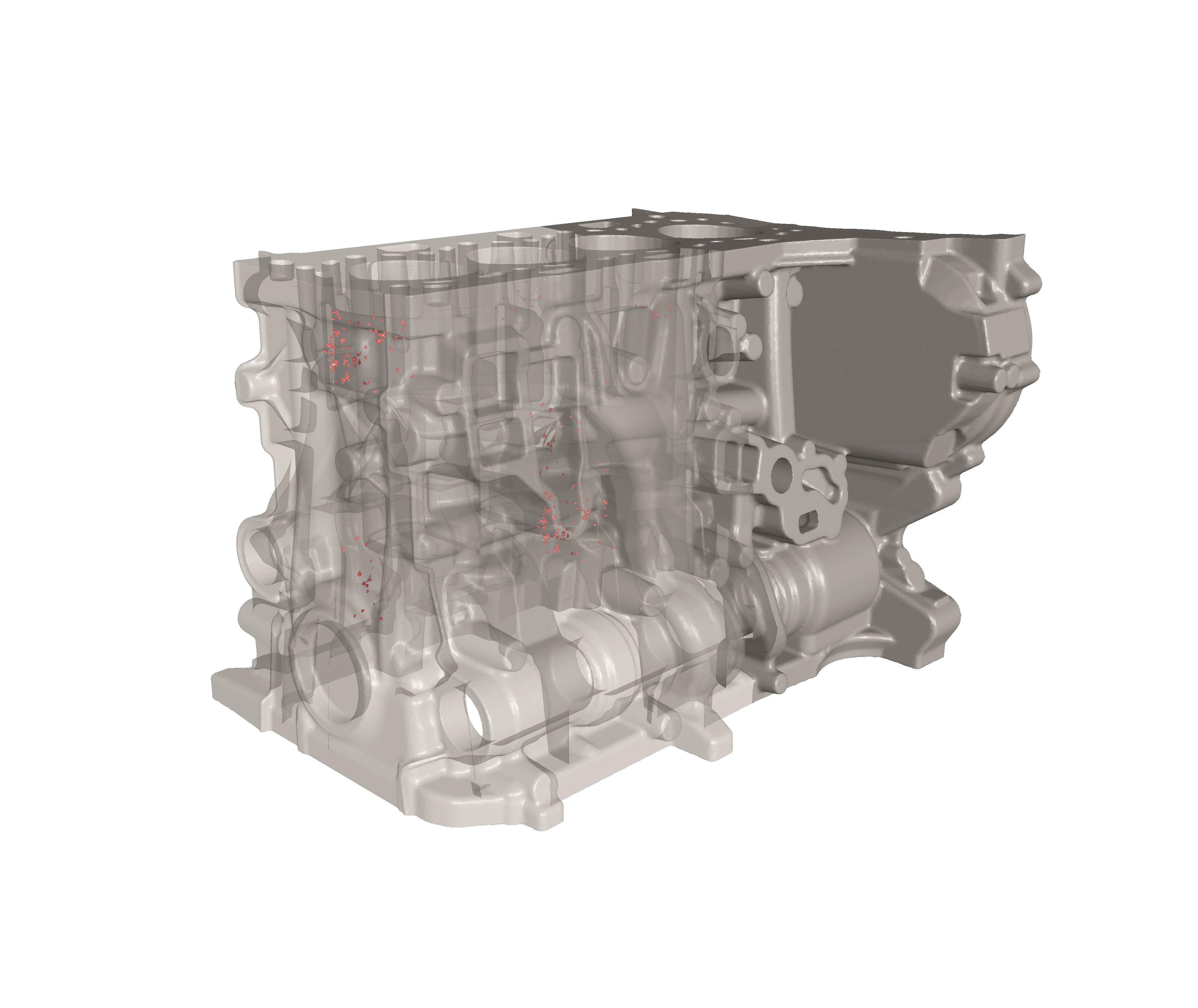

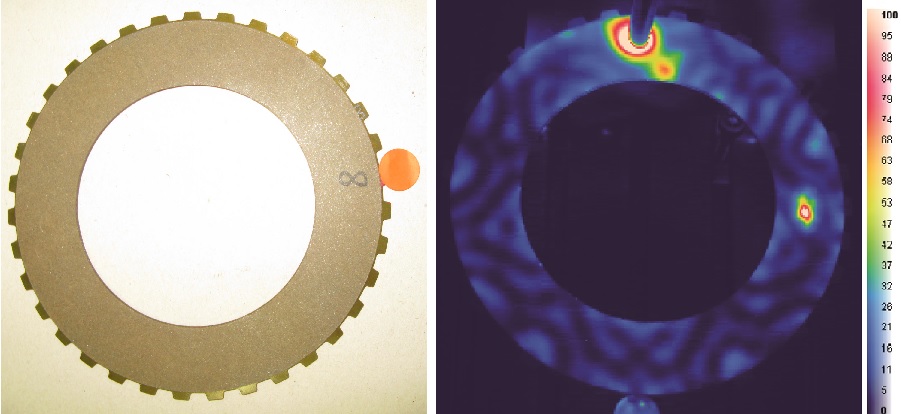

The possible uses of digital image processing in industrial applications are wide-ranged and are therefore on the focus of many different industries. One main area of application is industrial quality assurance in manufacturing or outgoing inspection etc.

