The Fraunhofer IPT, Aachen, is coordinator of the Aachen 5G-Industry Campus Europe, which is the first location in Europe equipped with a comprehensive 5G network to research and demonstrate the possibilities of using 5G in production.

5G offers novel opportunities for the manufacturing industry in addition to mobile telecommunications. In addition to transmission bandwidths of up to 10 GBit/s, the low latencies of up to below 1 millisecond in particular are outstanding features of 5G, which will enable mobile communications to find a wide range of applications in production for the first time. Wherever increasingly complex parts such as engine components place ever greater demands on the controllability of manufacturing processes, 5G offers new ways of monitoring the processes with wireless sensors and controlling them in real time. Possible applications can thus be found in areas such as turbomachinery construction, medical technology, vehicle construction, tool and mold making, the manufacturing industry, sensor manufacturers, and others.

In addition, the communication infrastructure provides flexible cloud environments to enable complex machine learning applications for quality assurance. The »5G-Industry Campus Europe« is one of the first locations in Europe to be equipped with an area-wide 5G network in order to fully research and demonstrate the diverse possibilities of using 5G in production. In addition to setting up the research infrastructure, the funded project will investigate various practice-relevant issues from the complete spectrum of production technology in the fully equipped machine shops of the research institutes, ranging from 5G sensor technology for monitoring manufacturing processes to mobile robotics and logistics to cross-site production chains.

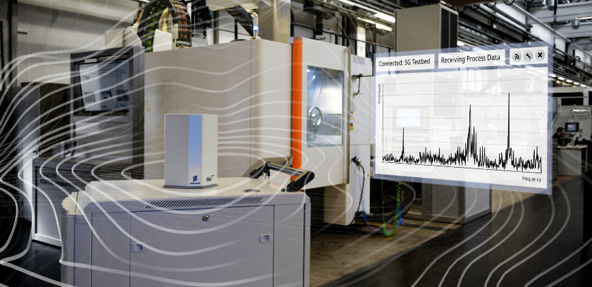

Possible use cases from the field of industrial process monitoring and control are, on the one hand, the application of a vibration sensor on a production part for intelligent anomaly detection, and, on the other hand, an AE sensor (acoustic emission sensor) for monitoring tool wear in a drilling process. A flexible sensor-cloud communication structure is currently being developed for the use cases as part of Fraunhofer projects, which will significantly increase the potential for developing complex machine learning applications for quality assurance.

The new 5G mobile communications standard is characterized by extremely low latency, high data transmission rates and the ability to operate numerous devices simultaneously in tightly defined radio cells. With the help of a system of smart sensors, a flexible cloud environment and a communication infrastructure via 5G, highly complex processes can be monitored and controlled wirelessly and in real time in previously unknown proximity to the process. Signs of wear of the tool head as well as process disturbances and quality deficits of the component can be detected at an early stage and intercepted by instantaneous control of machines and process chains. This ensures the quality of the product and saves enormous costs due to reduced scrap or necessary reworking. 5G thus serves as an enabler for machine learning applications and helps ensure continuous availability of data through improved networking of production machines and IoT platforms and the integration and provision of powerful computing resources such as GPU clusters, thus enabling state-of-the-art AI methods such as machine learning.

More on 5G-Industry Campus Europe

For more information please follow the link to our website