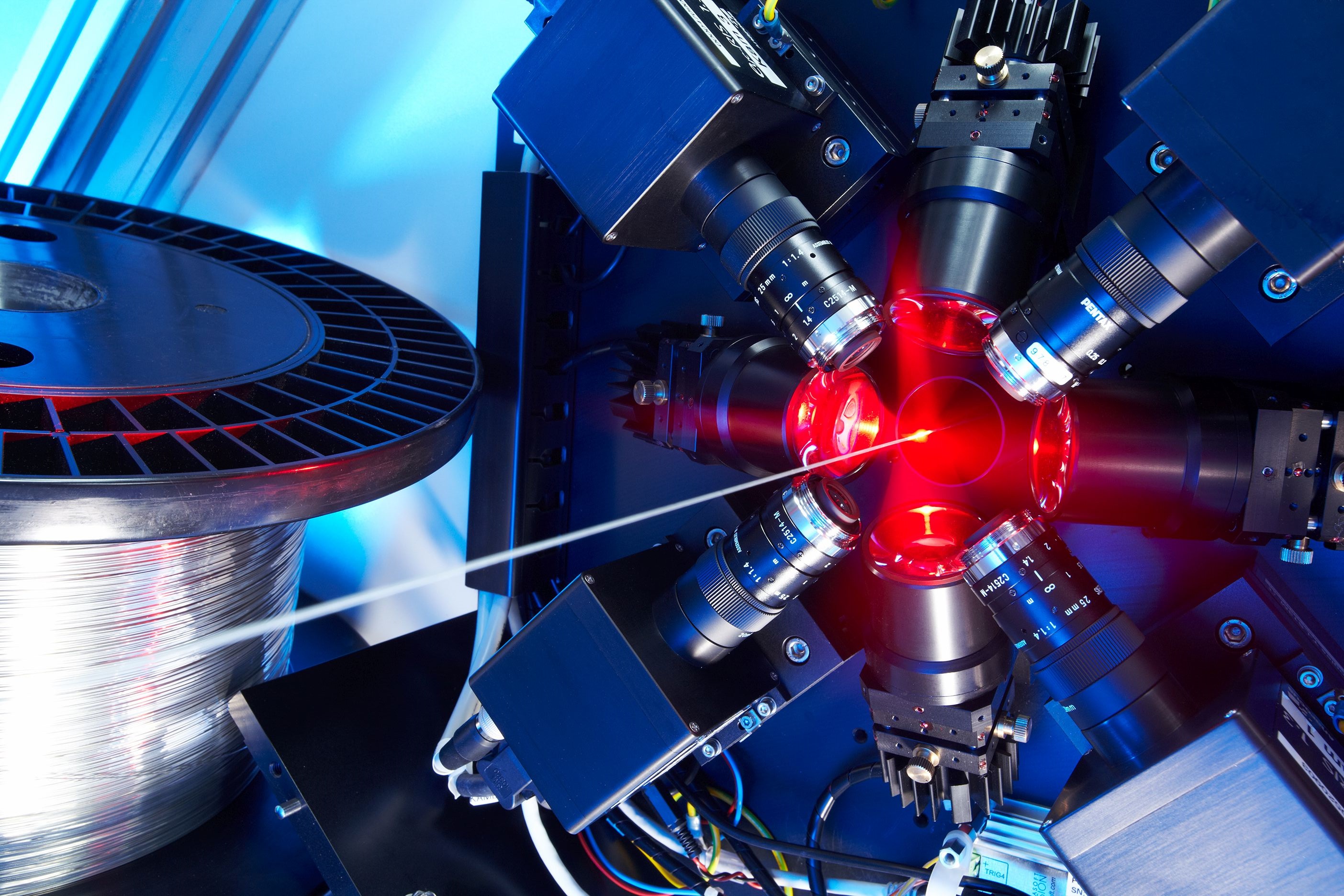

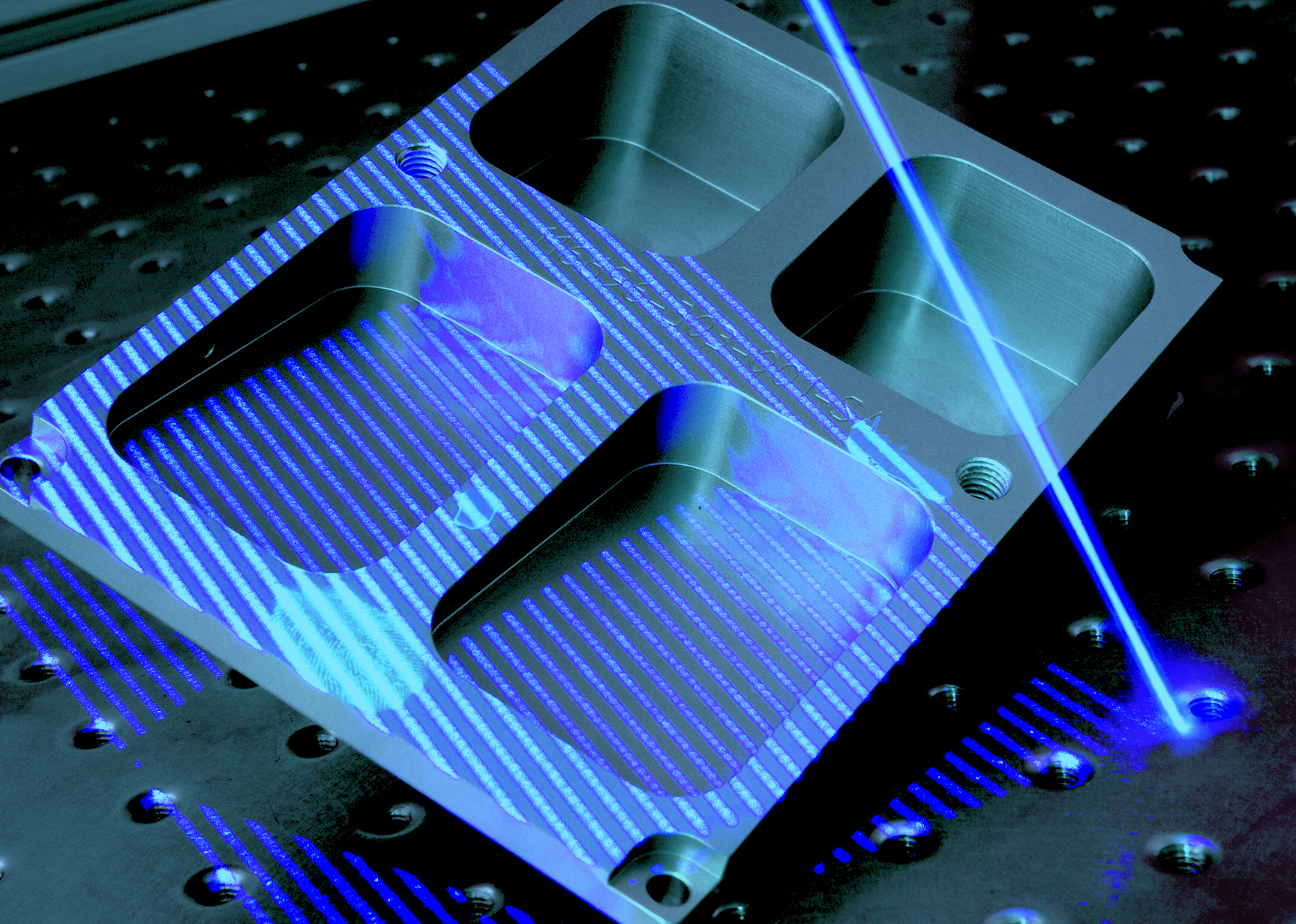

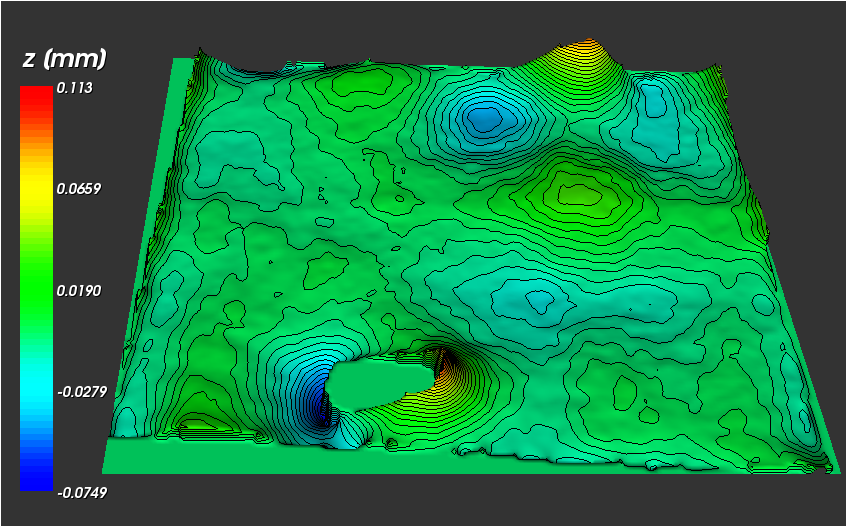

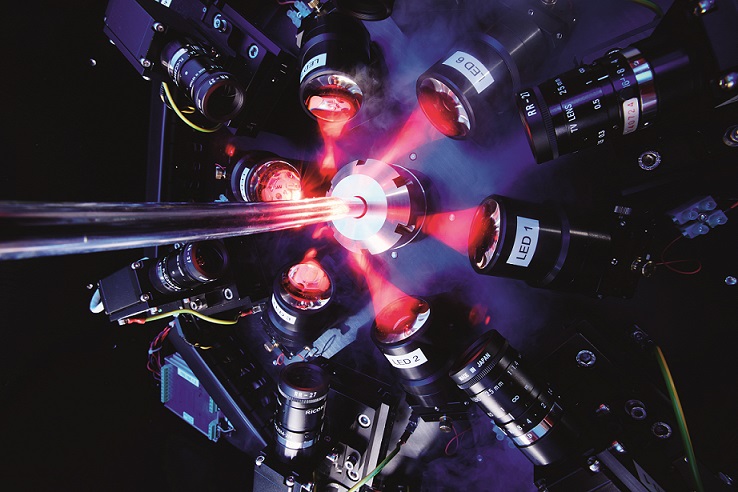

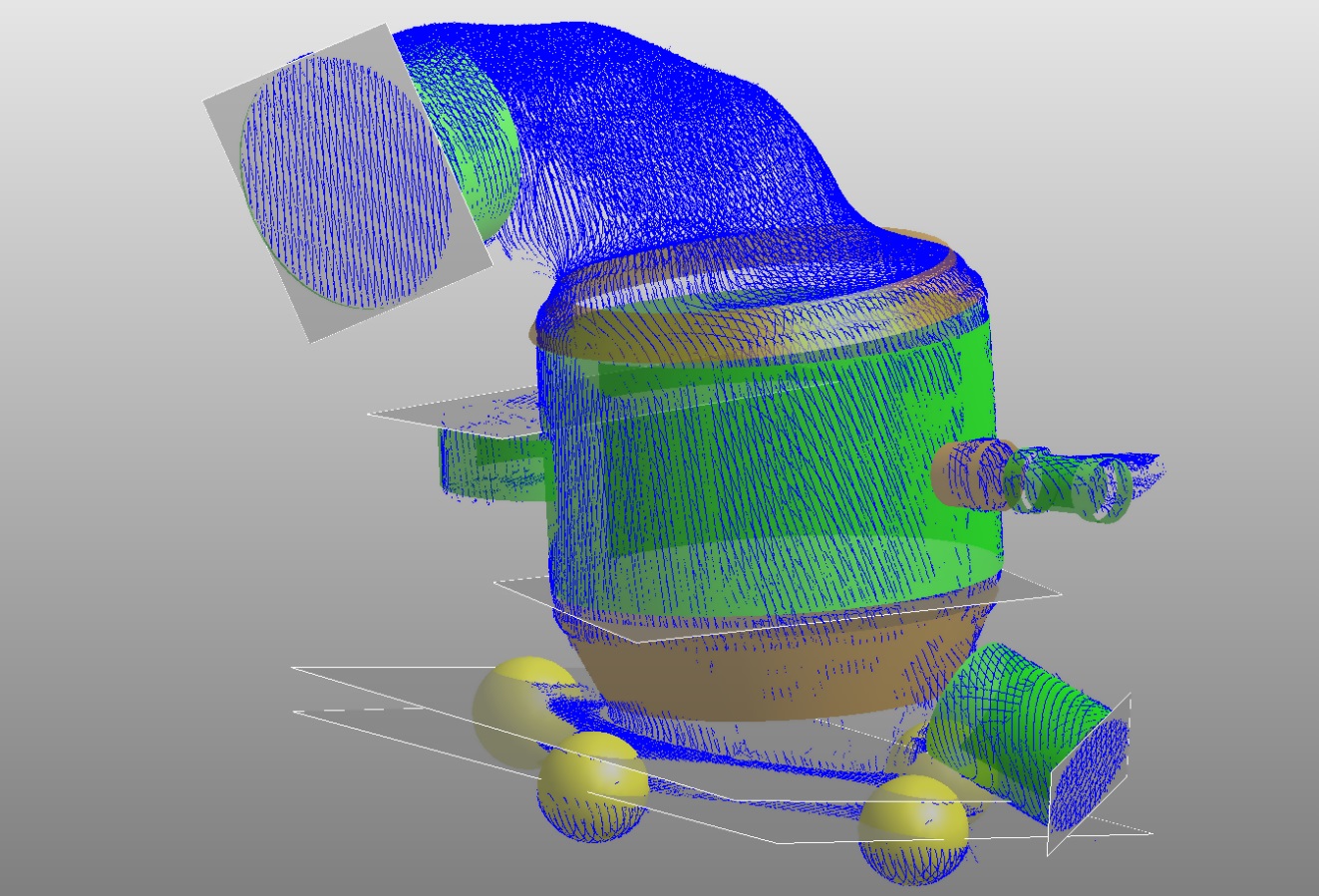

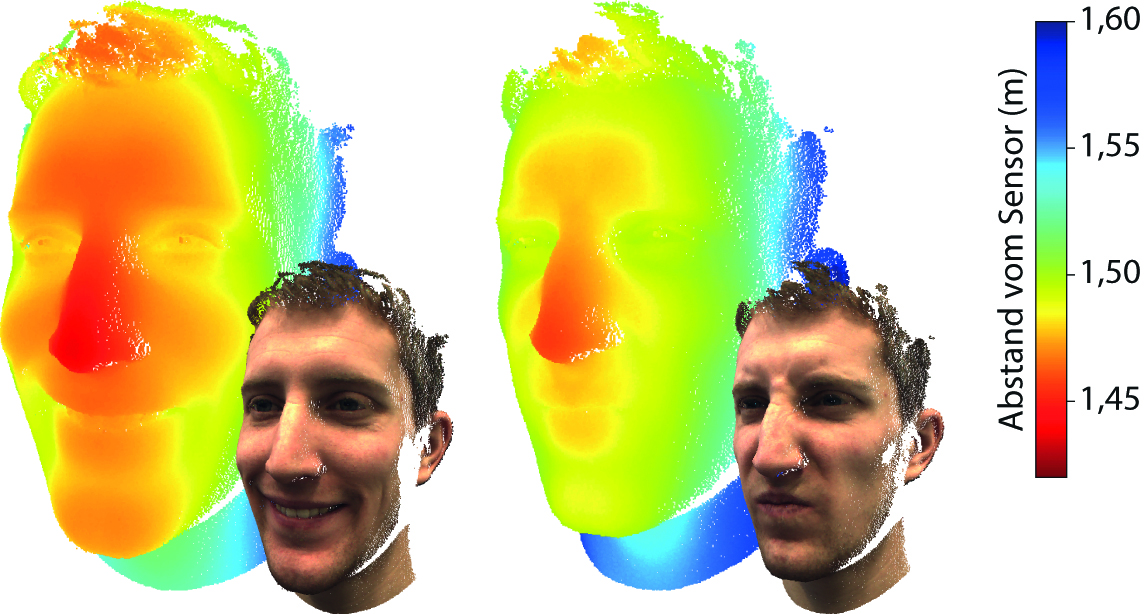

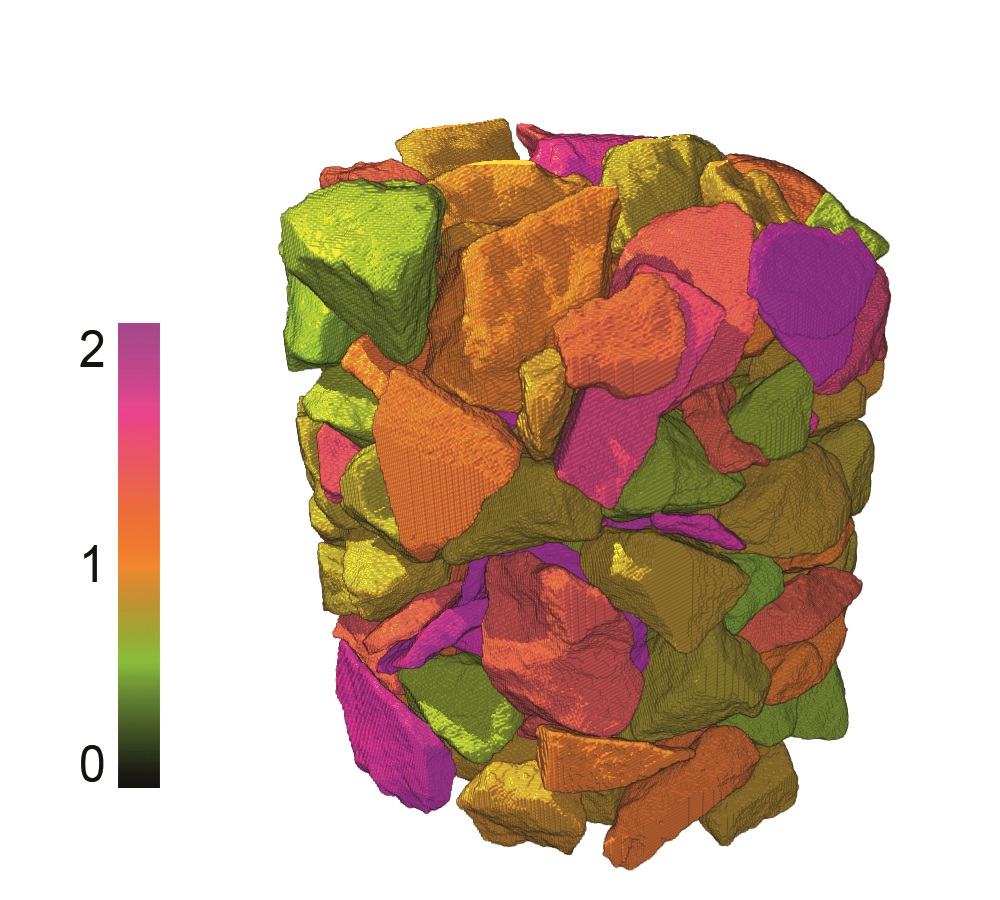

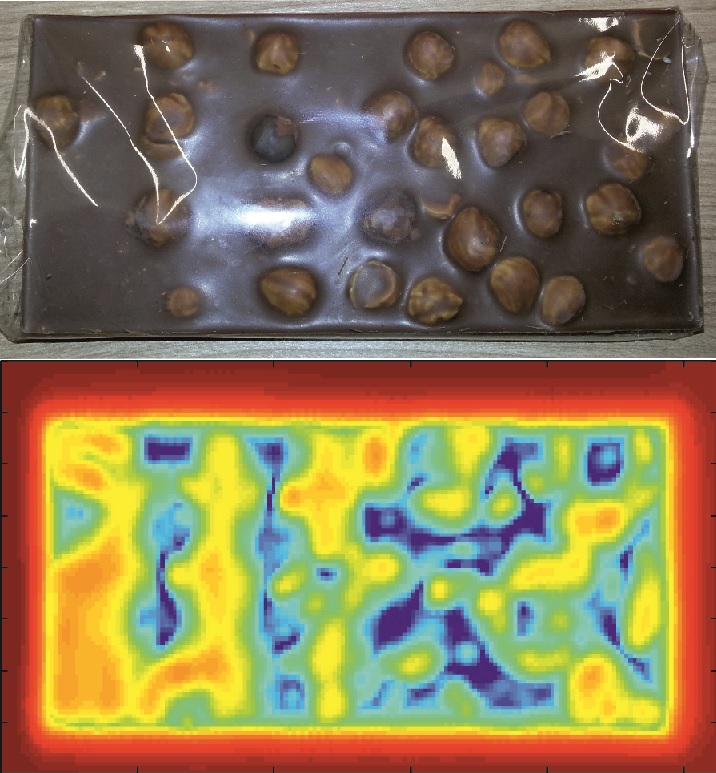

The spectrum of technologies ranges from the inspection and characterization of surfaces, optical 3D measurement methods and X-ray technology to heat flow thermography, terahertz measurement technology, methods of non-destructive testing or hyperspectral image processing.